It is very comfortable to live in a house where the temperature, humidity and oxygen concentration meet the established standards. To do this, you need to make a high-quality air exchange system. One of the conditions for its trouble-free operation is a properly assembled and installed ventilation duct on the roof, in which there are channels for air outflow.

The task of organizing air exchange is not new, therefore there are time-tested solutions, following which, you can perform all the work on installing the box yourself. To do this, you need to read the instructions we have written, prepare the tool and material, gather courage and start.

We have paid attention to some theoretical aspects of the placement of ventilation outlets and provided illustrated instructions on how to create a box. All stages are designed for a person who has initial skills in working with a conventional construction tool. No specific knowledge or skills are required.

The content of the article:

- Ventilation outlet placement rules

-

Stages of installation of the box

- Required materials and tools

- Roof hole cutting

- Forming a timber frame

- Warming of internal space

- Ventilation box waterproofing

- Waterproofing the base and sides

- Installing and fixing the umbrella

- Related videos and conclusions

Ventilation outlet placement rules

There are two standard ways to run ventilation pipes outside the home: through the wall and through the roof. In the second case, fragments of pipes located above the level of the roof are often placed inside a special box.

The ventilation box has two functions:

- Warming. Condensation forms when the air leaving the room is cooled. It begins to seep back through the ventilation system, and can also narrow or completely close the channel.

- Waterproofing. Violation of the integrity of the roof can lead to the ingress of water into the attic space. It is also necessary to ensure that the ventilation duct is protected from the direct ingress of precipitation in the form of rain or snow.

And also the box will serve as an excellent supporting structure for fastening the facing material and for providing an indentation from unstable building structures made of lumber.

The box on the roof of the house should look harmonious. Therefore, you need to think over its design in advance: colors and decorative elements.

If the house has planned or already implemented several ventilation outlets to the attic, then there are 3 options for how to bring them to the roof:

- For each channel, you can make your own box. This is the most costly method, however, in this case, it is possible to remove pipes without bends, which, with natural ventilation, increases traction.

- Bring all pipes side by side and bring them to the roof in one box. This reduces the amount of work on the roof, but increases the workload of the attic space.

- Make a unified system ventilation ducts with one outlet. This minimizes the size of the box, which will greatly simplify work on the roof, but can lead to problems typical for branched air exchange systems.

The use of a duct system with several points of air intake and one point of its removal must be well calculated in advance. It is necessary to properly arrange the supply ventilation and install check valves, otherwise the air flow can be reversed.

The hole in the roof must not damage the rafters, otherwise it will lead to the danger of redistribution of the load of the supporting structures. The lathing does not play such an important role, since it only holds the covering.

Since there can be a lot of ventilation pipes, you need to place them in the attic so that they take up little space.

You also need to carefully approach the issue of determining the location of the ventilation outlet so that it does not end up in the zone of wind back pressure.

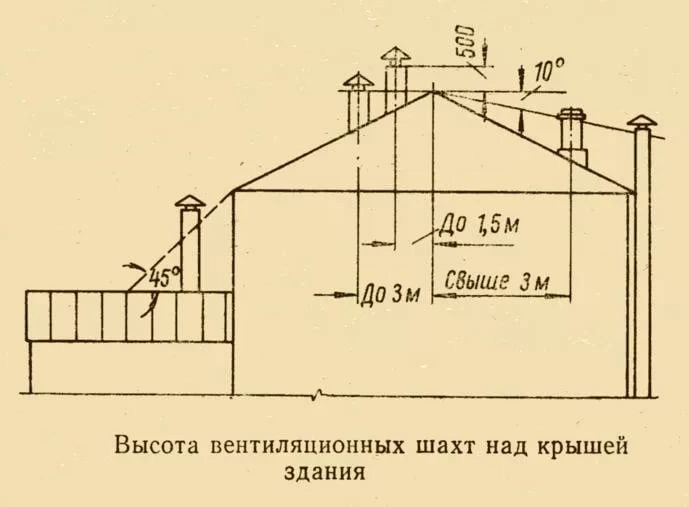

Failure to comply with the rule for the position of pipes relative to the roof elements, prescribed in cl. 6.6.12 SNiP 41-01-2003 "Heating, ventilation and air conditioning" can lead to a decrease in draft or its rollover, which will immediately negatively affect air exchange.

Using this scheme, you can determine the sufficient height of the ventilation outlets on the sloping roof of the house. If there are tall objects nearby, then the calculations will be more complicated.

Therefore, for a pitched roof, it is better to plan a place for the box closer to the ridge. This will reduce the height of the structure, which will simplify the work on its construction.

Stages of installation of the box

After the location has been chosen for passage of ventilation pipes through the roof, it is necessary to complete all the work in the attic (bring the pipe or pipes) and only then proceed with the construction of the box. This procedure is typical for private homes, so the different options have been well researched and a standard solution can be proposed to suit almost any situation.

Required materials and tools

Before deciding to make a ventilation box on the roof on your own, you need to understand that this event will last at least one daylight hours. Therefore, you need to know the weather forecast to be sure there is no rain or wind.

Any work on a pitched roof must be carried out in a safe manner. This requires:

- have a safety cable tied to the belt;

- put on the right shoes that do not slip or fly off your feet;

- install two ladders on the roof slope on the sides of the place where the box will eventually stand.

Neglect of safety rules can lead to the absence of a box on the roof in the near future, due to the installer getting into the trauma department of the hospital.

Ideally, a roof climb should look like this. But usually an ordinary staircase is placed on the roof with an attached corner that holds on to the ridge.

When carrying out work, the following tools will definitely be required:

- heavy hammer;

- screwdriver;

- saw on wood;

- scissors for metal;

- knife and scissors for soft materials and films;

- level;

- grinder (in the case of covering the roof with galvanized or metal tiles).

You also need to take care of a sufficient number of wood screws, construction tape, small nails and other consumables in advance.

Roof hole cutting

To accurately determine the position of the hole, it is necessary to drill 4 holes from the inside at the corners of the future box. Then, using a ruler, you need to draw a contour and start cutting it out.

If the coating is metal, then you need to use a grinder or metal scissors. You can remove roofing material or other “soft” material with any suitable tool: knife, scissors, jigsaw.

If it is possible to keep some of the crate boards without damage or with minor cuts, then this must be done

It is easier to remove a solid crate with a jigsaw, but you can also use an ordinary saw. Before doing this, it is better to determine from the inside where the nails and screws are attached, so as not to "catch" them.

Forming a timber frame

The frame can be made from edged boards 35 mm thick (there is no sense in greater thickness) or a bar 50 × 100 mm. The vertical posts should rest on the floor of the attic, and not be attached to the crate or rafters, since the box will have a large windage and under the influence of the wind force it can be demolished.

Above the roof, the frame is tied along the top and a reinforcement belt must be additionally installed at the roof level. It will also serve as the basis for attaching the skin.

After the construction of the frame, the pipes are extended from the attic to the top of the erected box. If the ventilation system is made of branded elements, then there is nothing complicated in this procedure.

If the pipes are not made of metal, then it is better to install them after assembling the frame, since plastic is easily shockable and can be broken during operation.

It is imperative to position the pipes exactly vertically, as well as to monitor their symmetrical arrangement inside the box. It is necessary to comply with the condition that from the pipe to the edge of the box there is at least 5 cm of space, which will be filled with insulation. And the top must be aligned, for which you need to use a level.

Warming of internal space

Before laying the insulation material, you need to hem the boards that close the box from below at the level of the attic ceiling. This must be done so that the insulation does not fall down.

Since it is impossible to put solid material in the box, there are two options left:

- freely deformable material such as mineral wool;

- bulk material such as perlite sand fraction 0.16 - 1.25 mm.

Expanded clay (insufficiently low thermal conductivity), foam plastic chips (coarse-grained), sawdust (can rot) are not suitable for this purpose.

Mineral wool should be laid very tightly, so that there are no cold bridges. Therefore, in units of volume, its consumption will be almost twice as much as the space of the box filled with insulation.

Mineral or basalt wool is easier to lay when the box is still in the form of a frame. It will be quite difficult to cram the material between the stiffeners and the wall.

Perlite is very “fluid”, therefore it perfectly fills all voids. But so that it does not leak out, the box will need to be laid from the inside with a dense fabric such as geotextile. You need to wear goggles and a mask when working with perlite, especially if there is wind on the roof. After filling from above, it is better to immediately put a layer of mineral wool or foam plastic with holes under the pipes, since perlite can swell.

Sheathe the frame with an OSB board or board, 1.0-1.5 mm thick. To save time, you may want to cut out the side walls in advance according to the dimensions calculated for the box. However, practice shows that this is not worth doing. When installing the frame, unforeseen deviations often occur, which will slightly change its dimensions.

After warming with mineral wool and installing the walls, the box looks like this. The insulation should be flush with the outlets of the ventilation pipes

If the walls of the ventilation box are assembled from several elements, then you need to remember that there is no special need for a tight fit of the joints. Therefore, you do not need to spend time on fitting.

Ventilation box waterproofing

One of the dangers for mineral wool insulation is water ingress and subsequent freezing. Therefore, it is necessary to carry out a vapor barrier.

For waterproofing, use a reinforced polyethylene film or polymer membrane. It is desirable to impose it in a whole piece.

In the center of the piece of waterproofing material, you need to cut a hole 2 cm smaller than the diameter of the pipe. Then, cuts must be made along the inner edge, no more than 1 cm deep. When put on a pipe, such an element will tightly close the gap between it and the plane of the slope.

From above, the film can be pressed down with foam by cutting holes for the pipe outlets. After that, the upper part of the box must be reinforced with mesh and cement.

It is better to cover polystyrene and mineral wool with cement. Otherwise, the birds will get to them and try to take them to their nests. In this case, insulation and steam and waterproofing will be violated. Before laying the covering, the area around the outlet of the ventilation pipe is covered with a waterproofing carpet.

If the pipes are below the level of the cement, then you need to add inserts. To avoid such a situation, it is better to immediately install the ventilation outlets with a margin of height (10-20 cm), since it is easier to cut off the excess than to deliver additional fragments.

Waterproofing the base and sides

When it rains or snows melt, streams of water flow down the roof. With special care, work must be carried out to prevent them from falling under the ventilation duct.

There is a rule that ensures that water does not enter when it flows freely along an inclined surface: the upper waterproof element must be pushed onto the lower one. According to this postulate, the structure of the waterproofing of the ventilation duct located on the roof is arranged.

The outer side of the rib, which will be facing down, must be smeared with liquid roofing material or double-sided bitumen tape should be glued to it. Then no spray will fall under it.

First, you need to nail the abutment strips to the base of the box. They look like corners with a side width of 5-7 cm. It is better to fix them not on nails or screws, but on bituminous mastic or liquid roofing material.

The strip, which will be on the side closest to the ridge, must be pushed under the roofing. Then the water will not flow under it, into the under-roof space and into the attic.

As waterproofing that protects the sides of the ventilation box, roofing tiles, soft tiles, rolled bitumen and bitumen-polymer roofing, polymer membrane, galvanized or any other durable material with water-repellent properties.

If it is not solid, then you must start fixing it from the bottom so that the upper parts are layered on the lower ones.

The ventilation shaft, equipped with a box, can be finished with any material, including flexible shingles and similar roll material. After waterproofing upholstery, the box will look like this

If you wish, you can install an additional visor in the middle, although if deflector for ventilation pipesgrouped in one shaft will have large protrusions, then there will be no sense in it.

The corners should be closed with a metal or plastic corner (with an edge width of 5-7 cm), which should be placed on top of the waterproofing. This is the simplest solution

If a soft material was used for cladding, then it is advisable to smear its joints with some kind of adhesive. For this, a liquid roofing material is suitable. This is necessary so that the strong wind does not ruin the waterproofing over time.

Installing and fixing the umbrella

There are 2 options: order a visor from manufacturers or make it yourself. As in the case of the sidewalls, there is no need to make an umbrella-deflector for the box in advance, since the dimensions of the constructed object may differ from the calculated ones, which will lead to the problem of joining the parts.

You can order a visor from companies involved in the creation of metal products. It is necessary to measure the outer perimeter of the upper part of the ventilation duct, choose the color and shape of the cover. Usually the production time takes 1-2 days. For this period, you need to cover the ventilation with a temporary cap, for example, made of plywood with roofing felt nailed over it.

You can make the simplest cap out of metal yourself. To do this, you will need corners, a sheet of metal with a thickness of 1.0-1.5 mm and the ability to work with welding

Also, the hood can be fixed on vertical bars that make up the frame of the entire ventilation duct. In this case, they should initially be 20-30 cm higher than the pipe outlet. The deflector can be made single-pitched from a wooden board covered with a galvanized sheet on top. With such a solution, it is not necessary to have a welding machine and the ability to work with it.

All wooden parts of the lid must be coated with antifungal impregnation or weather-resistant paint for external work, for example, grade PF-115. At the end of the installation, it is necessary to check that the installed visor does not stagger, otherwise the effect of the wind will gradually loosen the fasteners.

Related videos and conclusions

How to sheathe a brick chimney or ventilation duct. Part 1 - Installing Profiles:

Continuation of the previous video. Part 2 - insulation, metal sheathing and water drainage:

Two technical solutions for waterproofing the box, depending on its proximity to the ridge or cornice:

The main stages of installation of the ventilation duct are the same for any conditions: creating a hole, installing a reliable frame, insulation, waterproofing, sheathing, manufacturing and fixing the deflector.

The nuances of the work lie in the roof covering, as well as in the type of material from which the entire structure will be assembled. In most cases, you can do everything yourself, having initial skills in construction or repair.

Do you have any useful information on the topic of the article that is worth sharing with your site visitors? Do you want to tell how you equipped a ventilation shaft with a box at your own dacha or in a country house? Please write your comments in the block form below, ask questions, post pictures on the topic of the article.