It is difficult to remember a tool that was used as widely as a grinder. If welding is to be done, then it must be taken with them. If manipulations with reinforcement are necessary, then this tool is also the first assistant here. The most important thing is not to forget that the device is a traumatic one, and safety precautions must be strictly observed. Mastering the operation of angle grinders must begin with learning how to remove and install the disc. Then you should learn how to turn the tool on and off, remove the protector. Further - to get acquainted with the peculiarities of working with different materials.

@ cuahangbosch.com

The content of the article

- How to work with a grinder: compliance with safety precautions

-

The basics of operating a grinder

- Removing and installing a disc

- How to turn the tool on and off

- Removing the defender

-

How to use the grinder correctly for different materials

- How to work with wood

- How to work with ceramics

- Metal cutting

- Working with glass

How to work with a grinder: compliance with safety precautions

LBM should be attributed to the most dangerous tools, since it not only works on electricity, but also does it at high speeds. Compliance with safety rules will help reduce the likelihood of injury:

- use of protective equipment;

- checking the reliability of fixing the protective casing;

- during operation, the grinder must be firmly held;

- absence of damage on the cutting discs;

- a protective shield should separate the circle from the person;

- before starting work, you should check the tool in idle mode;

- before starting, you must carefully inspect each of the nozzles;

- after finishing work, check the fixation of the disk;

- if the grinder has a speed controller, then its installation should be carried out in accordance with the recommendations of the instructions;

- cutting is carried out strictly at the recommended speed;

- so that there is no dust during the working process, the cutting site must be wetted;

- take breaks;

- put the tool down only after a complete stop;

- when the disk is jammed, you need to stop;

- when handling wood, you must be very careful;

- it is worth watching the cord so that it does not accidentally fall under the disc;

- circular saw blades cannot be used as they are designed for different working speeds.

The basics of operating a grinder

If you follow all the safety requirements, then the use of angle grinders is not so difficult, but you need to know the basic rules for using this tool.

Removing and installing a disc

In order to replace it, you need to press and hold the button that fixes the spindle. After that, using a wrench, you must unscrew the flange.

@ cuahangbosch.com

The disc can now be removed. When installing a new one, all actions are performed in the reverse order.

@ cuahangbosch.com

How to turn the tool on and off

Once the cut-off wheel is in place, the angle grinder can be used. On almost all models, the start button works in two positions:

- When pressed and held, the tool is activated. When it is released, the grinder stops.

@ cuahangbosch.com

- The button is pressed, after which it is fixed in this position. If you let her go, the work will continue.

@ cuahangbosch.com

It is better to fix the button during grinding. Even if the tool breaks free, nothing dangerous will happen. When cutting work is carried out, the button does not need to be fixed. In which case it will be much easier to stop the angle grinder.

Removing the defender

A protective cover is a necessary thing, especially if you want to cut some part. However, during grinding, it turns into a hindrance. In most of the angle grinders, you only need to unscrew a few screws to get rid of the casing. The example shows a grinder with a different method of removing the protective element.

@ cuahangbosch.com

It is equipped with a special fastener, which must be pulled towards you, after which the casing rotates inside the groove.

@ cuahangbosch.com

How to use the grinder correctly for different materials

LBM can handle a variety of materials. But each of them requires a special treatment. Which one exactly? We will try to figure it out with this.

How to work with wood

Oddly enough, but sometimes there is a need to saw not a metal part, but ordinary boards. For this case, there are special discs for the grinder, "decorated" on the sides with teeth. Use them carefully. You cannot put on a circular saw, since they are not designed to work at speeds of more than three thousand revolutions.

@ cuahangbosch.com

@ cuahangbosch.com

The Bulgarian is much more "resourceful". And the disk itself under it is made of steel, which is particularly fragile, so that it collapses at the first jamming.

How to work with ceramics

Cutting porcelain stoneware or ordinary tiles is only possible if a diamond-coated disc is available. It can be solid or segmented. This is usually referred to as dry cutting. If during operation it is not cooled with liquid, then every one and a half minutes it is necessary to interrupt the work. Solid discs do a good job even with paving slabs.

@ uiut.boltai.com

@ uiut.boltai.com

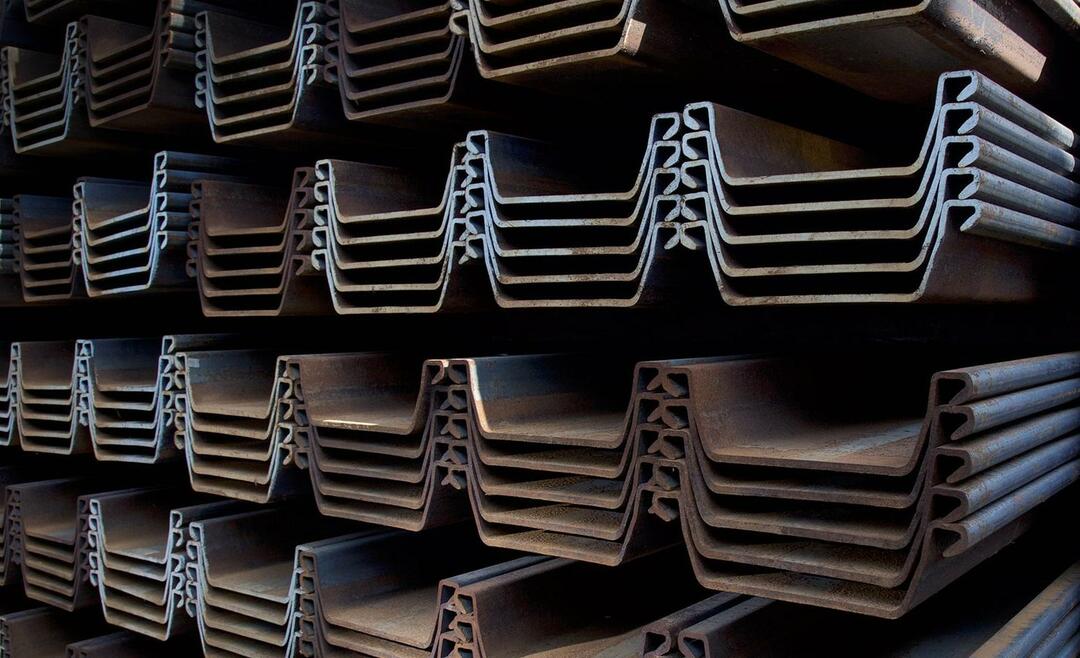

Metal cutting

It is for this that the grinder was invented. With its help, you can cut not only reinforcement, but even rails. But when working with metal, you need to be extremely careful.

@ uiut.boltai.com

@ uiut.boltai.com

@ uiut.boltai.com

@ uiut.boltai.com

You should be especially careful with the cutting disc. Care must be taken to ensure that it does not get stuck in the cut. It is better to hold the workpiece so that the cut piece is in the air. All kinds of corners, rails should be cut not in one pass, but separately cut each side.

If the workpiece is thick, cut only in a straight line. But in order to make a curly cut, first of all, you need to make a cut in a straight line in the form of a certain segment. The excess parts are then removed. Strong pressure on the angle grinder should be avoided.

@ uiut.boltai.com

Working with glass

Before you start cutting glass with a grinder, you should study a little all the characteristics of this material. For all its transparency and fragility, it has good strength characteristics. Moreover, it is not only a durable material, but also tough and good at resisting heat. Taking and cutting a bottle at home will not be very easy. Here, the appropriate tools are required, and the conditions are suitable.

@ uiut.boltai.com

The glass can only be cut with a grinder. But it is done very quickly. The only thing that is needed for this is to install a diamond-coated disc for concrete or granite on the grinder. During work, the incision site must be continuously watered with water. Since glass is a fairly strong material, a lot of heat will be generated when cutting. It negatively affects both the disc itself and the edges of the saw cut. Water, on the other hand, allows you to make the cut line more even, and the diamond spraying will remain for a long time.

Subscribe to our Social Networks