Along with the increase in the efficiency of modern heating equipment, the complexity of the units increases and the requirements for its maintenance increase. Agree, it is extremely unpleasant if, after a year or two after installing the device, you find condensate in the gas boiler: what to do in this case, we will tell you below.

If urgent measures are not taken, then the equipment itself and the chimney will begin to collapse. At the same time, inside the house equipped with a heating system, the walls will become damp, red smudges will form, black mold will appear, and the finish will become unusable.

A well-chosen and correctly installed chimney will solve all problems. A condensate drain will also help to cope with the situation, which will significantly extend the service life of the chimney system. From the article we have proposed, you will learn what condensate is, how to get rid of it and what the chimney should be.

The content of the article:

- What is condensation?

-

Why does moisture appear in gas boilers?

- Fighting condensate in an atmospheric boiler

- Dew prevention in a turbine boiler

- Feature of condensing boilers

- Is it allowed to drain condensate into the sewer?

- Chimney requirements for gas boilers

- Chimney installation rules

- Prevention of condensation

- Determination of the likelihood of condensation

- Conclusions and useful video on the topic

What is condensation?

Condensate is a liquid that settles on the walls of the chimney as a result of temperature differences. In modern gas equipment, the exhaust gases are at a low temperature.

Reasons for the appearance of condensation:

- improperly insulated chimney;

- sharp temperature drop;

- cold pipes;

- clogging of the smoke channel;

- low temperature of exhaust gases (ideally, the temperature should be at least 100 ° C);

- a very long chimney pipe, resulting in excessive cooling of the smoke;

- rough chimney walls (collect more water than smooth ones);

- structural irregularities;

- traction problems.

During the operation of a gas boiler, in addition to water, carbon dioxide and other chemical compounds (oxides) are also emitted.

Since modern boilers are periodically turned off, the chimney walls are cooled from top to bottom. Condensation forms when the gas temperature drops to 40-60 ° C

Under the influence of high temperatures, oxides react with water and form corrosive acids (nitric, hydrochloric, sulfuric, etc.). They are deposited on the surface of the equipment together with condensable vapors. Aggressive acidic environment leads to rapid destruction of the chimney.

What is the danger of the resulting moisture:

- if condensate freezes in the deflector or at the mouth of the pipe, the chimney section is blocked, as a result of the draft decreases, which can lead to the formation of backdraft and combustion products enter the house, causing poisoning its inhabitants;

- large amounts of water can extinguish flames, causing carbon monoxide to enter the room.

In addition, if moisture gets into the boiler furnace, its walls will collapse. As a result of destruction, toxic combustion products will partially enter the house.

Condensation will destroy the chimney. If the problem is not corrected, a complete restoration of the pipe will be required in the future.

Waste gases contain water in the form of steam. When the temperature of the gases decreases, the vapor becomes supersaturated and droplets form. In the case when the gases are incandescent, the formation of condensation occurs at the colder walls of the chimney, where liquid droplets settle.

Why does moisture appear in gas boilers?

In addition to condensate in gas boiler chimney moisture can also form in water pipes. The main reason lies in the temperature difference.

Also, the appearance of "dew" on pipelines is influenced by:

- improper ventilation (insufficiently powerful hood);

- high level of humidity in the room;

- incorrect operation of heating equipment.

The device of a gas boiler does not allow you to completely get rid of condensate. However, it is in your power to reduce the rate of moisture formation and its amount.

Fighting condensate in an atmospheric boiler

If the house has an atmospheric wall or floor standing gas boiler, then the combustion products are heated to 170-200 ° C. The gases formed during combustion also contain water. However, it does not condense, but turns into steam and is discharged through the flue duct along with other smoke and volatile soot particles.

When starting floor gas equipment after a long idle period, a small amount of condensation is allowed, which will evaporate after the boiler warms up. In the cold season, the boiler works non-stop, so the appearance of liquid is unlikely

If condensation forms in the chimney, then the problem is in the poor-quality thermal insulation of the chimney. Moreover, the formation of condensate drops on the smoke channel can occur both due to insufficient insulation, and from excessive insulation.

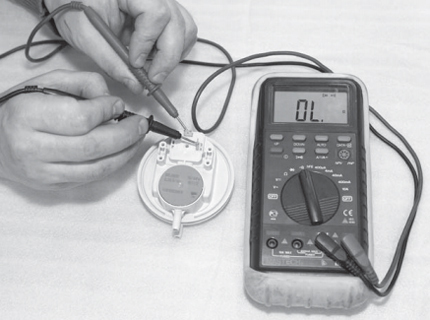

In pipes made of stainless steel, the problem of condensation can be solved by installing condensate neutralizer and additional equipment with a drainage element for the pipe settling on the surface condensation moisture.

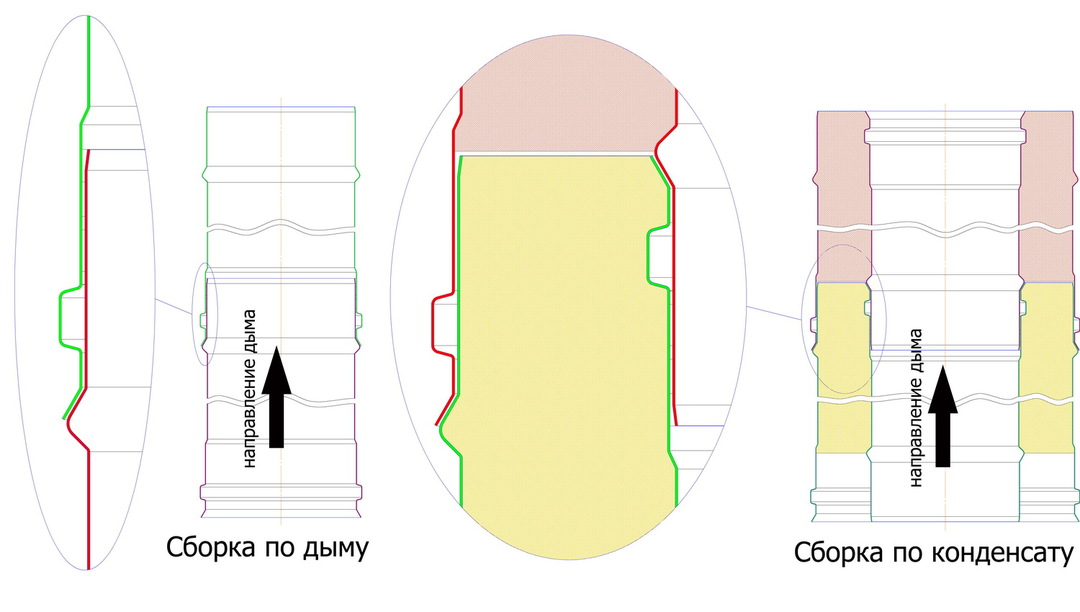

When assembling ordinary metal chimneys and sandwich chimneys, be sure to follow the order assembly and connection of elements, which provides for the spontaneous drainage of condensate outside the smoke channel.

Dew prevention in a turbine boiler

Closed burner models are equipped with coaxial chimney. It has a slope of 3 ° towards the outside, i.e. from the boiler, it provides spontaneous drainage of condensate to the street.

The internal channel of the coaxial system is constantly cooled by the air flow from the outside, so that the temperature difference during normal operation is minimal.

The standard length of the coaxial smoke exhaust system is 1.2 meters. If extension is required, (always indoors) the distance should not exceed 6 meters. There must be at least 0.6 m between the outlet of the outer part of the coaxial chimney and the nearest obstacle (wall, large tree, etc.).

If the boiler is equipped with a coaxial chimney, problems with the formation of condensation occur during frosty periods. They are solved by insulating the part of the smoke channel located outside the house, strengthening ventilation or starting the boiler at full capacity.

When using a boiler with a coaxial chimney in northern regions, it is advisable to insulate the outer part of the exhaust pipe. Condensation can be prevented in this way. gas boiler chimney. After all, the difference between the temperatures of the incoming air stream and the outgoing flue gases will be reduced.

It is possible to temporarily supply the boiler with an air supply from the room. Most turbocharged models of floor-standing and wall mounted gas boilers designed for the possibility of arranging separate supply and exhaust systems. You just need to find the plug of the hole to which the exhaust pipe should be connected, and slightly open it.

With a slightly opened cover for the exhaust duct, you can wait out the frost. Then it must be covered tightly. Even in these cases, increasing the boiler power during the frost period helps. In automated systems, a temporary reduction in the interval between the temperatures of activation and shutdown of the boiler set by the owners works well.

Feature of condensing boilers

The ideal solution would be a condensing boiler that is correctly balanced with the heating system, correctly configured and operates in the appropriate mode. In this case, the appearance of condensation is absolutely not harmful, because its energy is rationally used by the system itself.

The amount of gas saved directly depends on the amount of condensate formed. The condensation heat generated during the operation of the equipment is collected and redirected to the heating circuit. The efficiency of such a boiler is 98%.

Is it allowed to drain condensate into the sewer?

During the operation of a gas boiler, oxides are formed, which react with water vapor. As a result, carbonic and sulfuric acids are formed, the average pH of which is 4. For comparison, the pH of beer is 4.5.

The acidic solution is so weak that there are no restrictions on discharge into the public sewer. This rule applies if the formation of condensate has occurred on the pipe of a gas boiler operating in an apartment.

The only condition is that the condensate must be diluted with waste water 1 to 25. If the boiler capacity is more than 200 kW, it is necessary to install a condensate neutralizer. This requirement is indicated by the manufacturer in the equipment passport.

It is not possible to collect condensate into an autonomous sewage system that diverts wastewater to a septic tank with anaerobic bacteria or to a deep cleaning station using anaerobes and aerobes. It will destroy the biological environment involved in the cleaning process.

Chimney requirements for gas boilers

Today, in the construction of chimneys for gas boilers, various materials are used, most of which are impractical. The workmanship also leaves a lot to be desired.

Chimney made of asbestos cement. In the past, there was no alternative to such chimneys. Their main advantage is their low cost.

Disadvantages:

- installation is carried out exclusively on vertical pipe sections;

- large weight and length, which complicates installation;

- the joints are not tight;

- the resulting moisture is absorbed into the walls;

- exhaust gas temperature not higher than 300 ºС.

It is important to correctly connect the boiler to the chimney. A tee is used for this purpose.

If a tee is used in the chimney, the installation is carried out "through the smoke". In its absence "by condensation"

A condensate drain and a cleaning hatch are required.

Brick chimneys. This material is not recommended for the arrangement of systems with gas boilers. According to the requirements specified in the collection SNiP 41-01-2003, the flue ducts for gas processing equipment must be smooth and gas-tight to class P.

If, according to the characteristics of gas tightness, a brick smoke channel is quite suitable, then there can be no talk at all about the smoothness of the walls inside the pipe. Even if the seams of a brick pipe are perfectly grinded with mortar flush with the brickwork, during operation the relief will still appear due to the difference in the density of the material and the binder.

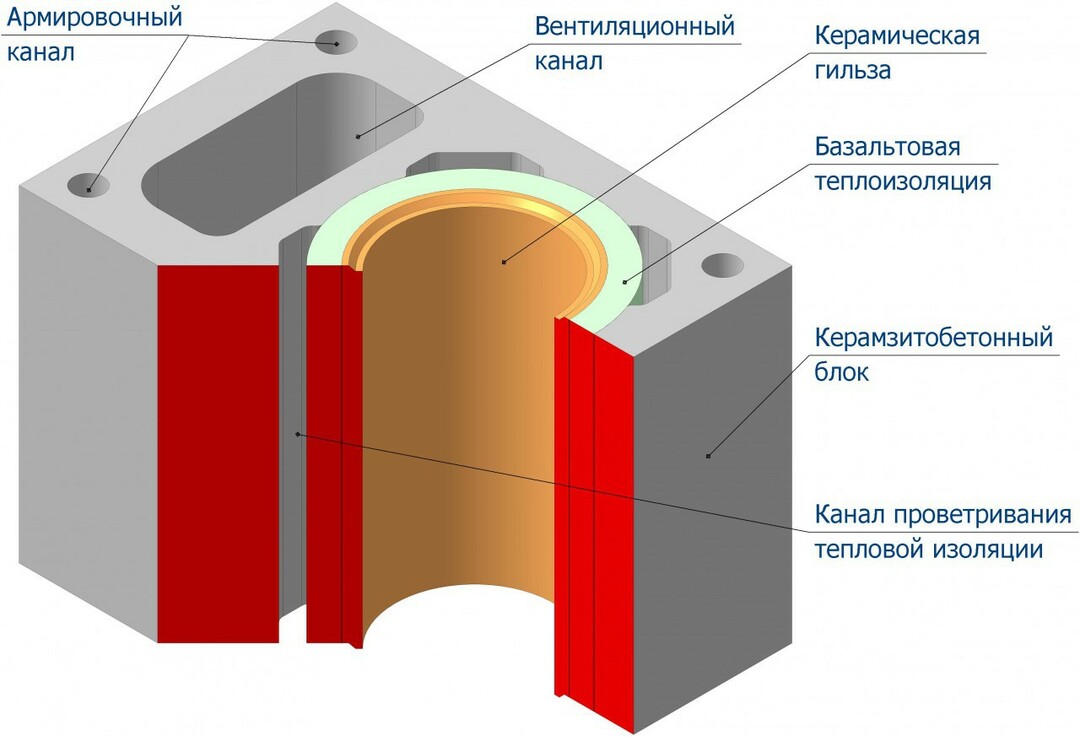

The ideal solution would be to install a metal sleeve inside a brick channel or assemble it from ceramic modules. A brick pipe with a metal or ceramic insert inside can serve without problems for more than 30 years.

For the same purpose, a furanflex lining is suitable. This polymer sleeve is made of a composite (plastic reinforced with high strength fibers). It is resistant to acid condensation and has low thermal conductivity. The permissible temperature of use is up to 200 ºС.

Ceramic smoke ducts. This material is strong and durable. Ceramic chimney resistant to aggressive acids, easy to maintain and fireproof.

Ceramics can quickly heat up and take a long time to cool down. The installation of such a chimney requires the participation of specialists. The downside is the high cost.

Galvanized and steel. When exposed to moisture, steel rusts. The maximum shelf life of such pipes is up to three years. Galvanized chimneys, protected by a zinc layer from rusting, serve for five or more years.

If moisture does not penetrate into the boiler, it accumulates in the lower part of the chimney (in the house), this leads to the appearance of an unpleasant odor. At the same time, it is a vulnerable place where acid collects, which over time "eats" this area.

Stainless steel pipes. An impeccable choice for arranging the flue gas channel of a gas boiler. Its installation will cost several tens of times less than the construction of a brick chimney. The walls are smooth, soot and tar will not settle on them, the gas density is quite high.

To assemble the chimney, you can purchase a set of single-layer modules or buy elements of a sandwich system. You can assemble such a structure without much effort with your own hands. The main thing is to observe the direction when forming the connecting nodes.

Insulation as well as chimney finishes improve the aesthetics of the building, which gives the home a more well-maintained appearance.

Advantages of stainless steel chimneys:

- due to the round section and smooth surface provide good traction;

- are sealed;

- they quickly overcome the condensation threshold;

- easy to maintain;

- fireproof;

- durable.

The quality of steel, welding seam, joints between elements is also important.

When sealing seams, you need to pay great attention to the sealant. Some brands "turn to stone" and crack during operation

The fact that chimney repair is much more expensive than competent installation at the stage of installing gas equipment is often not taken into account.

Chimney installation rules

The entire system must be insulated, waterproof and protected from aggressive materials.

Basic principles applied during installation:

- the chimney should be collected by the "condensate";

- each joint is treated with a sealing compound;

- it is better to retreat from the vertical by a maximum of 30%;

- the length of inclined sections, built at an angle of no more than 30º to the horizon - up to one meter;

- components of the same section are used along the entire length of the channel.

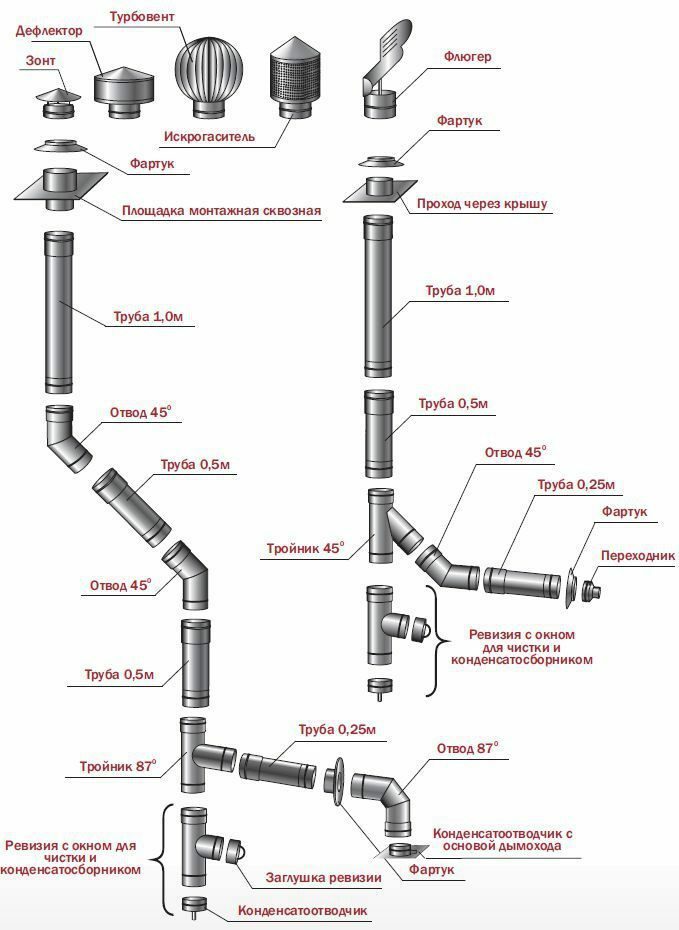

It is recommended to install ready-made chimney kits, which are available in specialized stores.

Placing an acid-resistant sleeve and a condensate collector makes it possible to postpone the dismantling of the old chimney and saves a significant amount. However, be prepared for less cravings.

Recommended parameters of the flue system for gas boilers:

- for the manufacture of the chimney, it is necessary to use corrosion-resistant steel of the AISI 321 type;

- minimum thermal insulation - 50 mm;

- the system must include: a tee with a condensate trap, as well as a protective cone over the upper section of the chimney.

When choosing a chimney, you should pay attention to these characteristics.

Prevention of condensation

Forgetting about the moisture in the chimney will never work. The formation of condensate is inevitable, although with constant operation of the gas equipment, the “drops” that have settled at startup will evaporate on their own and will no longer fall out while the unit is operating at full capacity.

To reduce the amount of moisture generated, when starting up the boiler, reduce the circulation in the system. Let the boiler heat the coolant in the heat exchanger to at least 600WITH. Then you can increase the speed of the pump. Do not let the temperature drop below 300WITH

How to reduce the amount of condensation:

- insulate the chimney channel;

- clean the system in a timely manner;

- use a steam trap.

If condensate accumulates in a gas heating boiler, then a container should be installed to collect excess liquid. The condensate drain is a stainless steel container in which the resulting moisture is collected.

It is also recommended to modernize old chimneys by installing a condensate drain tank in the lower part.

A device is mounted under the outlet channel or branch pipe of the gas equipment. Also, a permanent drainage system is installed into the sewer.

It is better to prevent the problem with the formation of moisture in the chimney than to spend time and money on solving it.

The optimal solution for eliminating condensation will be to equip the pipe with an acid-resistant stainless steel channel, a drain and an additional collector.

Moisture prevention measures:

- adhere to all norms during the construction phase of the building;

- when installing the chimney, strictly follow the project;

- regularly maintain the smoke channel using specialized chimney cleaners;

- modernization of existing pipes (insulation, insertion of stainless steel liners);

- monitor the draft power and clean the chimney in time.

The chimney is insulated with mineral wool or fiber insulation. To insulate a brick chimney, plaster is used, which is laid in seven layers.

Determination of the likelihood of condensation

Calculations can be carried out if condensate is formed as a result of a large release of steam and overheating of the walls of the chimney, and the power of the operating equipment is known. The average rate of heat release is 1 kW per 10 sq. m.

The formula is relevant for rooms with ceilings below 3 m:

MK = S * UMK / 10

MK - boiler power (kW);

S is the area of the building where the equipment is installed;

UMK is an indicator that depends on the climatic zone.

Indicator for different climatic zones:

- south - 0.9;

- north - 2;

- middle latitudes - 1.2.

When operating a double-circuit boiler, the resulting MK indicator should be multiplied by an additional factor (0.25).

Conclusions and useful video on the topic

The following video will acquaint you with information on how to protect the boiler from condensation:

Features of work and advantages of installing a steam trap are presented in the video:

Condensation in the chimney is inevitable. Since this cannot be avoided, we have shown you how to reduce moisture quality and protect equipment from corrosive liquids.

It is recommended to reinforce the chimney with stainless steel plates, install a condensate trap and monitor the presence of draft. Do not forget about cleaning the chimney, as well as preventing the condition of its walls.

If you have a successful experience of "fighting" condensation, share your secrets in the comments. Readers who have any questions can ask the specialists online.