Are you going to sheathe walls or ceiling with plasterboard? Perhaps you have plans for the construction of complex shapes from this versatile material? In any case, you will not do with only whole sheets, so it is important to know how to cut drywall at home and what is needed for this.

Drywall is an easy-to-use material; it can be used to build almost any structure. Even a beginner can open it without a special tool. Professionals have their own methods and tools to make cutting large quantities of sheets quick, easy and accurate.

In this article, we will consider the whole variety of tools, both for the home craftsman and for real pros. We will tell you how to cut flat strips of drywall, make a hole in it, give a sheet or cuts any shape. As a bonus, we'll show you how easy it is to clean the house after this dusty activity.

The content of the article:

-

Choosing the right tool

- To mark the cutout

- Hand sawing and cutting tool

- Drywall Cutting Power Tool

- How to align the cut?

-

Drywall cutting methods

- Method number 1 - cutting in a straight line

- Method number 2 - rectangular and square holes

- Method number 3 - round holes

- Method number 4 - cutting without tools

- Method number 5 - curly cutting

- How to remove gypsum dust?

- Conclusions and useful video on the topic

Choosing the right tool

Drywall combines high bearing capacity with ease of processing: you can cut and saw it with almost anything.

So that you can choose the best option, we will describe the main devices, their advantages and disadvantages.

To mark the cutout

It is best to mark the cutting line on the sheet with a simple pencil - clerical, or a thicker construction pencil.

A marker or pen can show through a thin layer of putty. It is better to use them only for marking on the back of the sheet.

Measure the required dimensions, the distance from the edge of the sheet to the cutout is most convenient with a tape measure.

To keep the lines straight, draw them under a rule or a long ruler. Use a square for perpendicular intersections, and a compass for round holes.

Hand sawing and cutting tool

Stationery or construction knife - the simplest, most affordable and popular cutting tool drywall. It is used by both beginners and professionals. The knife cuts the cardboard and the plaster layer breaks.

The method is simple, it creates a minimum of dust, the edges of the cardboard are smooth. Among the shortcomings - the uneven edge of the gypsum layer sometimes requires improvement, it will not be possible to make a round hole or cut a sheet fixed on the wall.

With a tape measure, you can measure on the wall and cut off a strip or circle from the sheet, bypassing the marking stage. For a straight cut, training is required

An even cut is usually made with a knife, that is, the sheet can be reduced or dissolved into strips. It will be problematic to perform more complex shapes with this tool, but it is possible.

Hacksaw - a universal option, it cuts through the sheet, can be used for holes and lines of any shape, before or after installation of drywall. At the same time, it is inexpensive and is available in almost every home. It is better to choose a hacksaw for metal - its small teeth do not tear the cardboard, and the thin blade bends at the curves.

Specialized drywall hacksaw "Fox" has a pointed nose for driving into the leaf or teeth on both sides of the blade.

Circular knife cutters are able to cut through cardboard from both sides of the sheet at once absolutely symmetrically, in one pass. It is quick and convenient, but not everyone has such a tool. They are used for cutting only up to the stage of material installation. U-shaped models with a parallel stop will help to cut the strip, but its width is limited by the maximum length of the tool.

Magnetic cutters consist of two separate soles that are magnetically attracted to each other through the sheet. It will take some training or some additional tools to guide the magnetic disc cutter across drywall exactly along the line of the markings.

The wide blade saw on drywall is only used for straight cuts. It turns out quickly, smoothly and practically without dust

You will need a hammer if you need to make a hole in the drywall, and there is nothing other than a knife. The result is not very neat, but sometimes that is enough.

Drywall Cutting Power Tool

From a universal power tool, drywall is cut with a jigsaw with a blade for metal or a hand circular with a disk for wood. You can cut several sheets at the same time, which significantly speeds up the work. For straight stripes, it is convenient to use a parallel stop - it is usually included in the tool kit.

The cut is smooth, but at high speed or with a dull canvas, the cardboard can be undermined, resulting in a fringe. The main disadvantage of these tools is that a lot of gypsum dust is created: it is hard to breathe and to clean up later in the house.

Also, it is not always convenient to arrange a large sheet of drywall so that it does not break, and there was space for the saw to move freely under the cut.

A circular saw - the only tool that can easily cope not only with drywall, but also with a profile. This will help out if you need to cut a hole that was not foreseen during the plating and now it falls on the profile.

Reciprocating saw - a rarer tool, very similar to a jigsaw, but capable of sawing practically without support: the sheet may not be fixed, stand upright or at an angle. The tool is cordless, independent of sockets, but the cut is less accurate.

A jigsaw is usually used to cut drywall before installation, and a reciprocating saw is often used after fixing the sheet.

Drill or screwdriver with various attachments are used for round cutouts, as well as for a starting hole for a hacksaw blade.

Drill bit, often used in the installation of wooden doors or windows, is suitable for small diameter holes. The maximum pen size is 60mm, but often up to 25 - 35mm are used - for example, for removing wiring.

Crown - metal cylinder with a pilot drill in the center. Used for round holes up to 10cm in diameter.

Most often, cutouts made with a crown are needed for recessed lights, sockets and switches. They can be cut even after the completion of the renovation.

The ballerina nozzle will help you cut a hole up to 40cm in diameter - for example, for a fan. Its base is a crosspiece, on the shoulders of which the blades are fixed. By moving the knives, you can change the hole diameter.

How to align the cut?

The edge of the gypsum plasterboard, mounted end-to-end or forming a corner, is usually covered with putty through a reinforcing mesh or corner. This means that any irregularities in the cut and gaps will be hidden, additional processing is not needed.

If there are bulges on the cut that interfere with installation, or for some reason the protrusion will be covered with putty without using a corner, the edge of the sheet is leveled with such a tool:

- roughing plane, rasp;

- sandpaper;

- clerical or construction knife;

- file.

Choose a tool depending on the shape of the cut and what is at hand.

Drywall cutting methods

To cut drywall exactly, exactly, without spoiling a single sheet, you need to know some rules.

In this section, we'll look at how to use the above tool on a case-by-case basis.

Method number 1 - cutting in a straight line

Such a cut is necessary in any repair: after most of the area is sewn up with whole sheets, it is inevitable you will need stripes and small rectangles to fill in the gaps, as well as create decorative designs.

You can make a cabinet, shelves, a false fireplace, steps, columns and many other decorative and functional structures from drywall. The more complex the shape, the more you need to cut

Most often, strips of drywall are cut with a knife. The procedure is as follows:

- Measure the required width on the wall.

- Set aside this distance on a sheet of drywall, put marks on its back.

- Apply a rule by marks, draw a line.

- Pressing the rule tightly, cut the cardboard and the top layer of gypsum along it. Lead the knife with pressure, several times.

- Break the sheet along the cut line so that the cut opens. If the material lies on a table or other elevation, move it with a cut to the edge of the table; if the sheet is standing, fold it by pulling the edges with your hands, knocking your knee on the whole, uncut side.

- Cut a layer of cardboard from the second, front side, along the resulting fold line.

- If necessary, trim the edge of the plaster layer with a knife or plane.

Using specialized disc cutters, you can cut 2 layers of cardboard at once: all that remains is to break the sheet.

If you combine them with a parallel emphasis, then you also save time on marking.

In this way, you can cut elements of any size, but only rectangular. The error in the width of the strips will be 1 - 2 mm, which in most cases is not critical.

If you need to cut an arched gypsum board reinforced with fiberglass, or cut several sheets at once, use a jigsaw or a hand-held circular saw. It also makes sense to cut with a jigsaw on the rip fence if high precision is required.

In other cases, the choice of hand or power tools is a matter of taste. The speed of work with a certain skill with a knife can be even higher, moreover, it does not raise a cloud of dust.

When cutting with a jigsaw, select the blade for metal and guide the tool slowly. It is better to draw the markings with a marker so that it can be seen through the dust, but only on the back of the sheet.

A hand saw or a saw for long, even cuts is rarely used - this is not rational.

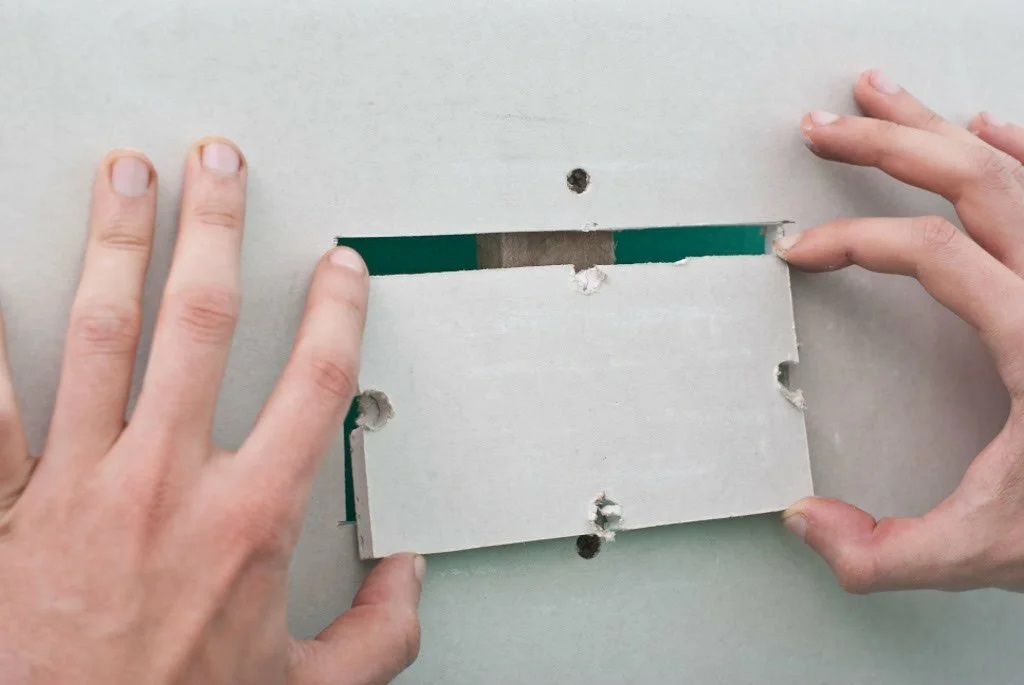

Method number 2 - rectangular and square holes

The easiest way is to cut a rectangle or square for communications or an inspection hatch at the edge of the sheet.

For this:

- Apply the markings.

- Saw through the edges perpendicular to the edge with a hand saw or jigsaw.

- Cut the cardboard along the remaining edge with a knife.

- Hit the resulting door, breaking it.

- Cut through the second layer of cardboard.

If the hatch falls in the middle of the sheet, it is convenient to cut it out after fixing the sheet to the wall. To immerse an ordinary hacksaw in the sheet, drill one or more holes in a row.

When using a conventional hacksaw for metal, with a blunt nose, you first need to drill holes in each face of the future cut

It is convenient to use a plasterboard hacksaw - a fox. Its sharp nose is driven into the sheet until it passes through, and then sawn through along the marking line. For each edge, the saw is driven into the sheet again, with a new direction of the blade.

A reciprocating saw will do an excellent job of cutting drywall already on the wall, if you have one.

Such holes are cut out with a grinder if they fall on a metal profile. Each cut is longer than the edge of the hole. It's not scary - the extra gaps will be hidden with putty.

Method number 3 - round holes

A circle of small diameter is usually cut out after installing drywall on a wall or ceiling.

The fastest way to make the cut is with a drill or screwdriver. Depending on the diameter of the hole, use a feather drill, crown or ballerina. In this case, you will not need to mark the entire circle: just a point in the center is enough for the pilot drill.

The hole will turn out to be perfectly flat and with neat edges - the main thing is to hold the tool firmly during work and not press too hard on it

You can also get by with a hand hacksaw if its blade is narrow enough to turn. The markup is applied using a compass, or a box is drawn around with a pencil, socket boxfor which the cutout is intended.

Then a hole is drilled under the blade of a hacksaw and carefully sawn through the drywall according to the markings. If the saw deviates significantly from the mark, start the cut away from the starting hole.

A hacksaw for metal or a fox saw for drywall is suitable for holes of medium and large diameter, at least 5 cm

This method most often gives holes of non-ideal geometry. They can be easily finished with sandpaper or a file, cutting the cardboard with a knife.

Method number 4 - cutting without tools

When you need to make a cut, and there is no special hacksaw or other tool, you can get by with a knife and a hammer. The scheme is simple: you need to cut through the cardboard and the top layer of gypsum on one side of the sheet, tap with a hammer along the edge of the figure, squeezing it out. Then cut the cardboard from the back along the contour of the bulge, finally squeeze out the figure, freeing the hole.

With this treatment, the gypsum layer crumbles along the contour of the cutout, so the edge turns out to be sloppy, soft. It is easy to fix it with putty.

Method number 5 - curly cutting

From drywall, you can create shapes of any intricate shape.

Bends of a large radius are cut with a jigsaw or a hand hacksaw. To do this, the sheet must be conveniently placed on a hill: 2 chairs, stacks of other sheets, or something similar. Make sure that the support area is sufficient and the sheet does not break under its own weight.

Large curved lines - for example, for wall cladding with an arch - are best cut before mounting the sheet on the wall or ceiling

Mark up the sheet, for example, by tying a pencil to a thread, fix the other end of the thread in the center and draw a circle. Complex shapes are drawn by hand or from a template.

Move the jigsaw or hacksaw along the markings slowly and with minimal pressure to avoid breaking the sheet. At first, go around sharp corners smoothly: finish them already on the finished figure with a hacksaw, file or knife.

Some figures, especially angular ones, are more convenient to cut with a knife according to a pattern. Procedure:

- make a mold - a model of the figure that needs to be cut. Better to use wooden planks;

- measure the location and circle the pattern with a pencil on one side of the drywall;

- drill a through hole in several corners of the figure;

- focusing on the holes, attach and draw a pencil around the figure on the other side of the sheet. For asymmetrical shapes, do not forget to flip the workpiece, mirroring the image;

- check if the drawings on both sides of the sheet match;

- again attach the template and cut the sheet with a knife exactly along the contour as deep as possible;

- repeat on the other side of the sheet;

- gently squeeze out or knock out the cut out shape with a hammer;

- modify the cut lines, corners with a knife or file.

Sometimes it makes sense to cut a complex shape after the sheet is fixed. The ideal tool for this job is a reciprocating saw.

You can use a fox or an ordinary hacksaw to create complex shapes, having previously drilled holes along the width of the canvas in the corners of the pattern

The location of the cut should be foreseen before attaching the drywall to the wall or ceiling, so that later the canvas does not fall on the metal profile.

How to remove gypsum dust?

When cutting drywall, very fine dust is formed, which is then difficult to remove. On smooth surfaces, it leaves white stains even after you wash the floor for the 3rd time, and clogs very tightly and reliably on porous or corrugated surfaces.

The easiest way is to prevent contamination. Use a jigsaw or other power tool to connect vacuum cleaner. As a rule, there is a special round connector on the back of the case.

Cover the floor with newspaper or oilcloth. Moistening them will help the dust settle and hold on better, but if moisture gets on the drywall, it can ruin it.

Give preference to cutting with a clerical knife or circular cutters: practically no dust is formed when the gypsum layer is broken

Vacuum up the bulk of the plaster before cleaning the floor.

To clean a porous or matte finish - porcelain stoneware, textured linoleum - prepare a mixture of vegetable oil and water. The ratio is 1: 100, that is, 100 ml of oil per 10-liter bucket. Having washed the floor with such a solution, you will draw in the floor particles from the pores and recesses: they will all collect in an oil film on the surface. You can finally clean the floor with a vinegar solution.

A glossy floor, for example a tiled floor, will relieve a warm light pink solution of potassium permanganate from white stains.

Conclusions and useful video on the topic

This video presents a tool for fast cutting of strips, based on a magnetic disc cutter:

Here is a multifunctional construction knife - a cutter with a built-in tape measure:

The main ways to make a hole in drywall are shown in detail in this video:

Cutting drywall, even without experience and a special tool, is quite a feasible task for a home craftsman. However, using some tricks and tools, you can make this work easier and faster, as well as cut out the most intricate shapes.

Have you already faced the need to cut drywall? What tool did you use, were you satisfied with the result? Join the discussion of the article in the comments.