If you properly prepare a solution for plastering walls, it forms a strong layer on the surface, able to withstand mechanical stress, excessive humidity in the room and temperature changes outside.

The content of the article:

- Composition and features

- Proportions for cement-sand plaster

- Additional components for plaster

- Preparing walls before plastering

-

Number of layers

- Splashing

- Priming

- Nakryvka

- How long does cement-sand plaster dry

Composition and features

Before preparing a cement mortar for plastering walls, you should understand the recipe for the mixture. It contains three components - cement, sand and water, they are also an astringent, filler and solvent, respectively.

In order for the quality of the leveling material to comply with the standards, you must pay attention to the following:

- For wall plastering, cement grades from M300 to M600 are used. The higher the brand, the more expensive the material. But each of the options is applied taking into account the purpose of the plaster. For example, M300 cement is used if it is necessary to level the walls inside dry rooms. M600 - for wet rooms.

- Any type of sand can be used as a filler, for example, river or quarry sand. The main thing is that the material is as clean as possible, that is, with a minimum amount of clay inclusions. Clay reduces the characteristics of the plaster. Used sand fraction 20-40 mm. Before adding to the mixture, it must be sieved to remove debris and large granules.

- There is only one requirement for water - it must be free of solid inclusions.

Cement-sand mortar for plastering walls is divided according to quality characteristics into three types:

- Simple. It is used when it is necessary to plaster walls in office-type premises where high quality finishes are not required.

- Superior - at the objects of a residential, office or industrial complex.

- High quality. It is a finish, ready, for example, for painting. Such a composition is suitable for covering walls in houses, hotels, museums and other buildings similar to them.

Today, more and more additional requirements are imposed on plaster mortar. They mainly relate to the technical and operational characteristics of the mixture. For example, increased moisture resistance, fast solidification, resistance to harmful microorganisms (mold, fungus), increased plasticity for ease of operation.

Therefore, different materials are added to the solution at the stage of mixing:

- Alabaster, aka plaster of paris. Its purpose is to make the solution quick-setting, that is, the time of solidification of the mass is reduced. It is used to level slopes, during the installation of electrical wiring, to seal large defects in wall surfaces. Usually, alabaster is added to a solution of cement and sand. Quantity - 25% of the total volume or mass of the cement-sand mixture.

- Gypsum is the same alabaster, only of a smaller fraction, hence its high quality. Plus - not lightning-fast drying, which makes the solution more plastic. Use this mixture for finishing corners, ceilings and hard-to-reach places. It is added to a solution of cement and sand in the form of an aqueous slurry.

- Lime. With the addition of this building material, cement plaster acquires a large number of positive properties - bactericidal, strength, moisture resistant and others. This mixture will not crack on the wall. No lime is added in its pure form. Lime milk is added to the solution - this is mixing it with water in a ratio of 1: 2.

- PVA glue. Firstly, very little is added - 5% of the total. Secondly, with its introduction, the plaster acquires additional qualities - low cracking, high adhesion properties, increased strength of the applied layer.

- Liquid soap. This material has only one purpose - to make the plaster plastic plastic. It is added in the amount of 3% of the total volume of the mixture.

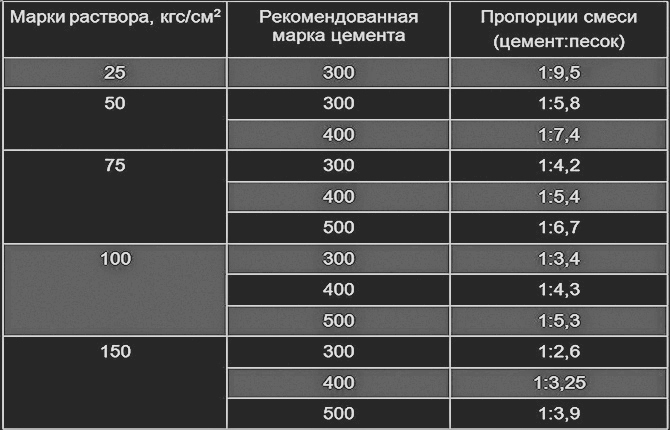

Proportions for cement-sand plaster

There is a classic recipe in which the ratio of cement and sand is 1: 3. That is, one part binder, three parts filler. In this case, a certain brand of the plaster mortar itself is obtained, but it depends precisely on the brand of cement:

- if the binder has a M300 brand, then the solution brand will be M100;

- if M500, then the mixture will be M200.

That is, the higher the binder grade, the higher the plaster grade.

But you can get a brand of M100 mortar from M500 cement. For this, the recipe changes, that is, the ratio of the components introduced. It is 1: 5, that is, one part of cement, five - sand. In this way, the desired brand of mixture is selected.

One gets the impression that by changing the recipe, you can reduce the cost of the final product. But in order to add more cheap sand, you have to purchase an expensive brand of cement. So it is impossible to save on this.

The recipe for the preparation of various brands of mortar, depending on the cement used

It is not difficult to mix the solution for plastering the walls yourself. The main thing is to prepare the amount that will be consumed within an hour. Exceeding this time leads to solidification of the mass, which can no longer be used.

Plaster preparation procedure:

- cement and sand are poured into the container, mixed with a trowel or shovel;

- water is poured, kneading is carried out using a construction mixer;

- the resulting material is checked for readiness - the consistency should be creamy. A trowel is carried out along its surface, from which a groove should remain.

How to prepare a solution for plastering walls can be seen in the video.

Additional components for plaster

Often, other building materials are added to the plaster solution, with the help of which the surface characteristics and decorativeness of the outer layer are enhanced. For example, add:

- Coarse quartz sand. The plaster becomes waterproof. It resists well the negative effects of acids and alkalis. It is characterized by high vapor permeability, that is, it allows air to pass through itself, which is important for creating an optimal microclimate inside the rooms.

- Fine barite. The wall becomes a shield against radiation penetration. It is with this kind of plaster that I decorate the walls in X-ray rooms.

- Expanded polystyrene crumb. This type of plaster forms an insulating layer on the wall.

- Metal shavings. The wall becomes impact-resistant and beautiful at the same time.

- Marble chips. Makes the wall strong, but additionally brings other useful qualities to the plaster composition - moisture resistance, the ability to withstand temperature extremes well. Such a solution applied to external walls is not afraid of natural stress. The aesthetic appearance is also a feature of marble plaster.

- Crushed mica. The plaster layer protects the building from UV radiation.

- Acrylic, resin (epoxy, polyurethane). The plaster acquires high waterproofing qualities.

- Liquid glass, stone flour, quartzite. Make the solution acid-proof. Such plasters are used in the decoration of the walls of buildings in the chemical industry.

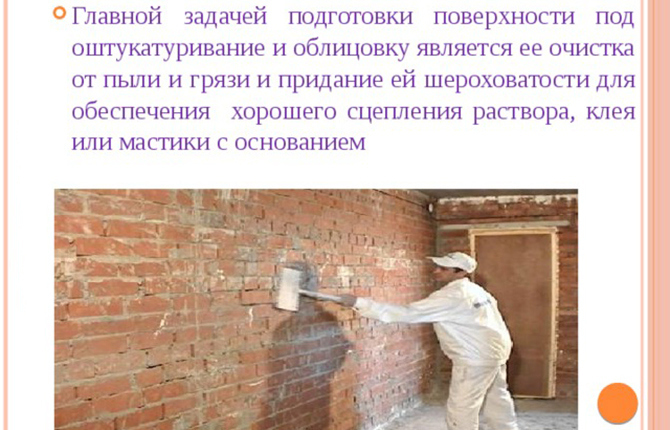

Preparing walls before plastering

Preparing the walls takes a lot of time. This must be done carefully and strictly according to the following recommendations:

- All old finishes are removed. For this, well-known methods are used with the use of construction tools. For example, paint is cleaned with spatulas. If some areas cannot be removed, a grinder is used with a metal brush attached to its shaft.

- Metal materials protruding from the wall (fittings, embedded) are cut flush with a grinder, the remaining ends are treated with anti-corrosion compounds.

- The entire surface of the wall is dust-free. A construction vacuum cleaner is often used.

- A primer is applied, which increases the adhesion properties of the wall.

The primer is an important material in the process of preparing walls for plastering. It is presented on the market in three types:

- Deep penetration, it is polymer. Penetrates into the upper layers of the walls, where it polymerizes, reinforcing the material. Used to treat walls made of loose material, exfoliated, if the surfaces were covered with lime plaster.

- Adhesive primer. This is a composition to which quartz sand is added. It increases the adhesion of the wall to other materials.

- Acrylic, it is also universal. It can handle any surface except wood and metal. Such a primer fights well against fungi and mold.

The next stage of preparation is the installation of beacons on the wall. For this, ready-made aluminum or galvanized steel profiles are used. For wooden walls, ordinary slats are used.

The installation process for beacons is simple:

- Check the walls for unevenness using a plumb line.

- One profile is installed strictly vertically near the corner between two adjacent walls. Fastening is carried out using plaster.

- In the same way, the second profile is mounted at the opposite corner.

- Two fishing lines are pulled between the profiles: one 20 cm below the ceiling, the second 20 cm above the floor.

- Intermediate beacons are installed along the stretched lines between the two profiles. The distance between them is less than the length of the rule. This instrument should lie at its ends on two adjacent beacons.

Number of layers

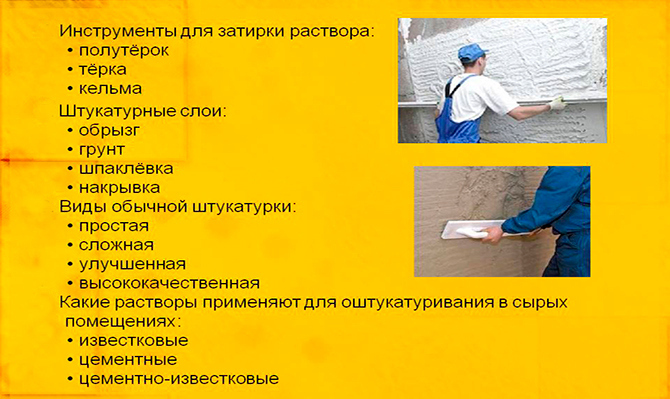

Plastering of walls is carried out in three stages, in each of which a solution of a certain consistency is used. And each such mixture has its own name - spray, soil and cover.

Splashing

It is a creamy solution, liquidish.

Its purpose:

- to form a layer with high adhesion characteristics on the wall;

- close large defects in the wall, for example, seams between bricks, wide cracks, chips, grooves.

Prepare a solution with plenty of water. It is applied with a thickness of 2-5 mm. The process is carried out with effort. That is, the mixture is collected in a trowel and pounced with force on the processed plane. The movements must be sharp so that the speed of the throw creates pressure on the defects, which would be completely filled with the material.

Priming

This is the thickest layer - up to 5 cm. The plaster itself is a dense solution with a low water content. It was him align with beacons. That is, the space between the profiles is filled with the mixture and stretched with the rule from the bottom up, making wave-like movements from side to side.

If the difference in the plane of the wall is large, then the soil is applied in several layers. But the leveling of the surface is usually carried out only after the entire space is filled with the material.

Lighthouses are removed after the soil has dried. The grooves remaining in their place are filled with plaster mortar.

Nakryvka

This layer can be attributed to the final formation of the plastered wall. After applying it, the surface becomes as flat and smooth as possible. Therefore, the mixture is made practically liquid.

Apply the solution with a trowel, and with it, level the surface in circular movements, distributing the material evenly. The important thing here is to properly prepare the mixture. Application thickness - no more than 2 mm.

Each previous layer must be well dried before applying the next one. The mixture applied must acquire a certain strength in order to withstand the weight of the next layer to be applied.

How long does cement-sand plaster dry

In order for the quality of the plaster to be high, it is necessary to adhere to the requirements of SNiP. One of them says - it is necessary to work with plaster mixtures at a temperature of 18-20 ° C and a humidity of no more than 70%. These are optimal conditions.

Also in the rules there are standards for the drying of layers applied with a thickness of 2 mm. They are determined by the materials used to construct the building.

| Wall view | Drying time of cement plaster, h |

| Brick, concrete | 24 |

| Aerated concrete, expanded clay concrete (dry) | 6 |

| Aerated concrete, expanded clay concrete (wet) | 24-48 |

| Plasterboard | 9 |

| Wooden | 9 |

Since the plaster is made on the basis of cement, it gains its brand strength only after 28 days. The drying process can be accelerated if all work is carried out in the summer. Do not use artificial drying with heat guns, dehumidifiers and other devices. This will lead to cracking of the applied layer.

The quality of the plaster applied not to the wall will always be high, if you strictly adhere to all the above rules for the preparation of the solution, the installation of beacons, the preparation of the walls and the application of the plaster.

If you liked the article, or you are not satisfied with something, please let us know in the comments. Save useful information in bookmarks, repost on social networks.

Mixing mortar for plaster in the video.

Related article: Decorative plaster for concrete.

Sources:

- https://kvartirnyj-remont.com/shtukaturka-iz-cementa-i-peska.html

- https://dekorshtukaturka.ru/oshtukaturivanie/rastvor-dlya-shtukaturki

- https://m-strana.ru/articles/kak-prigotovit-rastvor-dlya-shtukaturki-sten-iz-tsementa-i-peska