The climatic technology of the Chinese company Gree has conquered the market for a long time. It is the world's largest air conditioner manufacturer. The variety of models produced in all market segments makes itself felt - to understand how they work blocking systems and how self-diagnosis mechanisms are arranged without a general idea of their typical errors impossible.

These air conditioners are not that complicated in comparison with equipment from manufacturers who claim to be high-tech, not mass. After all, the error codes of the Gree air conditioner are as unified as possible. You just need to know where, what to look for and how to interpret.

But it would not be superfluous to know whether it is worth paying money to the master immediately after the self-shutdown of the air conditioner, right? Fortunately for us and yours, the manufacturer made it so that in most cases the cause of the breakdown or how at least the "sick part" of Gree air conditioners can be installed by learning how to use all of them functions.

The content of the article:

- The most common Gree air conditioners

- General principles of diagnosis

- First steps in case of air conditioner malfunction

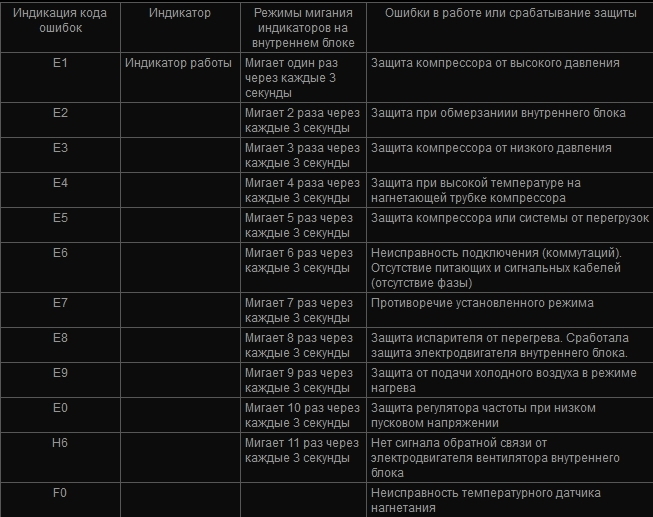

- Errors on the indicator of the air conditioner (E)

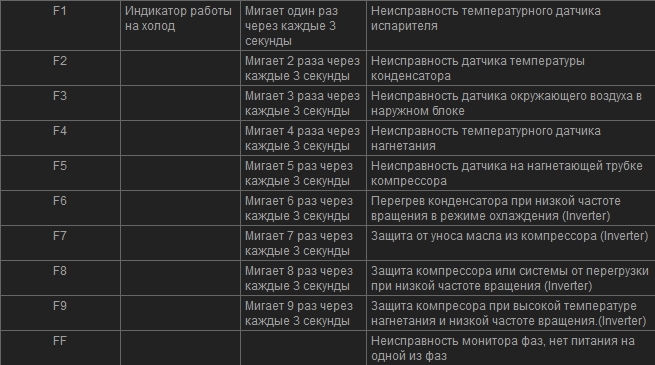

- Air conditioner cold indicator errors (F)

- Air conditioner heat indicator errors (H)

- Conclusions and useful video on the topic

The most common Gree air conditioners

This is not an idle question, since in most cases the average person is not well aware of the types of air conditioners. In addition, air conditioners of the same type often have several different names.

When they talk about household air conditioners, in most cases they mean two-block wall-mounted inverter split systems. Air conditioners without an inverter are already yesterday, in the world they are beginning to be banned for sale.

Gree inverter air conditioners are the world's most popular air conditioner model. HVAC equipment without an inverter is a thing of the past

To put it simply, split systems are such air conditioners, one “box” of which hangs outside the window, the other in the room. Gree also produces multisplit systems. Multisplit systems are when there is only one “box” outside the window, but inside the house there are several “boxes” and everything literally creates “the weather in the house”.

Have you looked closely? Did you see a box outside the window? Ok, that's enough, we continue diagnostics.

Gria air conditioners can use refrigerants for work:

- freon R22;

- freon R410a.

The chemical formula of the first substance is difluorochloromethane, the second is a mixture of pentafluoroethane and difluoromethane. It is not necessary to memorize the names, the main thing to remember is that the errors of two- and multi-unit air conditioners of the Gria brand, operating on different refrigerants, are displayed the same way.

General principles of diagnosis

The indicators of the sensors of the outdoor unit are displayed on the control panel and the indoor unit. Errors are displayed on the remote control, which are duplicated by the blinking of indicator lamps. Their location and purpose are easy to remember, there are only three of them.

Or you don't have to remember, on a number of models they are signed and their names are definitely in the instructions:

- Operating indicator (Running), its blinking is responsible for errors with letters E and H6.

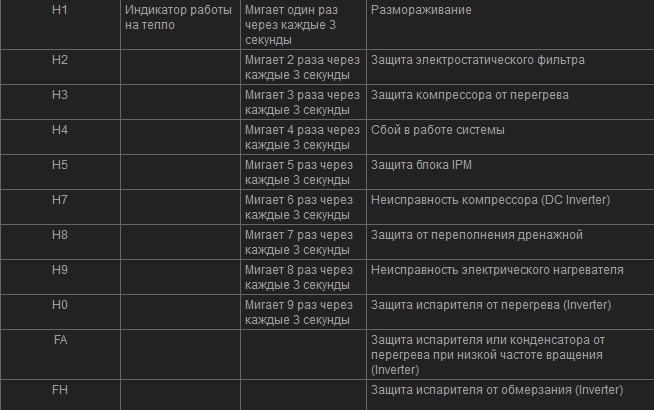

- Heat indicator (Heating mode), it "winks" if the air conditioner Gria issued errors with letters H0-H9, FA, FH.

- Cold indicator (Cooling mode), errors F0-F9, FF.

The lights flash in a certain sequence, thereby “giving out” this or that error. Also, errors are duplicated on the unit itself and on the control panel. So counting the number of winks that repeat every 3 seconds is optional. Moreover, there can be 9 or 11 of them.

A number of models of Gree air conditioners have little or no display. Therefore, the easiest way to diagnose is to use a remote control on which everything you need to know is written to determine the malfunction. Diagnostics is carried out based on the data of multiple sensors of the air conditioner.

First steps in case of air conditioner malfunction

And then something terrible happened. The indicators blinked, the “error” letter is displayed on the remote control, the air conditioner has turned off, can you already start to panic? There is no need to panic anyway. First you need to de-energize the inner panel of the air conditioner. If a multi-split system is installed in the house, then all of them must be de-energized.

After that, you need to wait 5 minutes and turn it back on. If, after turning on again, the same error is displayed again, then you should find out what you have to deal with. It is possible that the sensors are broken, and the system is in order. Or, perhaps, there are more than one error.

In this case, Gree air conditioners highlight the most potentially dangerous error. For greater ease of perception, it is better to conditionally divide the errors that arise according to the indicators responsible for them.

Errors on the indicator of the air conditioner (E)

Error E0 Gree air conditioner means insufficient starting voltage. That is, most likely, there is simply insufficient voltage “in the outlet”. This is potentially dangerous for an air conditioner, since prolonged exposure to inrush currents on its mains can cause overheating, which will “burn” the insulation of the wiring, and then the electrical appliance itself.

If the matter is “in the outlet”, then the problem is solved by purchasing a voltage stabilizer, which will bring the voltage to the required 220V.

But perhaps the point is in the wiring of the air conditioner itself. Therefore, if the mains voltage is 220V, but the air conditioner still gives an error E0, then you need to check it.

It is not so easy to connect both units of the split system to the mains. Incorrect connection will almost certainly cause errors and malfunctions.

Error E1 Is a shutdown to protect the compressor from too high pressure. Error E3 means the compressor is supplied with too low pressure.

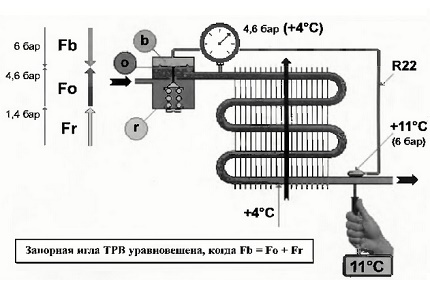

Sometimes to eliminate E1 rinse the air conditioner condenser well enough. If it is not blown enough, then this leads to an increase in the freon pressure. If the air conditioner has a water condenser, check the water intake. Another possible reason is an overabundance of freon itself or an unregulated thermostatic valve.

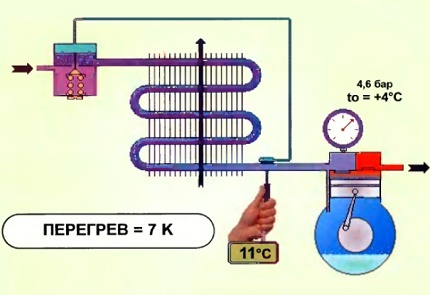

Just in case, you should immediately check the valve. It should at least be open. If everything is visually normal, then you will have to call the master to adjust the contour. It is unlikely that it will be possible to adjust the valve independently, moreover, without skills and a pressure gauge (it may also be necessary to adjust the discharge valve) and reload the freon according to the scales.

Most errors on the operation indicator are associated with the protection of the compressor - one of the most important components of the air conditioner

Too low pressure in the circuit can occur if the evaporator, fan or filter are dirty. That is, the algorithm of actions is exactly the same. First, the dirt is removed, and then the circuit is adjusted. You also need to check the tightness of the expansion of the joints. If traces of oil are visible on them, then the mixture is leaking.

Error E2 means that the indoor unit of the air conditioner may begin to freeze or is already freezing.

Using this error as an example, you can explain the general principle of diagnosing problems with a compressor (E1-E5):

- Some kind of sensor is triggered, warning of a problem.

- We remove contaminants that can cause temperature extremes. We check the fan impeller. Does the remote “give an error” anyway?

- Most likely, the problem is in the level of freon, loosely rolled copper pipes are leaking, the thermostatic valve or discharge valve is incorrectly adjusted.

If this is the case, then most likely you will have to call the master. Since we are talking either about initially wrong installation of the air conditioner (you will have to re-roll the pipes and refill the air conditioner with freon), or about more serious problems requiring replacement of components.

Problems are solved according to the same principle. E5 (activation of the compressor overload protection sensor) andE4 (triggering of the sensor to protect the compressor discharge tube from overheating).

Error E6 indicates that there is no phase, that is, it is necessary to reconnect the commutation. It is also necessary to check the commutation in case of an error. H6. By acting consistently and slowly, you can find a problem in an electrical circuit.

Error E7 – the contradiction of the specified modes is typical for multisplit systems. One block of a multisplit system is set to a mode that contradicts another block of the same system. The air conditioner, in simple terms, is confused.

Error E8 means that the indoor unit motor sensor is indicating overheating of the evaporator. Again, the thermostatic valve and discharge valve should be checked. If they are in order, then perhaps the evaporator simply runs out of freon. Or the evaporator tubes may be clogged.

Adjusting the circuit with a thermostatic valve and discharge valve is a delicate job that requires care and accuracy. The pressure gauge should be carefully read

Disable due to error E8 protects against excessively cold air in heating mode. Cold air can form a liquid which, if it enters the compressor, will almost certainly damage it.

And finally the error F0 means that the discharge sensor is broken. Most likely they are.

Errors on the air conditioner cold indicator (F)

Errors on the cold indicator indicate a malfunction of the sensors. But how can this be? After all, it was written above that almost all errors in the operation indicator can be associated with the fact that the sensor is not working correctly.

This is where the rule of priority of potentially more dangerous faults comes into play. A compressor out of order due to overheating or overload means the final breakdown of the air conditioner. A failed sensor is only a potential breakdown.

In addition, there are a lot of sensors on Gree air conditioners. Here are just a few of them:

- on the evaporator (error F1)

- on the capacitor (error F2)

- there is a sensor on the outdoor unit that measures indicators on the street (error F3)

- discharge temperature sensor (error F4)

- compressor discharge tube sensor (error F5), the very tube that can overheat and give an error E4.

If the sensors do not work as they should, then they need to be changed, there is no other way out. You can determine whether the temperature sensor is working properly or not using an ohmmeter or multimeter. They measure the resistance of the sensor. You will also need a thermometer. It measures the air temperature at the time of measurement.

Errors in the cold indicator more often indicate a malfunction of the indicator sensors. You can check their serviceability using an ohmmeter, thermometer and a table.

The nominal resistance at a specific temperature of Gree thermisters can be found in the detailed description of the model. In order to measure the resistance of the sensor, you need to remove it from the circuit, therefore it is better to adequately assess your knowledge of electrical engineering. If there are doubts about them, then it is better to call the master. He also calibrated the multimeter.

Error F6 means that the capacitor is overheating and the fan is running at low speed. In this case, the error F6 does not always mean that the fan is not working well. Perhaps it's a freon leak.

Error F7 protects the air conditioner from oil leakage by activating when it is carried away from the system. Errors F7 and F6 often occur almost at the same time for the same reason - the leakage of working fluid on the roller joints of copper pipes.

It is necessary to carefully inspect the connections, if there are traces of oil on them, you can begin to prepare at least for the rolling of all connections - the air conditioner was installed incorrectly.

Codes F8 and F9 talk about the threat compressor at low speed. F8 - the compressor is overloaded at a low speed, F9 - at high discharge temperatures and low speed. Anything can be the cause of compressor overload in this case. From commonplace dirt to a burned-out control board. Therefore, it is better to contact the service immediately.

Error FF indicates the lack of power on one of the phases, it is necessary to check the commutation.

Air conditioner heat indicator errors (H)

The most common nuisance is the code H1. She's the most easily fixable.

The air conditioner stopped supplying heat because it turned on the defrosting mode of the outdoor unit. The control sensor of the heat exchanger of the outdoor unit has worked and the automation has turned off the heat injection. It is fed to the outdoor unit, defrosting it. Unfreeze - everything will work. If not, then you need to check the health of the sensor and the heat exchanger.

Errors on the heat indicator can indicate a malfunction of the air conditioner circuit, as well as other problems of the external unit from the control board to a clogged drainage system.

Error H2 means that an electrostatic filter is at risk, the same one that collects dust and other particles circulating in the air. This filter can be cleaned. Or replace it with a new one. According to reviews, it is the filters of Gree air conditioners that are one of the weakest points. So it would be better to learn how to clean them beforehand.

To do this, you just need to remove the filter from the air conditioner, rinse in a detergent solution, rinse well under running water and dry thoroughly. And then insert it back.

An air conditioner with a dirty filter works louder, and noticeable arcing is also possible. So you can take action without waiting for an error. H2.

The electrostatic filter must be cleaned regularly. You can simply wash it under running water. This will help avoid big problems.

Error H3 protects the compressor from overheating. Overheating, like compressor overload, can occur due to oil, freon or freon and oil leakage. The first thing to check is the roll joints. Or maybe due to a malfunction of the fan or condenser.

If there are no traces of oil on the connections, the fan is working normally, and the external unit itself is clean, then it is necessary calibrate the circuit using the same discharge valve, thermostatic valve and pressure gauge.

Error H4 means a malfunction. If the air conditioner does not work after restarting, the problem is either in the control board or in improper installation.

Code H5 means there is a problem with the outdoor unit IPM board. If the board is out of order, it needs to be replaced.

Letter H7 means that compressor malfunction indicates energy saving inverter (DC Inverter). It is he who is responsible for turning the compressor on and off in inverter split systems. Constant switching on and off will sooner or later affect the operation of the compressor. Error H7 rarely happens for reasons that you can fix yourself.

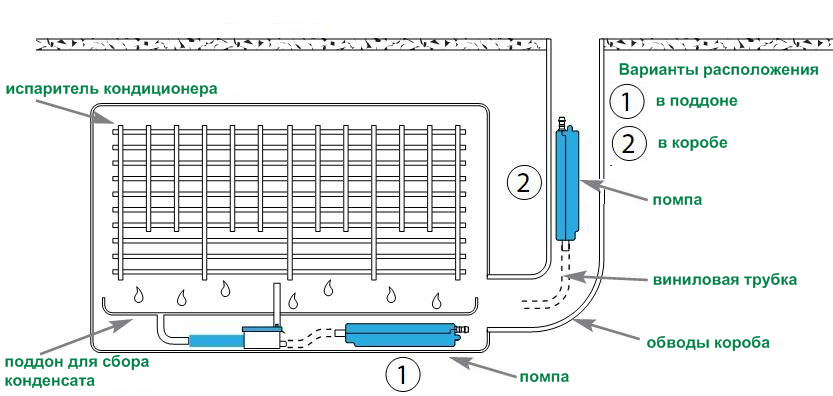

Error H8 means that the automation considers the drainage system to be overfilled with condensate. The external drainage system needs to be checked. If it is clogged, clean it.

The condensate drain system is one of the simplest and most intuitive air conditioning systems. You can clean it yourself

H9 - the problem is in the electric heater. First you need to check if it works. If it does not work, then the reason may be an open circuit. Or the heater has burned out.

Problems H0 and FH unambiguously mean the activation of the temperature sensor on the evaporator (H0) or on the evaporator and condenser at a low speed. It is necessary to check the refrigerant circuit and the refrigerant level in the circuit as in the case of errors E7 and E8. The reasons are exactly the same, only the inverter sensors indicated them.

A circuit with a thermostatic expansion valve is one of the basic systems that ensure the operation of an air conditioner. The performance and durability of the climatic equipment depend on its action.

Error under the letter FH means that the evaporator may freeze up. A working air conditioner can fix the problem on its own. If necessary, it must be cleaned. Also, the evaporator may freeze due to a freon leak or a failure in the valve and circuit valve settings.

Conclusions and useful video on the topic

Instructions for eliminating the E4 error - filling with freon by scales and rolling helped to solve the problem:

As you can easily see, some breakdowns can be noticed by all three indicators. The only question is which indicator will notice the breakdown earlier. Therefore, before trying to correct mistakes on your own, you need to understand in general terms how the internal and external units of the air conditioner are arranged, the principle of operation of the circuit and the principle of connecting the air conditioner to electrical network.

After that, many questions will disappear by themselves. It will be enough to look at the table and remember what exactly this or that letter means. And then it is already to act according to the circumstances.