Malfunctions happen in any technique, regardless of the manufacturer. Whether it's a famous German brand or its Chinese counterpart. With the difference that the second one has them more often.

The breakdown of such an irreplaceable device as a gas water heater creates a lot of inconvenience. If the malfunction is not related to a gas leak, in most cases, the Oasis gas water heater can be repaired by yourself. We will talk in detail about what kind of breakdowns are most often diagnosed in the speakers of this popular brand among users, as well as about ways to eliminate them in this publication.

The content of the article:

- Varieties of brand geysers

- The internal structure of the "Oasis" column

-

Frequent malfunctions and their elimination

- Problem # 1 - Burner Flame Won't Ignite

- Problem # 2 - the flame ignites and goes out

- Problem # 3 - the device goes out after a few minutes

- Problem # 4 - Leaking Column

- Problem # 5 - reduced pressure and poor water heating

-

How can I extend the life of my column?

- Features of using batteries

- Column heat exchanger quality

- System water quality

- Overheating of the gas column

- Conclusions and useful video on the topic

Varieties of brand geysers

By the type of water heating, the columns are divided into two types: flowing and storage.

The former heat a continuous stream of water passing through the internal coil under the pressure of the plumbing system. The work of the second provides for the preliminary filling of the tank by analogy with electric boilers.

Heating water takes a certain amount of time, depending on the capacity of the tank. This type of water heater is extremely rare and is not in demand among the domestic buyer.

Flow-through gas columns are most widespread, primarily due to the rapid heating of water. This article will consider this particular type of column.

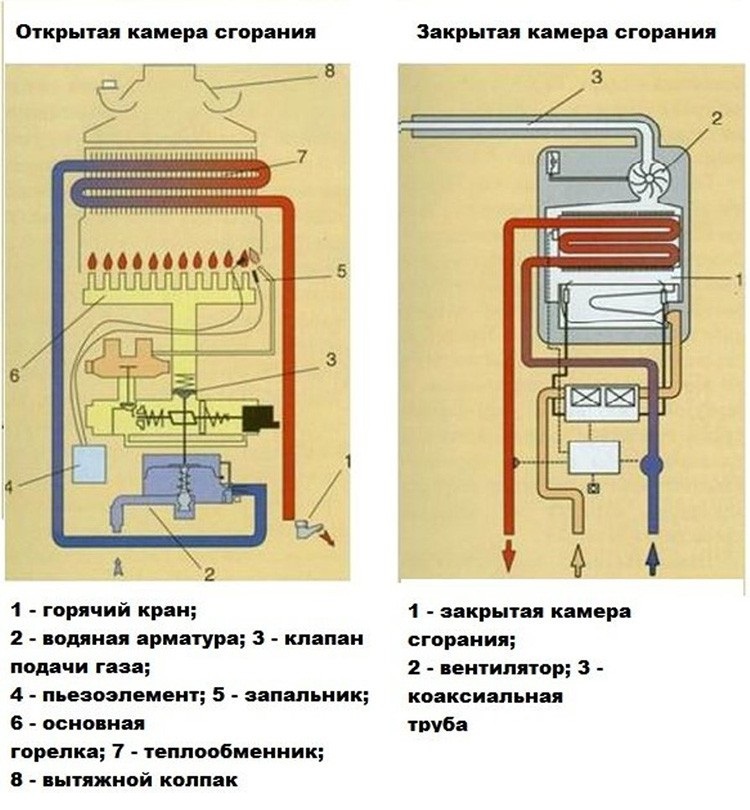

Depending on the method of removing the combustion products, Oasis gas columns are: chimney and turbocharged (smokeless).

Chimney columns have an open combustion chamber and natural exhaust through the chimney. For turbocharged engines, a closed-type chamber with forced draft

A distinctive feature of the latter is its own ventilation system, made in the form of coaxial double-circuit chimney. Consists of two pipes nested one inside the other. The combustion products are discharged through the inside, and air from the street enters the gap between the pipes.

Forced ventilation turbocharged the columns are powered by an internal fan. This requires an increased power supply compared to conventional chimney instruments. Therefore, many smokeless models are powered from the mains.

The internal structure of the "Oasis" column

Before proceeding with the search for malfunctions of the Oasis gas column and choosing a way to eliminate them, you need to clearly understand what type the device belongs to, know the device, the principle of its operation.

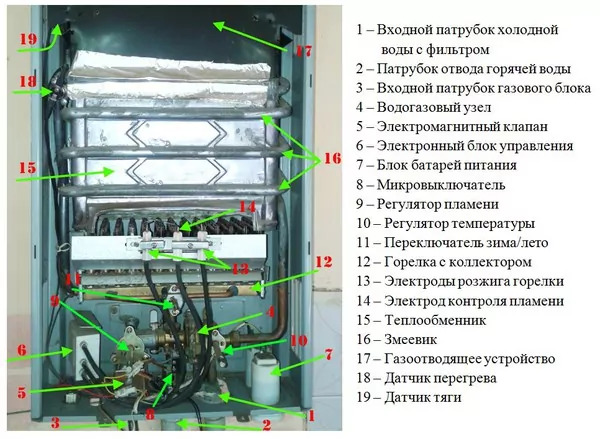

The layout of the Oasis gas column assemblies is typical for most models of Chinese-made flow columns

Above in the diagram, the device of a typical gas water heater is considered, which is also typical for Oasis columns. Let's consider further how the most common type works chimney flowing model of the brand with automatic ignition.

When the tap is opened, water is supplied through the inlet to water-gas block that includes ignition and gas supply. As soon as it ignites, a signal is sent from the flame sensor to the electronic unit to stop sparking.

Further, the water passes through a coil rigidly fixed to the heat exchanger, which is heated by the burning gas. The coil transfers heat to the outgoing running water.

When the tap closes water-gas the unit shuts off the gas supply. Burning stops and the column goes into standby mode for opening the water tap.

An important condition for the normal and safe operation of the column is the removal of combustion products through the ventilation chimney. If the hood is absent or insufficient, the draft sensor is triggered and the column turns off.

The overheating sensor is responsible for the timely shutdown of the column when the maximum temperature is reached. It is an essential element of the column to provide overheating protection.

Maintaining the required temperature regime is an equally important condition for fire safety and a long service life of the column. Overheating negatively affects the condition of all elements, especially the heat exchanger, which leads to their premature failure.

Frequent malfunctions and their elimination

Before proceeding with troubleshooting in the Oasis brand column and choosing a remedy, you must make sure that there is a normal water pressure in the system and draft in the chimney. It is better to check the draft with a candle or a match, the flame should deflect well until it goes out.

Let's consider the most frequent malfunctions that appear during the operation of Oasis dispensers, the possible causes of their occurrence, and ways of elimination.

Problem # 1 - Burner Flame Won't Ignite

If the Oasis gas column does not light up, there may be several main reasons. Let's talk about the main ones.

Insufficient power supply to the column

Insufficient or no power supply. The most probable and simple reason for this malfunction lies in discharged batteries. If a crackling discharge is heard during the opening of the tap, there is a spark, the pressure is normal, but the gas does not ignite, then the reason is most likely in the batteries.

They lose their capacity over time. Their power drops, they cannot give the required current to the load. It is only enough to start the high-voltage generator, and the power is not enough to open the solenoid valve.

Deteriorating contacts in the battery compartment due to corrosion and dirt can also cause ignition problems. Corrosion can be caused by leaking batteries or moisture entering the contacts from the outside.

Elimination: replace batteries to new ones. Alkaline cells should be installed. First you need to check the status of the contacts. If necessary, wipe them with alcohol, or clean them with emery, a knife or a file. If corrosion damage is caused by moisture ingress, identify the source and repair the leak.

For smokeless the lack of ignition may be due to a malfunction power supply unit. Only in this case there will be no spark discharge.

Weak pressure at the outlet of the water heater

Deterioration of the flow of water through the column is a common phenomenon.

If the water pressure in the system is normal, and at the outlet of the column is weak, then there may be several options:

- the filter at the inlet of the water block is clogged;

- the throughput of the heat exchanger coil is disturbed due to scale;

- clogged mesh divider (aerator) on the hot water tap;

- a piece of scale got into the flexible hose supplying hot water to the tap.

Remedy: remove, clean, rinse the mesh filters under running water. Replace flexible hose. Flush the heat exchanger.

If there is salt deposits on the filter, it is necessary to boil it in a 10% citric acid solution for 15 minutes

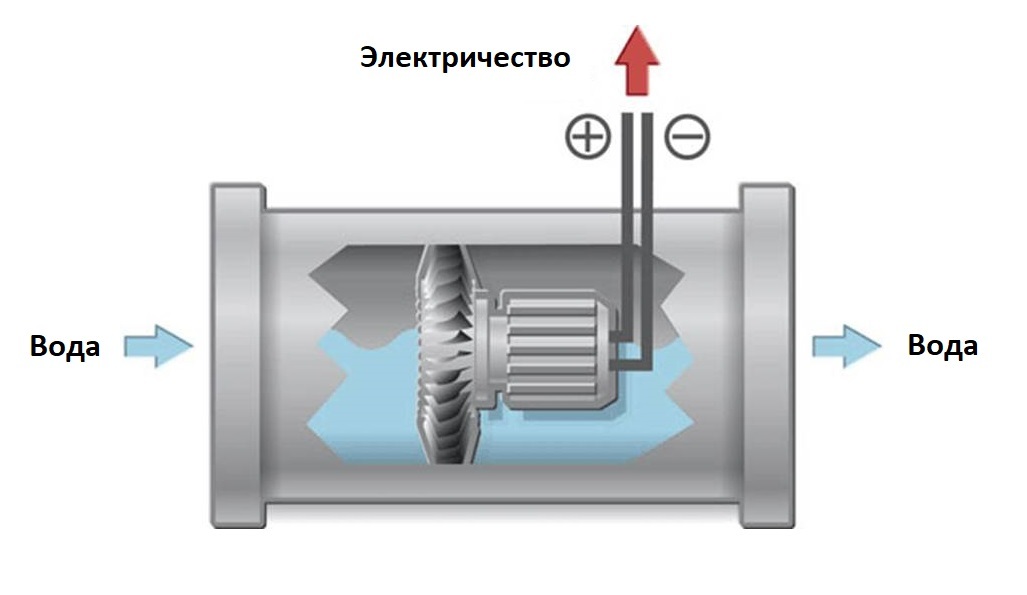

Malfunction of the water unit

Under the pressure of the incoming water flow, the diaphragm pushes the stem, which opens the mechanical gas valve and depress the button microswitchactivating ignition.

This mechanism can fail for the following reasons:

- the membrane is worn out, over time it loses its properties, elasticity, breaks;

- the stem is stuck.

Remedy: disassemble the water unit. If the threaded connections become stuck, treat them with WD-40 anti-corrosion agent or brake fluid and leave for half an hour. Then replace the membrane, lubricate the stem, spring and oil seal. It is better to install a new membrane with a silicone one, it will last longer.

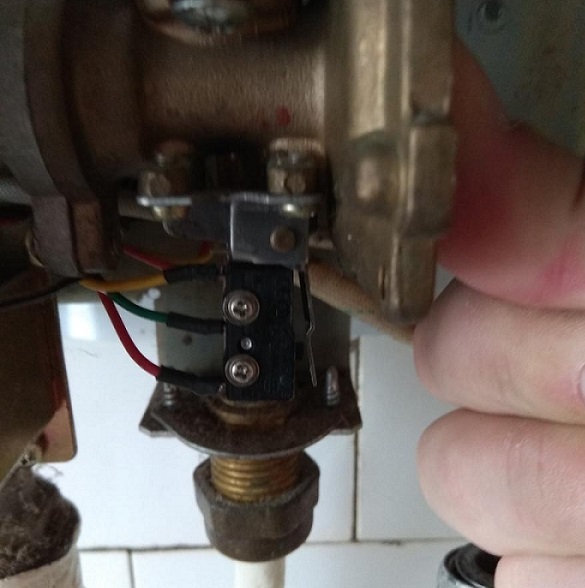

Malfunction microswitch or solenoid valve

You can check the health of the microswitch and the solenoid valve multimeter. To do this, it must be switched to the resistance measurement mode with the minimum limit. Connect the probes to the m terminalscircuit breaker and alternately press and release the button.

If the readings of the device change from one Ohm to infinity, then the switch, with a high degree of probability, is operational. If the readings do not change - microswitch defective.

To check the solenoid valve, you need to measure the resistance of the solenoid windings at the connector terminals. It should be about 400 ohms between the black and yellow wires and the yellow and red wires. Between the red and black wires - about 7 ohms. If the measurement results differ significantly, the solenoid valve is defective.

Sometimes traces of corrosion and moisture are found on the microswitch, in which case it must be replaced after the leak and its consequences have been eliminated

Remedy: these elements are not repaired and must be replaced.

Problem # 2 - the flame ignites and goes out

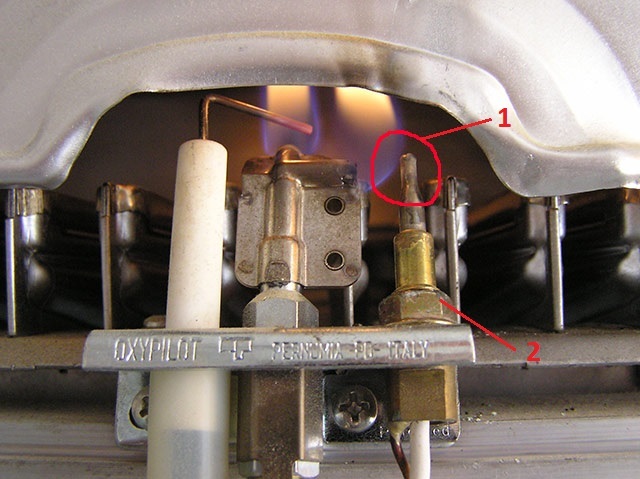

This happens when the electronic unit does not receive an ignition signal, stops the ignition and shuts off the gas. The cause may be a malfunction flame sensor or carbon build-up on the sensor.

Remedy: Lightly clean the sensor with a fine emery cloth (zero grade). In this case, one should not be too zealous so as not to damage the metal coating. If the specified procedure does not give a result, it is required flame sensor replacement.

Problem # 3 - the device goes out after a few minutes

Such a malfunction is often associated with poor traction or overheating.

Remedy: clean the chimney, reduce the water temperature by adjusting the flame and pressure, do not dilute hot water with a mixer.

Problem # 4 - Leaking Column

To determine the exact location of the leak, it is necessary to remove the front panel and carefully inspect all the components of the column. Most often, leaks occur in a water block or heat exchanger.

Leaking stem oil seal

The water-gas unit has one design feature that is not visible in its normal position. There is a hole in the back wall through which the rod controls the microswitch lever. It often leaks through it when the stuffing box is worn.

This feature of the device waterblock the gas water heater "Oasis" can be seen only from the back side when removing the unit.

To detect an oil seal leak, it is enough to inspect the attachment point microswitch. If there is moisture, and the top of the block is dry, it means that the oil seal of the water unit stem is leaking.

Remedy: take out the batteries, remove the unit for their installation. Unscrew the nuts on the water block inlet and outlet. Disconnect the water supply pipe (hose) and radiator pipe. Disassemble the water assembly, replace the oil seal or the entire stem.

Radiator leakage and its elimination

Heat exchangers made of copper and copper-bearing alloys. The reason is that manufacturers often use alloys in which the percentage of copper is less and less.

During operation, as a result of corrosion and mechanical damage, small holes begin to appear, violating the tightness of the radiator. These are the so-called "fistulas". In these places, the heat exchanger begins to pass water.

By the way, even a high-quality copper heat exchanger is not protected from rapid destruction - corrosion occurs under the influence of stray currents arising in the water supply system due to improper grounding of the column or in case of violation others operating rules gas-using equipment.

When the first signs of a leak appear, do not tighten with action. A small seepage can soon turn into a trickle and a fountain, water will get on other nodes, which can lead to their failure

Elimination: you can replace the heat exchanger with a new one, but this will cost a third of the column price. This is often not justified, it is much easier to solder it without disassembling the entire column and removing the radiator.

Before proceeding with soldering, you need to drain all the water from the radiator, otherwise it will be problematic to warm up the pipeline. To do this, it is necessary to shut off the water supply to the column, disconnect the inlet pipe from the pipe, place a container under it, open the hot water tap.

When the water drains off, a purge must be done to remove any residues. You can use a vacuum cleaner or compressor. If such devices are not at hand, you can also blow it out with your mouth. To do this, you need to select a rubber hose of a suitable diameter and put it tightly on the coil, strengthen the connection with a crimp.

Soldering can be done in two ways: with a gas torch or with a soldering iron.

Soldering with a gas torch

For soldering you will need gas canister burner, sponge, tin-copper flux paste, solder.

Start by warming up the leaked tube to evaporate any remaining water. Clean the soldered area with a sponge. Apply flux paste. Warm up again until the color of the flux changes from gray to silver.

By touching the hot tube with the solder rod, ensure that the tin spreads evenly over the surface. It is important that the solder melts not by the flame of the burner, but from the heated tube

To prevent flux residues from causing corrosion, it is necessary to remove them with a damp cloth.

We have provided a detailed instruction on soldering copper pipes with a gas burner in this material.

Soldering the column with a soldering iron

Prepare a powerful soldering iron of 100 W or more, POS-50, POS-61 or other solder with a melting point of at least 200 degrees. Flux: rosin or solder fat, aspirin tablets can also be used. The use of a building hair dryer greatly facilitates warming up.

The place of soldering must be cleaned with zero, until all traces of corrosion are removed from the metal surface. Then skimrub it with alcohol or thinner.

Heat the soldering point well with a soldering iron. Excellent results are obtained by additional heating with a construction hairdryer. Oblude soldering iron tip with a piece of solder. Apply a small amount of flux to the soldering area and immediately tin the metal surface with a soldering iron. Try to maintain the fluidity of the solder by occasionally adding flux. Bring the thickness of the solder to 1-3 mm.

With good heating, a thin layer of solder is quite enough to reliably eliminate the leak and prevent the destruction of the pipeline at the soldering point.

Problem # 5 - reduced pressure and poor water heating

Signs scale formation in the heat exchanger are a decrease in the flow of water at the outlet of the column and its weak heating. In this case, the column may not ignite well, and the radiator overheats due to poor heat exchange with water. This triggers the thermal protection sensor and turns off the column.

Clogged radiator fins also leads to overheating. When they become clogged with debris, scale, it becomes difficult for the combustion products to exit into the chimney, which can lead to burnout of the heat exchanger skirt.

Water hardness is the main reason for the deterioration of the pipeline capacity. The presence of calcium, magnesium and other impurities contributes to the formation of scale and reduces heat transfer. Heating greatly enhances this process.

Scale reduces efficiency, increases gas consumption to achieve the desired temperature. If you do not take measures to remove it, deposits will grow even faster, up to the complete blocking of the water flow.

It is impossible to use a column with heat exchanger tubes clogged with scale. This will lead to local overheating, cracks in the coil and the need to replace it.

Remedy: flush the heat exchanger with a special solution. There is a wide variety of reagents available for professional use. They do the best in descaling without damaging the piping.

Most chemicals contain solutions of various acids. Their concentration and composition are selected in such a way as to effectively dissolve salt deposits, but to act as gently as possible on the inner surface of the pipeline. The choice of a suitable reagent should be based on the material of the heat exchanger.

For example, reagents intended for copper radiators cannot be used for pipelines made of galvanized and stainless steel and vice versa.

The highest quality flushing is carried out using special equipment (boosters). The effect is achieved through repeated circulation of the reagent, its heating, reverse, and the use of special formulations. The cost of such equipment, as well as services, is quite high. Buying boosters is more justified for professional use.

Good results can be achieved in less costly ways using available tools and reagents.

The most popular and proven heat exchanger flushes are citric acid, vinegar, decalcifier and other acid cleaners. It is important to observe the dosage - exceeding the concentration of the active substance can damage the pipeline

For descaling, usually 10 - 20% solutions are used. For 1 liter of water, 100 g - 200 g are taken antiscale or citric acid or 9% vinegar. The greatest effect is achieved when the solution is heated to 80 - 100 degrees.

Flushing can be done in two ways:

- without dismantling the radiator;

- with the removal of the heat exchanger.

To flush the radiator without removing, there are a number of steps to be taken. First, turn off the water by substituting a container for draining. Disconnect the outlet pipe, open the tap. Then unscrew the nut connecting the coil to the water block. Connect the funnel from the cut plastic bottle to the coil inlet with a flexible hose.

Then fix the funnel above the heat exchanger. Pour the working solution into the funnel in small portions until foam appears at the other end of the coil. The procedure is to be carried out for 4-6 hours - until the end of the chemical reaction, focusing on the released foam, or using acidity indicators.

WITH dismantling heat exchanger flushing is performed as follows: first, disassemble the column, remove the radiator, burner. Then the plate is cleaned from soot and soot. After that, the radiator is placed in a large metal container with water, the reagent is poured into the pipeline and the container is heated. At the end, the heat exchanger must be rinsed with cold water and a 10% soda solution.

How can I extend the life of my column?

The longevity of a speaker depends on many factors. Most of them are laid down at the manufacturing plant, the rest are determined by the operating conditions.

By observing some rules and recommendations, you can significantly reduce the number of breakdowns and extend the life of the column.

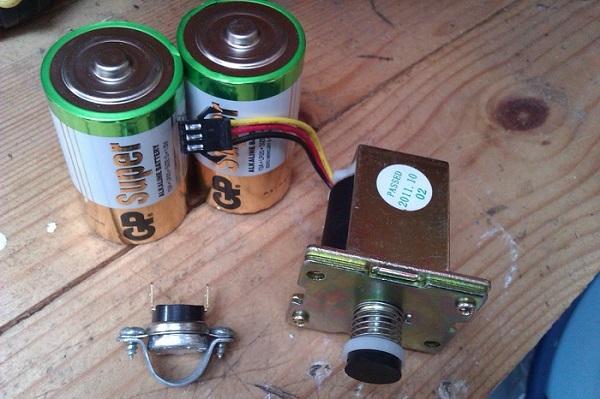

Features of using batteries

Of all the parts, batteries require the most frequent replacement. For gas water heaters, you should choose only alkaline batteries made according to the Alkalin power technology of standard size "D" and the first letter "L" in the designation - LR20. Their capacity and service life are five times longer than that of saline ones: from 1 to 1.5 years.

It is better not to buy items that are too cheap, they may turn out to be fake. It is possible to install NiMH or Li-Ion batteries, but their price with a charger is higher

Quality batteries start at $ 1.2. There is a radical way to reduce the cost of replacing batteries - converting the speaker to power from the mains.

To do this, you can buy a special 3 V power supply, or use a 5 V mobile phone charger with an additional stabilizer. The main requirement is that its power is sufficient for ignition, which occurs at a supply voltage of 3 V and a current of 350 mA.

For cases of power outages, you can always keep batteries in stock, fortunately, alkaline shelf life is 5 years and more.

Column heat exchanger quality

When choosing a column, you should pay special attention to the quality of the heat exchanger. The type of metal and its quality have a large impact on the life of the radiator. They are made of galvanized steel, stainless steel, copper.

The most durable stainless steel, but inferior in thermal conductivity to copper. Accordingly, they are less economical and have lower efficiency. Copper ones are the most efficient in terms of heat transfer, but also the most expensive.

When replacing the heat exchanger with a new one, pay attention to the thickness of the metal and the weight of the radiator. Quality shouldn't be too light

The factor of the high cost of copper leads to the fact that manufacturers save as much as possible on the thickness of the heat exchanger wall, bringing it down to 0.5 mm, which significantly reduces the service life. For the same reason, other metals are added to copper. The alloy obtained in this way can have unpredictable properties. As a result, such a heat exchanger cannot even be soldered.

System water quality

If the water in the system is subjected to frequent chlorination, this will adversely affect the condition of the copper heat exchanger. Combined with thinner pipe walls, this can quickly lead to corrosion and the appearance of holes.

Increased water hardness in combination with heating is no less problematic. Scale deposits require periodic flushing.

You can improve water quality by using aquafilters and magnetic softeners. Details and selection rules filter for water purification from the water supply is given in the following publication.

Overheating of the gas column

Overheating is the most important factor that can lead to malfunctions and shorten column life. It is important not to bring the temperature to 65 degrees and above.

To reduce the risk of overheating the water, do not use a mixer to cool it down. Change the temperature only with the dedicated flame and water flow control knobs.

Conclusions and useful video on the topic

Clearly about the repair of the gas water heater and about the fistulas in the following story:

How to clean a gas water heater with chemistry and solve the problem of low water pressure:

Compliance with these simple rules will contribute to the long-term operation of the geyser without breakdowns and repairs. It is important to remember that a gas leak or poor ventilation can lead to tragic consequences. At the first sign of a smell of gas, you need to call the emergency service "04".

Would you like to tell how you personally repaired the Oasis brand gas water heater? Share your experience with other visitors to our site, tell us about the difficulties with which you happened to collide in the process of disassembling the column, add a photo - the comment form is located below.