Many are afraid of it like fire, but for me personally repair is wonderful. This is an opportunity to realize new ideas, transform the space around. But before choosing a wallpaper, furniture or curtains, it is necessary to go through the inevitable stage, including the preparation of surfaces for finishing. It was at this time that these terrible words were used for many: plaster, putty, primer, self-leveling floor, etc.

Perhaps any adult, even one who has never encountered repair, imagines what putty is and why it is needed. Simply put, this is the final leveling layer on the walls before painting or wallpapering. And although after the repair of the putty is not visible on the walls, a lot depends on it. If it is of poor quality or applied without observing the technology, the walls will soon go cracked or the putty will begin to depart in layers, along with the finish coating.

Why add glue, soap and other ingredients to the putty

The content of the article

- Why add glue, soap and other ingredients to the putty

- How to make putty more elastic

Having come to any hardware store, you will see many types of putty from a dozen manufacturers, domestic and foreign. Advertising posters report on the innovative and unique properties of their product.

People were engaged in construction many centuries ago, and as practice shows, a masonry mortar of centuries ago, which was based on the simplest components, for example, egg yolks, are much stronger than modern high-tech cement compounds produced on the most modern equipment.

Reference! The most common universal gypsum putty in construction for most manufacturers by more than 95% consists of ordinary chalk and a binder based on the same components that are part of the well-known adhesive PVA. And only less than 5% are specific additives, such as antifungal components and plasticizers.

In plasticizers, there is also nothing innovative, these are compositions very similar to ordinary soap, but without fragrances and dyes.

The compositions of putties of most large manufacturers are almost identical and brought to perfection. Therefore, if you have to repair, the problem of getting a good putty is unlikely to bother you.

But this was not always the case, some 30 years ago it was a great success to buy ready putty, it was necessary to improvise. In Soviet-era magazines you can find many recipes for homemade putties. They used PVA glue and soap as a binder and plasticizer.

How to make putty more elastic

Buying a quality putty is not a problem, but sometimes, in order to save money, we get a low-quality product. As a rule, these are expired formulations, violated storage conditions or outright counterfeit. Under putty of low quality is understood as a product that does not dissolve well upon hovering and has low elasticity.

You can return the goods to the seller and purchase putty of normal quality. Bad materials can not only spoil the entire repair, but also the nerves of the master when working with them.

But there are times when you need to somehow work with the material that is available. In this situation, only one thing can be advised: try to somehow rectify the situation and make the putty more elastic.

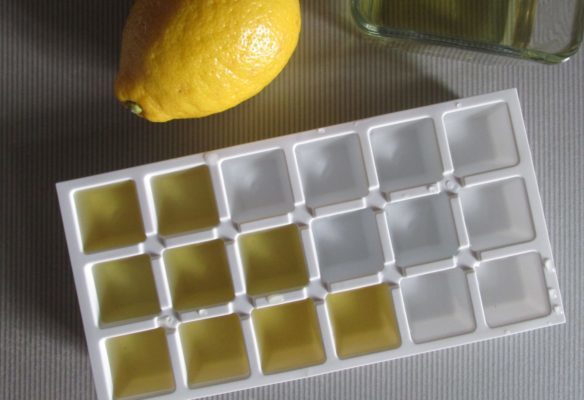

As you already know, PVA glue and liquid soap or any detergent will help you. How much to add in a particular case can only be determined experimentally. Carry out an experiment with a small amount of solution and you will notice how the elasticity of the putty noticeably increases.

Attention! If you overdo it with PVA glue, the putty will become better, the adhesion will improve, but the interlayer sanding of the walls will be very difficult.

That's all for me. I wish you only quality materials and perfectly even walls.