Any repair usually begins with the preparation of the premises, namely: dismantling of old finishes, as well as unreliable structures. One of the preparatory stages is the dismantling of the screed, which has lost its operational properties.

Despite the complexity of the process, you can perform this operation yourself using special tools. Agree, this will allow you to save a lot of money that you can spend on the purchase of quality materials for repairs.

Further in the article, a step-by-step process of dismantling the old cement-sand screed will be presented, including the features of the preparatory work. Based on the information below, you can quickly disassemble the screed, without the help of professionals.

The content of the article:

- What is a screed?

- Repair or dismantling?

- Tools and protective equipment

-

Dismantling the screed with your own hands

- Method number 1 - the use of impact devices

- Method number 2 - cutting concrete with a special circle

- Method number 3 - dismantling the screed with a diamond drill

- Conclusions and useful video on the topic

What is a screed?

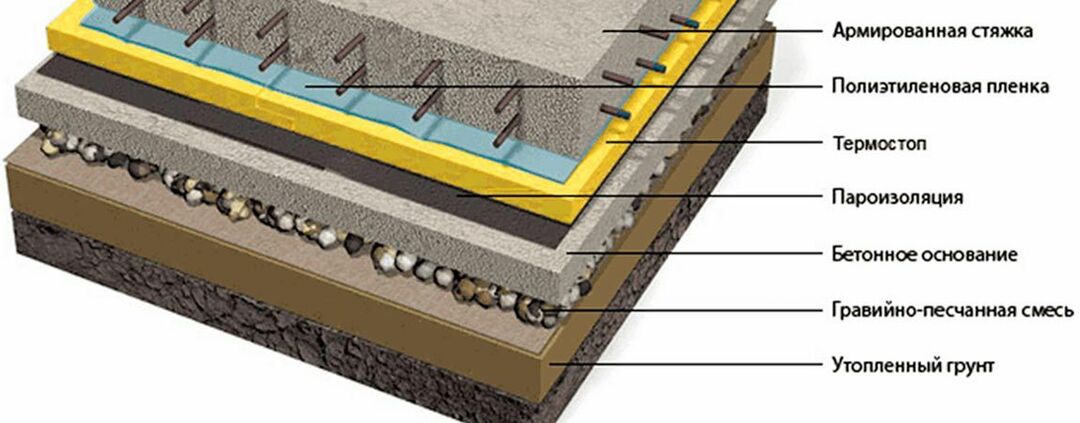

Floor screed - an intermediate layer with a thickness of no more than 4-5 cm, connecting the reinforced concrete base and the finishing floor covering. The structure can be monolithic (cement-sand mixture) or composite (several layers of gypsum cement).

A well-implemented screed performs several important functions:

- levels the base and creates the necessary slopes;

- takes the load of load-bearing structures;

- protects floors from external influences;

- allows you to raise the floor level to the required height.

In order to obtain maximum strength, the cement-sand structure is reinforced with a metal mesh, since it is subject to shrinkage.

Functionality floor screed, its strength, thermal insulation depends on the quality of its composition.

Cement-sand screed distributes the loads over the underlying layers, depending on the further placement of furniture and equipment in the room

Unlike the composite structure, the monolithic screed is not very durable, so it is not so difficult to remove it. In this case, it is important not to overdo it, so as not to damage the load-bearing walls, and not to punch a hole in them.

Repair or dismantling?

Over time, the flooring loses its performance characteristics: the cement composition begins to crumble, peel and crack. At this stage, it is important to decide whether it is worth restoring the screed or it is better to disassemble it.

Often, homeowners prefer the second option, since dismantling is much cheaper than rebuilding.

There are several nuances that will help you decide to dismantle the screed:

- It is necessary to lower the floor level.

- Too flimsy floors of the lower rooms.

- Repair of communications and pipes under the screed is required.

- The installed screed was made of poor quality cement.

The restoration of the screed only makes sense if it was installed relatively recently, but for some reason it began to crack.

It is pointless to repair the "starting" coating of the 50s, since the degree of its damage is too great. It will be cheaper to dismantle the coating yourself.

To install the screed after dismantling the old coating, it is better to use lightweight materials, since the ceiling may not withstand the load of the concrete mixture

The procedure for disassembling a concrete screed can be complete or partial, depending on the purpose of dismantling the coating and the degree of its damage.

Most often, disassembly is carried out by diamond cutting, for which you will have to prepare special electrical appliances.

Tools and protective equipment

It is quite easy to dismantle the screed in the apartment with your own hands if you have the necessary equipment with you. But first of all, you should stock up on bags made of durable material for garbage disposal.

So, prepare the following tools in advance:

- devices for diamond cutting and drilling;

- perforator, jackhammer, circular saw;

- seam cutters with diamond discs;

- crowbar, sledgehammer, chisel and hammer.

Electrical appliances allow you to remove the main part of the screed in the shortest possible time. As for the tools for manual dismantling of the coating, they are used only in places without electricity or with a small amount of work.

Of course, the process is rather slow and noisy, but it can still be used as an auxiliary one.

When working with electrical appliances, it is extremely important to control the depth of destruction of the cement-sand layer so as not to accidentally damage the floor slabs

Since the dismantling of the screed is not only a laborious process, but also “dusty”, the performer must provide himself with proper protection before starting the disassembly.

Protective equipment should be purchased in advance: respirators, goggles, earmuffs, gloves, overalls and helmets. So, in the process of work, you do not have to worry about your safety.

Dismantling the screed with your own hands

The procedure for disassembling the rough floor covering is carried out in several stages. To begin with, it is necessary to make a special hole in the screed, from which dismantling will take place. This can be done using any of the tools listed above.

Then the screed is divided into separate fragments by the impact method. The final stage - the largest parts are torn off the base and taken out of the room.

The most effective ways to dismantle a floor screed are works using:

- perforator and jackhammer;

- diamond blade for cutting the concrete layer;

- special drill for screed drilling.

If the subfloor is laid on a layer of rubble, then it is better to remove the covering with it. Since the crushed concrete is collected with a shovel, it will be much easier to slide it on a flat surface than on a rough layer of rubble.

You can find out the composition of the screed using a grinder, carefully cutting out a fragment of the rough coating, which will also allow you to determine its height

The correct choice of the power of the jackhammer depends on the thickness of the floor screed to be destroyed. By the way, do not forget about protecting the enclosing structures (walls, windows, doors) from damage by concrete fragments.

Disable beforehand electricity on the dashboard, and also shut off the water supply in all pipelines.

Method number 1 - the use of impact devices

You can start disassembling the screed from any corner by punching a hole to the very base. It should be carefully chipped off a few centimeters so that the hole gradually widens. Once you have finished crushing the intended fragment, remove the debris and keep working.

In this case, the best tool is a jackhammer. If such a tool is not available, you can use a hammer drill with a special chisel. Before starting dismantling, do not forget to turn on the percussion function.

For fast and high-quality work, the power of a conventional rotary hammer will be enough. By the way, manufacturers of such equipment recommend working no more than 20 minutes, after which the device should be allowed to rest for about the same time.

When working with a jackhammer, each section should have an area of no more than 3-5 square meters, while they can be uneven

Do not forget that working with percussion equipment is “noisy,” to put it mildly, so in the case of an apartment building, it is important to warn neighbors in advance about the upcoming repairs. If you agree on the time of repair, then there should be no problems in the future.

Method number 2 - cutting concrete with a special circle

Dismantling the concrete pavement using a conventional metal wheel is not possible. You will need to purchase a diamond wheel made specifically for concrete. Unlike a hammer drill, diamond cutting has a moderate noise level, which means it will not disturb the residents of the house.

Before starting work on the floor surface, outline the cutting lines. It is best to cut the concrete into squares of about 0.5 square meters so that you can gently lift them one by one. Do not forget to wear safety glasses and a respirator, because when working with a grinder there will be a lot of small fragments and dust.

Also open all windows in the room to create a strong draft. This will help get rid of the dust faster without waiting for it to settle.

When working with a circular saw, it is necessary to determine the level of the base - usually it is about 10 cm, on the first floors the thickness of the screed can reach 25 cm

If the procedure is carried out dry, then it must be stopped periodically. This is to ensure that the tool does not overheat.

The best option is to cut concrete with the saw blade cooled. To do this, it is enough to spray water on the furrow and disc using a conventional spray gun, provided there is no power source nearby.

Method number 3 - dismantling the screed with a diamond drill

A standard hammer drill cannot always cope with such a volume of work, so it is better to find an alternative - a diamond drill. Use it to make a lot of indentations in the concrete, then beat off the areas with the largest number of holes along the edges with a lance.

Like any other tool, the hammer drill can overheat, which can significantly slow down dismantling. To prevent this from happening, you can purchase or rent another hammer drill to alternate them in the process.

Since this procedure still does not differ in high speed, like the technology of cutting with a diamond wheel, in this case it is better to enlist the help of a friend who will clean the area behind you.

Experienced craftsmen recommend maintaining a right angle when drilling, because the slightest deviation to the side can cost you a drill.

Regardless of the power tool chosen, this method of dismantling will still be more efficient and faster than breaking the cement pavement with a crowbar and hammer.

If you have a perforator or a jackhammer in your arsenal of tools, then dismantling the cement-sand screed will cost you almost free.

Conclusions and useful video on the topic

You can find out how to dismantle the old layer of cement-concrete screed with your own hands from the following video:

This video shows the process of removing the concrete coating on the loggia using a jackhammer:

Guided by the instructions presented in this article, you can remove the cement-sand screed yourself. There are several options for dismantling the subfloor, which differ only in the type of tool used in the disassembly process. By choosing any of the presented methods, you can quickly dismantle the concrete screed without hiring workers.

If you have experience in dismantling a cement-sand screed, you can share your impressions with our readers. Tell us what difficulties you had to face in the process of dismantling the subfloor by leaving a comment under the article.