In the summer (and indeed at any time of the year) it is pleasant to have a barbecue, washed down with any of the drinks. The brazier can be built of stone or bricks, but it is much more interesting to cook goodies on something that has a prestigious look. Reliable, durable and quite decent outwardly barbecues are obtained from gas cylinders. The process of their manufacture is simple, and today we will figure out exactly how to make such a device without much noise and dust. Let's consider the simplest option.

Arguments in favor of a balloon design

The content of the article

- Arguments in favor of a balloon design

- What you need to work

- Which balloon is best for

-

Step by step description of the process

- How to dismantle the valve and what to do next

- Marking and cutting

- How to attach a brazier legs - in a good way

- The better to protect the brazier from corrosion

The material from which the cylinders are made is ideal for our purposes, its dignity:

- Suitable for use at high temperatures.

- You can not only fry meat, but also bake vegetables, fish, and also, with minor modifications, use the grill in the smokehouse mode.

- Relative fire safety and ease of use, because after the cooking process is over, there is no need to fill the coals with water - cover it with a lid and it's done.

- The cheapness of materials, and, as a consequence, the finished product, because if you buy sheets of metal with a thickness like the walls of the cylinder, it will be much more expensive. And it is quite possible that a gas cylinder that has served its time is already waiting in the shed.

- Comparative ease of making a barbecue. No global transformations will be required during the work and it will take a little time for it.

From disadvantages only two can be noted:

- The design turns out to be rather bulky and massive, but this is already a question of who and how much porridge ate. And the fact that the grill itself is large is perhaps even a plus if there are a lot of guests and the appropriate amount of meat needs to be prepared.

- Some people do not like the semicircular shape of the bottom of the barbecue, allegedly inconvenient when lighting firewood.

For some, the very shape of the balloon, and, consequently, of the barbecue - they say, the aroma of meat does not fully unfold. I think this argument is far-fetched - everything turns out to be tasty and aromatic, as if it was being cooked on an ordinary stone grill. And the food is baked very evenly.

What you need to work

In addition to what I will now list, in the process of work, you may need something that is not included in the list. So do not throw rotten tomatoes at the author if you have not indicated something. From materials you will need, of course, the balloon itself, as well as:

- steel pipes and corners;

- door hinges, note - also steel, no brass;

- if the design provides for a chimney, then a pipe with a bend at a right angle, with a diameter of 100 mm, will be required;

- nuts, bolts or studs for fastening the structure;

- heat-resistant paint and primer, emery, solvent, accessories in order to refine the appearance of the product (this is optional).

From instruments will definitely be needed:

- welding machine with electrodes;

- grinder, and disks for it will be needed both for cutting and for stripping;

- electric drill with drills for metal;

- roulette;

- center punch, chalk, marker for marking;

- brush for applying primer and / or paint;

- wrenches and pliers.

Which balloon is best for

In this case, it all depends on your gastronomic interests. If a lot of guests are planned, then it is better to take a capacity of 50 liters. Firstly, on such a grill, you can use skewers for the entire length, and secondly, arrange a fair amount of them.

If a compact, lightweight design is required, then it is better to opt for a 27 liter cylinder. General requirement - although the thickness of the walls of the cylinders can be 3 mm or more, if they are damaged by corrosion, look for something else under the brazier. Metal corroded by rust will not last long, especially in high temperature conditions.

Step by step description of the process

Conventionally, the course of work can be divided into four main stages:

- dismantling the valve and preparing the cylinder;

- marking and cutting of containers;

- production of the stand and assembly of the structure;

- decoration, priming and painting.

Now we will take a closer look at the progress of the process point by point.

How to dismantle the valve and what to do next

The valve is removed by means of an adjustable or gas wrench, or, even easier, a grinder with a cutting disc. Before starting to remove the valve, it must be completely unscrewed and the remaining gas released from the cylinder. On the side where the hole was formed in the place of the valve, you can weld a pipe with an elbow. It will turn out to be a pretty decent chimney.

Before starting cutting, you need to make sure that there is no more explosive and flammable substances. Even if the valve is already unscrewed and the pressure in the tank is the same as atmospheric, this is not an indicator at all. The fact is that a special additive - gasoline - which has a characteristic odor, is added to the gas that was once in the cylinder. It is also flammable, and if you do not get rid of it, trouble can happen. In addition, condensation is likely to remain in the container.

To drain the condensate, after dismantling the valve, turn the cylinder over and hold it for some time. And then, returning it to its usual upright position, fill it with water with a hose and leave it there for a couple of days. Directly before cutting, the water can be drained, but, in principle, this is not necessary - for the process its presence in the cylinder will not greatly affect, but it will completely protect against a possible explosion or fire.

Marking and cutting

Start by placing the cylinder horizontally on a level surface. As a guide when marking, you can use a weld along the wall of the cylinder. I will give as an example of the markup I liked, as they say, in a hurry. So fast, simple, reliable, and no need to fiddle with hinges.

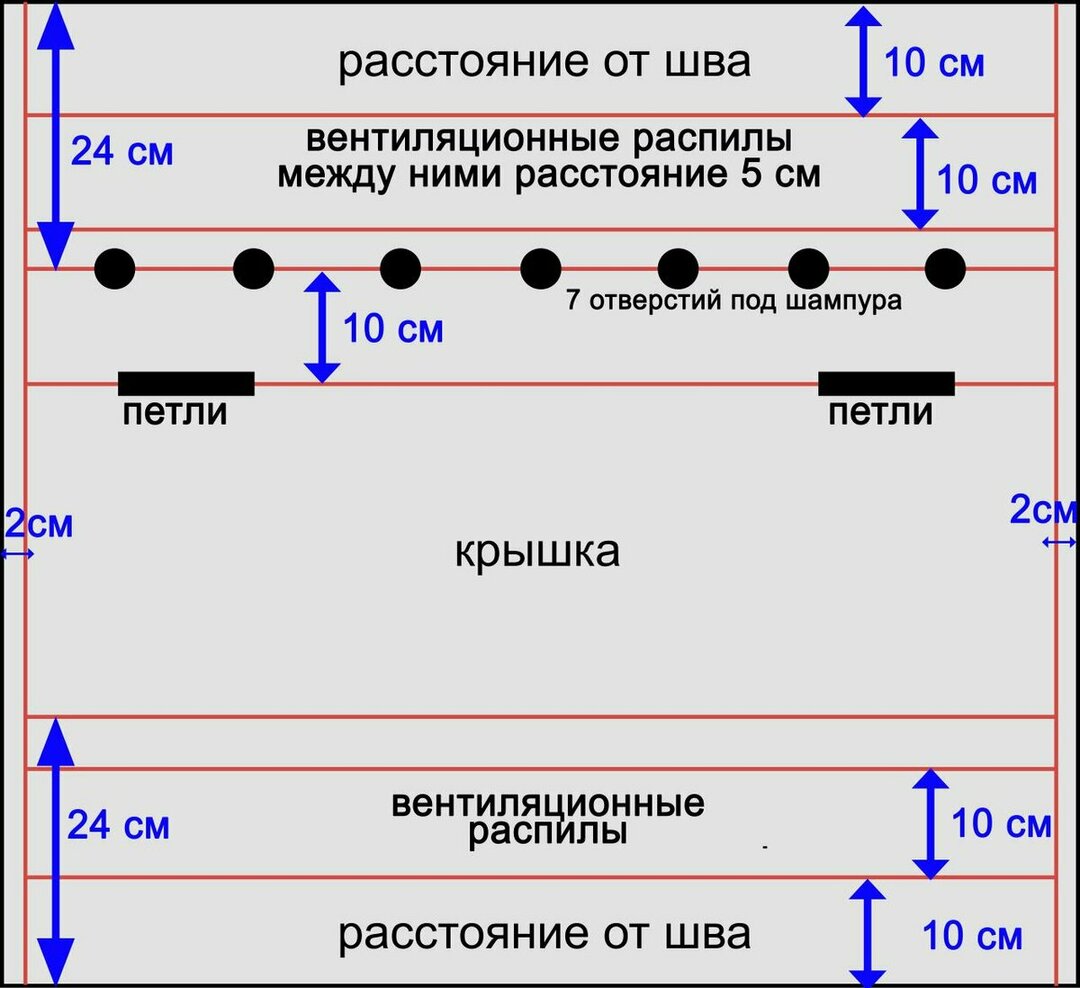

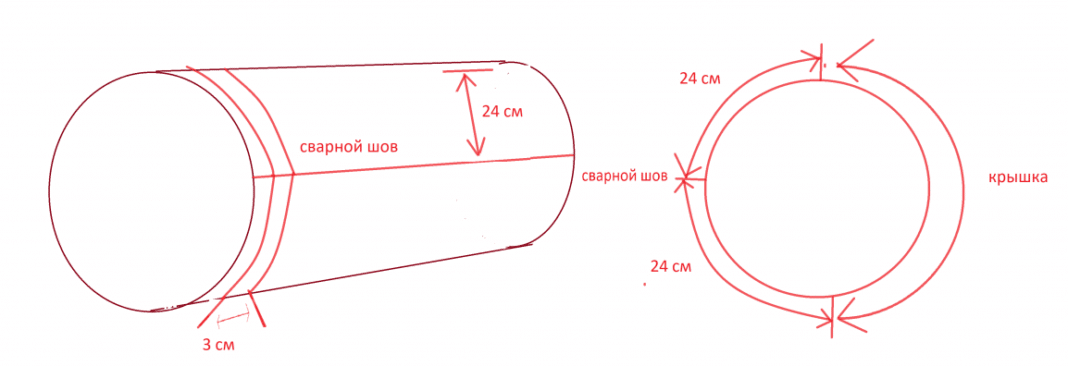

In this case, a fifty-liter balloon is used as a test subject. From the seam down and up on both sides, lay two parallel lines 240 mm long. Then we draw a kind of rectangle by connecting these two lines. You can use chalk or a marker as a marking tool. The outer diameter of the cylinder is 960 mm, that is, when marking, we clearly divided the container in half. Then, without further ado, we cut the container according to the markings with the help of a grinder.

On one of the sides of the resulting barbecue, about 8-10 centimeters from the top of the wall, after applying the markings, we drill holes for skewers at a distance of 8-10 cm from each other. Below the skewer holes, I recommend making parallel slots for air access. On the opposite side, opposite the holes, we make slots in the upper part of the wall.

Inside the structure, in addition to the slots for skewers, you can install a grate of the appropriate size and fry meat on it. It is not necessary to fasten the grill, let it be removable - used it, removed it, washed it properly.

Some are sophisticated - they make the structure closed, weld chimneys, equip two-chamber barbecues with cauldrons - yes, all this is real. But to make these delights, you need to have time, desire and the necessary skills. We are following the path of least resistance.

How to attach a brazier legs - in a good way

The design can be made collapsible or one-piece - it all depends on the owner's imagination. The main requirement is a user-friendly barbecue height - about a meter from the ground, plus or minus depending on the owner's height. For ease of transportation, it is better to make a collapsible structure.

The simplest version of the legs looks like this - four steel legs are welded to the barbecue body from a pipe or corner. If you want to be more sophisticated, make a metal frame with a stock for half a cylinder. It is made of two strips curved with an arc of the corresponding radius, welded to the frame from above, as shown in the photo.

The better to protect the brazier from corrosion

Before doing anything about the surface treatment, it must be thoroughly degreased, removed, if present, dirt, rust and scale. Then you can go in several ways:

- Use powder thermal paint, but for these purposes a special room and oven will be needed, since processing takes place at high temperatures.

- You can use organosilicon enamel, it is very heat-resistant - it can withstand temperatures of the order of six hundred degrees.

- Treat the case with a solution of sulfuric acid - this method is also called oxidation. After the end of the procedure, the body is boiled in water with laundry soap dissolved in it, after which it is kept for about an hour in a solution of sodium hydroxide.

That, in fact, is all - the grill is ready for use. On the Internet, you can find many more complex and bizarre schemes than the one we were talking about - if you like it, use it to your health.

Subscribe to our Social Networks