Duct fans are used to ensure the movement of air in the room. Simple devices are effective and used in residential, commercial, industrial buildings. But sometimes it is necessary to adjust the speed of the duct fan: to save energy, reduce the level of acoustic noise, adjust the flow rate of the intake and exhaust.

One way to change the degree of rotation of the blades of the apparatus is to use a step controller. Let's see how it works, where it is applied, what are the advantages and disadvantages of the device, what are the varieties. Let's get acquainted with some schemes for connecting such devices and the nuances associated with installation. All this will help you to choose and install the right regulator.

The content of the article:

- Feasibility of using the device

- The principle of operation of the step regulator

- Varieties and features of devices

- Connecting the controller to the hood

- How do I decrease or increase the speed?

- Noise reduction recommendations

- Conclusions and useful video on the topic

Feasibility of using the device

When the fan is constantly running at maximum speed, the resource of the device is quickly depleted. The power of the apparatus decreases and it fails. Most of the parts do not withstand such a load, they wear out, break. Installing the speed controller increases service life fan.

In addition to saving a working resource, the regulator also performs another important function - reduces noise from a working ventilation system.

In office premises with a large concentration of office equipment, the noise level reaches, and sometimes exceeds, the permissible noise levels. This is due to the fans running at full power. It is difficult to concentrate and work normally in such conditions.

Another good reason for installing a regulator is energy saving. The result of a decrease in the number of revolutions of the blades, a change in the total power of the device, is a decrease in energy consumption.

The principle of operation of the step regulator

The operation of the device is based on the application transformer, which is equipped with one winding, taps from the turns. The winding is branched. When connecting branches to the hood, an undervoltage is applied.

The step adjustment itself is carried out by changing the turns, which are connected to the fan input.

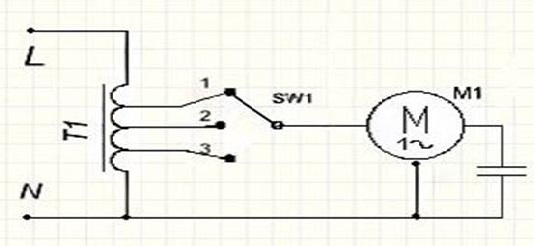

The simplest diagram shows that the 220 V supply network is connected to the T1 transformer coil with several branches. When the load is gradually connected to branches 1, 2, 3, only part of the voltage is supplied to M1

With decreasing voltage, the speed of rotation of the suction blades also decreases. At the output, we get an undistorted sinusoid, so when switching speeds, no interference occurs that affects other devices and the fan itself.

Other types of regulators use a different principle. IN electronic modules PWM action is based on varying the instantaneous power transmitted to the load. IN semiconductor devices the working function is laid on thyristors and triacs.

On the panel of the stepped device there is a knob and a scale, usually with five positions: 0 - off, 1 corresponds to the minimum speed, 5 indicates the maximum speed, 2, 3, 4 are intermediate values

The device is controlled by a step-by-step change in the supply voltage. The adjustment is done manually.

The controllers are mounted on the wall as switches, with their help it is easy to change the number of turns of the exhaust fan.

With a special switch, the fan is connected to the desired winding unit and the rotation speed of its blades decreases. At the same time, electricity consumption is reduced, which saves resource.

The advantages of the models include reliability, durability, high overload capacity. The disadvantages include the size of the control unit: this is not always convenient if the device needs to be placed in a confined space.

Two more disadvantages are the impossibility of smooth adjustment and the loss of energy for heating during adjustment. But when connecting temperature sensors, a timer, the process of changing the speeds is easy to automate.

Varieties and features of devices

Transformer regulators are ideal for situations where you need to manually control the speed of the suction blades. Their popularity is due to their moderate cost, as well as the highest reliability among their "colleagues".

Due to the wide power range of the manufactured devices, it is easy to select a model to be combined with fans from several W to several kW. But the models are not universal, they are matched to the types of hoods

Difference of step controllers from others types of regulators - the ability to work continuously for a long time at unmanned facilities.

The main technical characteristics of the devices:

- step voltage: 65-110-135-170-230 or 80-105-130-160-230 (figures differ depending on the model);

- single-phase and three-phase - 220 and 380 V, respectively;

- weight can be up to 30 kg (all devices are quite bulky);

- current frequency: 50-60 Hz;

- device protection class: 00, 20, 54 IP.

The cases of the devices are made of durable plastic and can withstand temperatures up to +40 degrees. Some groups of regulators belong to class B with a shutter speed reserve of up to 130 degrees.

There are devices with built-in protective devices that cut off the voltage supply to the fan if its thermal contacts are activated. Restart is performed by setting the handle to zero position for 10 sec.

Some models are equipped with equipment warning lamps and alarm indicators. There are also unique devices with the option of galvanic isolation from the network. These controllers can be used in healthcare facilities.

As additional options, the controller can have terminals for connecting and controlling external devices (for example, for air damper drives).

By design and type of serviced fans, controllers are divided into installed ones:

- on the walls;

- inside the walls;

- inside the ventilation unit;

- a separate special cabinet if the system is running "smart House".

Some models are DIN rail mounted, remote controlled.

If you need to regulate the speed on several fans, it is advisable to buy a multi-channel controller. There are models that can serve up to four or more devices simultaneously.

In the case of using one regulator for several duct fans, the total consumed current of the latter should not exceed the value of the rated current of the controller (plus a margin of 20-30%)

But, if the fans are located in different rooms, and the regulator is one, then the parameters on the hoods will be the same. In the case when you need a different microclimate in different rooms, it is more convenient to connect several controllers.

The large weight and dimensions of such devices, the complexity of external control are covered by their advantages in a stationary placement. The choice of a particular model depends on the technical features of the ventilation system.

Connecting the controller to the hood

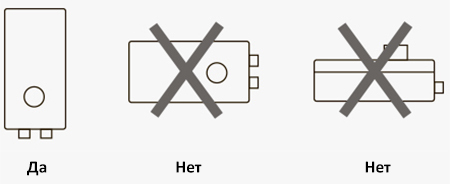

The device is mounted indoors. It is produced taking into account the recirculation of air masses to cool the internal circuits.

It is forbidden to place the regulator in an area with poor air convection, direct sunlight, above a heater. The working position of the device is strictly vertical, so the generated heat will be dissipated

To properly install the regulator, you must carefully read the instructions for the device.

Most models are designed for self-assembly by the user and do not require special knowledge.

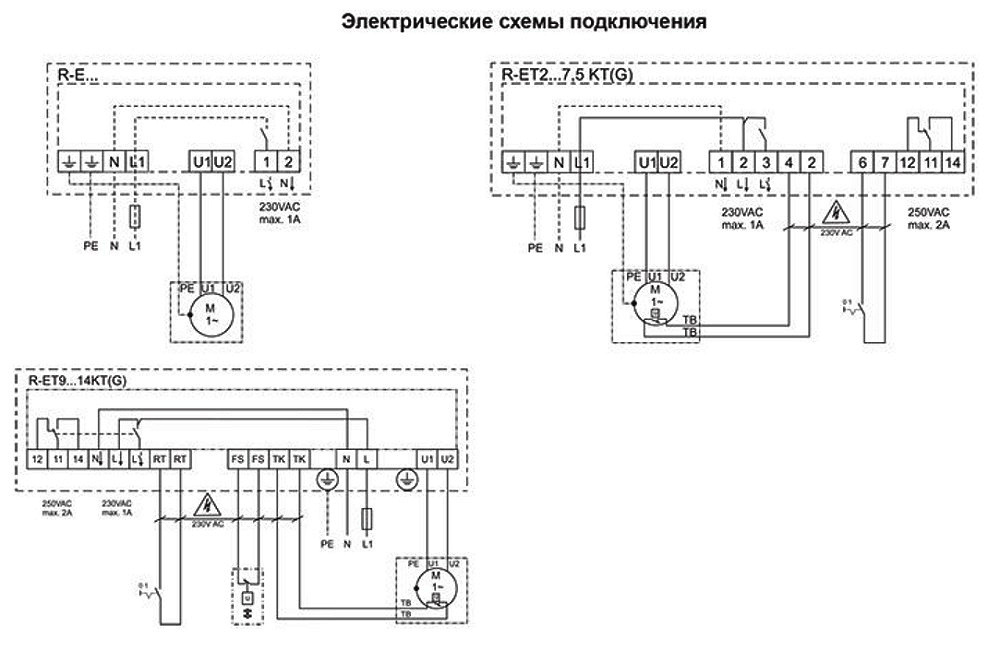

The contacts on the branded products are marked, and the delivery set includes recommendations for connecting, operating, and maintaining the device. Diagrams differ from device to device

Installation of wall and in-wall devices is carried out with screws and dowels, which are selected in accordance with the dimensions and weight of the device. Fasteners are usually supplied, as is the fan controller wiring diagram.

The general pattern and sequence of actions is as follows:

- The regulator is first mounted, then connected to a cable that supplies current to the fan.

- The wires are divided into "phase", "zero", "ground" and cut, connected to the input and output terminals. It is important not to mix them up and make all connections according to the instructions.

- The last step is to check the size of the cross-section of the supply cable and the connection for compliance with the maximum allowed voltage of the device.

The installation process for wall-mounted controls is the same as plug sockets, lighting switches. The old fan switch slot can be used to mount the controller. In this case, the switch must be dismantled.

When the control module and the regulator itself are housed in different housings, installation of the devices becomes more difficult. The control unit is powered from the electrical panel, and the executive module is connected via a low-current wire

If the controller has thermal contacts, it is recommended to connect it to motors with external thermal protection contacts connected to the TC terminals of the regulator. Such a scheme will reliably protect the main device.

When the thermal contacts open in case of overheating, the controller circuit is broken, the motor stops immediately and the emergency lamp comes on.

A motor without thermal contacts requires a separate thermal protection. Additionally, a jumper can be added to the circuit on the TC, but the rated current of the regulator must be 20% higher than the maximum motor current.

How do I decrease or increase the speed?

In hoods, thanks to the stepped fan speed control, it is possible to change the flow rate, which affects the overall air exchange. To control and use the method of changing the voltage.

The effectiveness of the device has been proven in practice. A simple and inexpensive device suitable for residential and public spaces. It can also perform additional functions.

For example, the O'Erre RG 5 AR model, in addition to the possibility of connecting reversible fans, has a module for connecting a light control. There is also a 2 A fuse in the case.

The speed is increased or decreased mechanically. The modules have a wheel for stepwise change of the exhaust motor speed.

Before connecting the power, it is necessary to check the wiring connections and the effectiveness of the grounding. It is not recommended to turn the power on or off often: continuous operation of the regulator ensures the optimum temperature and prevents the formation of condensation in the device case.

If the device does not have an automatic restart function and overheating occurs, eliminate the causes. The switch is set to the zero position for the cooling time of the engine, then the device is restarted.

Noise reduction recommendations

Often the desire to adjust the fan speed is associated with the increased noise level emitted by the appliance. The device should "sound" in the range of up to 55 dB. The normal level is 30-40 dB.

Silent units produce no more than 25 dB. Such designs have built-in gaskets, high-precision bearings that reduce vibration from the electric motor. And also selected the number of blades located at a certain angle

The regulator does not actually reduce the noise: at maximum speed, the fan emits the same sound as before. It works quieter when the revs are lowered.

In order to reduce the noise level from the hood even at maximum speed, you need to check the tightness of the attachment of the main device body to the wall, a special niche. Clearances can generate additional vibration.

These gaps are sealed with foam rubber or polyurethane. It is also useful to inspect the fasteners, which must be well tightened. Reduce noise and thin isolone substrate in a vibrating surface.

And the most effective way to reduce the noise of the hood is to choose silent duct fan.

Conclusions and useful video on the topic

How to connect the regulator to the fan. The example shows a thyristor controller, but the connection principle will help you understand the algorithm for working with a step device:

Features of connecting a duct fan through a speed controller + two more methods are discussed in the following video:

Stepped fan speed control makes the system less energy intensive, quieter, and precisely controlled. The controller ensures the safety of the main equipment, increases its service life. This is facilitated by safe starting, protection against short-circuit, current overload, overvoltage, open-phase mode.

The cost of purchasing the device pays off by saving money on the payment of the consumed energy. It is only important to select the parameters of the regulator for the fan being serviced. Most manufacturers have model matching tables that you can use when you buy it yourself. Consultation with the store manager does not fit either.

Do you have any questions about the topic of the article? Ask our experts and other site visitors - the feedback block is located below. Also here you can share your own experience and theoretical knowledge, participate in discussions.