During repairs in the kitchen, it is almost always necessary to replace or rearrange the gas stove, and therefore to reconnect it. It is advisable to entrust the work to a qualified, certified gasman, but you still have to choose and buy the equipment yourself.

In this article, we will look at gas hoses for gas stoves, which is better, how to choose and connect equipment, and also talk about what flaws are found in gas hoses, and why they are dangerous.

The content of the article:

- Ways to connect gas stoves

-

Varieties of modern gas hoses

- Rubber reinforced hoses

- Reinforced PVC sleeve

- Bellows hoses for plates

- How to choose the best option?

- Differences between a gas hose and a water hose

- Features of connecting a gas stove

- Compliance with security measures when connecting

- Conclusions and useful video on the topic

Ways to connect gas stoves

More recently, about 30 years ago, gas hoses were not common and stoves were connected steel pipe. Such a connection is very reliable and durable, because the pipe will not leak, withstand high temperatures and is resistant to oil. However, it is not possible to move the stove connected in this way, even by a centimeter. That is why, and also because of the complexity of installation, now such a connection is not practiced.

The first to replace the rigid connection were the so-called oxygen hoses, made on the same principle as car tires. The warp is woven from super-strong cord threads, and they are already filled with rubber on both sides. Such hoses withstand enormous pressure - up to 20 atmospheres, they are available in a wide range of diameters (from 16 mm) and lengths, are easy to install and are quite cheap.

Rubber is susceptible to aging and cracking, especially under the influence of oil, and the use of gas hoses with a service life of less than 10 years is prohibited in an apartment. This is why oxygen gas hoses are a thing of the past.

Rubber-fabric hoses - the closest heir to oxygen, differ only in the use of a special textile thread instead of cord. They are produced and sold today and are inexpensive. However, due to the fragility of rubber, they also cannot be used in apartments, but for connecting the stove to a gas cylinder in the country, this is perhaps the most convenient option.

Varieties of modern gas hoses

Rubber hoses today are more of a rarity than an everyday product. They are too short-lived, and black rubber looks unaesthetic, and you can't paint it.

Therefore, when you have to choose which hose to buy to connect a gas stove in an apartment, it is better to focus on one of the 3 main options: bellows, rubber reinforced and PVC hose. Let's consider each of them in more detail.

Rubber reinforced hoses

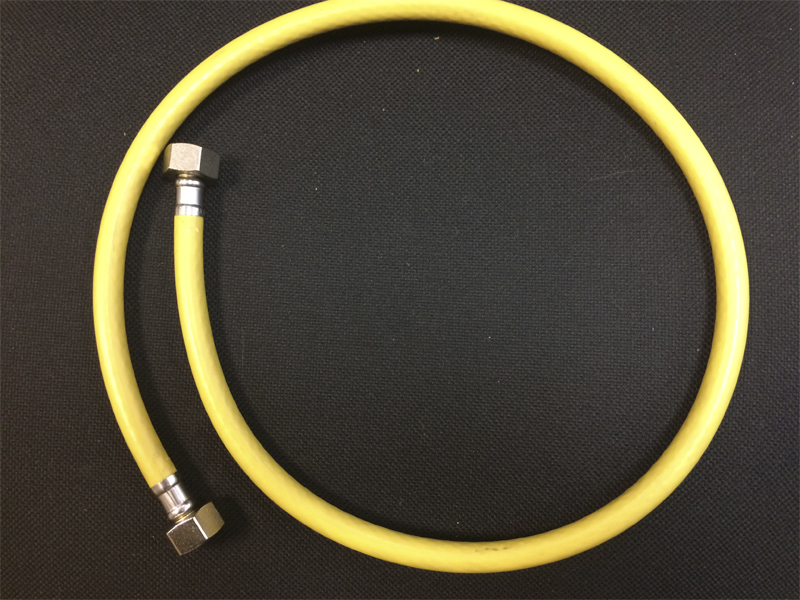

Perhaps these are the most common, inexpensive and reliable gas hoses. Outwardly, this eyeliner is absolutely the same as a tap, only in a braid instead of blue or red, yellow threads are woven.

These hoses are three-layer. Inner - polymer layer to prevent cracking and leakage. Medium - vulcanized rubber - the basis of the hose, its stiffness and density. Outer lash made of steel threads - for protection from external damage and additional rigidity.

Reinforced gas hoses are an exact replica of their plumbing counterparts. Their distinctive feature is the weaving of yellow threads into the braid of the product.

The advantages of these hoses are low price and wide assortment, ease of installation and durability. Disadvantages - relatively short service life (about 10 years), high electrical conductivity (inserts - dielectrics are required).

Reinforced PVC sleeve

They are also three-layer: a reinforcing mesh is poured between two layers of polyvinyl chloride. In this case, the inner layer is usually black, and the outer one is either completely yellow or with a yellow stripe.

It is by their color that they can be most quickly distinguished from water hoses - but not the most reliable, the marking is worth rechecking.

PVC gas hoses are very similar in appearance to garden hoses for water, but differ from their counterparts in composition

These gas hoses have several advantages:

- do not conduct electricity - this is the only modern option, the use of which without a dielectric is absolutely safe;

- suitable for various combustible mixtures - both in the city gas pipeline and for mixtures from a cylinder;

- withstand pressure up to 0.63 MPa, which is 20 times more than the maximum working pressure in the network;

- available in different lengths - from 40 cm to 5 m;

- the cost is several times lower than for bellows analogues;

- polyvinyl chloride is much stronger and more durable than rubber, much less susceptible to cracking;

- shelf life 12 - 20 years. Considering that the service life of a gas stove usually also does not exceed 20 years, this is quite enough.

Among the disadvantages, only a relatively small rigidity can be noted.

Bellows hoses for stoves

A bellows is a corrugated pipe made of rings or spirals, resembling a sewer corrugation or a hose from a shower mixer. Bellows hoses are of 4 types: ordinary corrugated, solid metal-plastic, metallic look, with stainless steel corrugation; with polymer spraying on top of stainless steel - to protect against electricity; with thermal protective valves that automatically shut off the gas supply in case of overheating.

Gas hoses of this design have a number of advantages: they are safe, the likelihood of leakage is minimal; withstand pressure up to 6 atmospheres, which is 200 times higher than the maximum operating pressure in the gas supply network; look aesthetically pleasing; durable - the manufacturer's warranty is usually at least 10 years, the service life of such a hose for a gas stove is about 30 years.

This type of sleeves is recognized by professionals as the most reliable and safe, but their cost is sometimes 5 times higher or more.

In addition, they can withstand temperatures up to 200 ° C, bend and stretch a little, are fixed in a given shape with corners - you can arrange nicely and safely, do not rust or crack, are protected from any external influences, have sufficient rigidity - not break and do not twist, easy to install. In most models, the corrugated fitting is either soldered or made in one piece - this is much more reliable than a clamp or glue.

Even with such a significant list of advantages, these hoses also have disadvantages. In addition to relatively high prices, they are dangerous by electrical conductivity (if there is no polymer spraying), and therefore can burn out from contact with household appliances or even the cable of the stove itself.

How to choose the best option?

Choosing a hose to connect the stove to the gas pipeline is not an easy and very responsible task, because you risk the safety of your home and life, as well.

In order to choose the appropriate option from all the variety described above, you need to decide on several parameters:

- Hose length. When connected, it should sag a little - just enough so that the stove can be moved aside for cleaning or if something falls over it. Installing the hose under tension is not permissible - it is dangerous. The most popular sizes are from 1 to 2 m, but there are products from 40 cm, and the maximum length of domestic hoses reaches 4.5 and even 7 meters.

- Connection type. At one end of the hose, which is screwed to the plate, there will always be a nut with an internal thread - "mother", but at the other end, from the side of the gas valve, there can be either the same nut or a union with an external thread - "dad". Pay attention to which connector your gas tap has.

- Connection diameter. Half-inch nuts are most commonly used, but there are ¾-inch nuts and more exotic options. Measure the threads on your equipment.

- Metal compound. Avoid contact of white metal (steel) with yellow (brass) - it is unsafe.

- The cross-sectional diameter of the hose for the full operation of all burners must be at least 1 cm.

- See which outlet is on your stove. If it is angled - great, but if it is directed into the wall - it can be dangerous. A hose wound directly onto such an outlet may break up, when the stove is pushed against the wall, and this is fraught not only with a weak gas pressure, but also with a leak. To avoid such a situation, purchase an additional metal fitting-angle. If there are 2 outputs on the stove, you will also need a plug.

- Assess your financial capabilities. Remember that expensive hoses will not only be safer and more beautiful, but will also last many times longer.

- If the hose can touch a microwave oven, dishwasher or other electrical equipment, insulation is required. Choose PVC sleeve or bellows polymer sprayed hose.

Having decided on all of the above questions, you can reduce the number of hoses to choose from to 2 - 4 pieces, and only choose from them in terms of price and appearance. Also, to buy a quality gas hose, please pay attention to some details.

For use in the country, with a gas cylinder, you can also purchase an inexpensive rubber-fabric hose - it will be more convenient and more likely to be found with the required diameter

Contact only specialized stores and demand quality certificates for the goods - this is your right and a guarantee of safety.

Don't be fooled by offers to buy the branded sleeve at half price - most likely it's a low-quality Chinese knock-off. But do not refuse to buy just because it is made in China - many brands transfer their production of certified goods to this country, without lowering control and standards quality.

See how the braided spigot is connected. Soldering or solid cast the product is excellent, the glue is bad.

Check the warranty period and service life in the product passport, compare them with the type of hose and the price.

In addition, buying an expensive branded bellows gas hose, beware of counterfeiting. Examine the product carefully - it should be neat, with inconspicuous seams, without flaws, even small ones.

There must be a yellow marking. Even on rubber hoses, a yellow tag is glued in a conspicuous place, on others it can be present in the braid, coloring of the top layer, on the packaging. Without such marking, it is easy to confuse hoses for gas and water, and the latter will begin to "poison" the gas, if not immediately, then in a month

Look in the technical data sheet and check the correspondence of the description to reality. Ask for a quality certificate or at least a copy of it. Too low a price should be alarming, but a normal market price is not a guarantee of quality.

Differences between a gas hose and a water hose

Connecting the hose for other purposes is extremely dangerous, because the water hose is not designed for contact with gas, which is why it quickly wears out and begins to poison. In addition, even gas hoses differ for different compositions and state of matter. So that the mistake in choosing a hose for supplying gas to the stove does not become fatal, take into account several factors.

First, absolutely everything gas hoses, regardless of type, are marked in yellow. It can be a braided thread, a yellow sticker tag on the hose itself, or a mark on the packaging and a plug, but something yellow must be present. There should not be blue and red interweaving - these are indicators of hot and cold water supply.

Secondly, the purpose of the hose must be indicated in the product passport and quality certificate. Gas hoses differ in rubber or polymer composition, manufacturing methods and performance characteristics - they cannot be interchangeable, no matter how similar they look.

The gas hose must be supplied with a special paronite gasket that seals the flange connection. A paronite gasket is placed at the exit of the slab. Only rubber seals go to plumbing - they are enough for water

Thus, it is necessary to distinguish the purpose of the hose, and if you do not fully trust the competence of the seller, be sure to ask for documents for the goods, where the manufacturer indicates that this hose is intended for gas.

Features of connecting a gas stove

The first thing you should remember if you decide connect the stove yourself - now you yourself are responsible for your life, and for the safety of the kitchen, and the stove itself. The manufacturer's warranty does not apply if the work was performed by an unqualified gas master.

If the risks do not bother you, here is a short instruction for action.

- evaluate all the initial data and, if necessary, buy the missing one;

- if the thread diameter on the hose and on the stove or faucet does not match, stock up on a suitable adapter-footwear;

- check availability paronite gaskets included with the hose. If it is not there, buy the one with the mesh;

- if the stove has 2 outputs, buy a plug and screw it tightly into the outlet farthest from the gas pipe;

- when connecting a hose with an open metal sheath, it is better not to skimp on a dielectric - a special insert with a plastic core that does not conduct current;

- install all necessary adapters, but try to minimize their number. The dielectric is screwed into the gas valve, and the hose is already screwed onto it;

- screw one end of the hose to the gas cock or dielectric, or to futorke if available;

- tighten with an open-end wrench tightly, but do not be too zealous so as not to break the thread;

- arrange paronite gasket at the outlet of the plate;

- screw the other end of the hose to the plate. The nut rotates freely on the hose so that it must not be twisted or break up;

- dissolve solid soap or mix liquid soap with water. Apply the resulting solution to all connections, including factory ones on the hose;

- open the gas tap, but do not turn on the burners of the stove, but watch carefully. If soap bubbles have not appeared at any of the joints, the stove can be used.

When connecting the gas stove yourself, remember that the hose should not come into contact with electrical appliances and wires, and also hide behind furniture - this is unsafe.

If you still have an old petal gas valve installed, it is better to replace it with a ball valve, and this can only be done by an employee of the housing office, blocking the entire riser

Compliance with security measures when connecting

Every year, explosions and fires in household gas occur in different parts of our country, causing fires and large-scale destruction, injuries and deaths. To prevent such a disaster from happening to you, do not neglect any of the safety rules outlined below, because such a risk and savings can be very expensive later on.

The hose should be one, one-piece, without extensions and unnecessary connections. Each connection is a potential leak point, and composite hoses are prohibited by GOST.

The gas hose cannot be hidden behind furniture or painted - buy one that suits you externally. It is forbidden not only for the opportunity to inspect the hose at any time, but also in order to instantly notice the malfunction and replace gas hose. The paint dries up and promotes cracking of the rubber.

The connected gas hose should be slightly slack - not taut, but also not rubbing against the floor. Otherwise, it threatens to damage the hose and gas leak.

From gas tap there should be one connection, without squeeze and branching. If necessary, call a gasman, who will bring out another tap using a pipe.

It is not recommended to use gas hoses for connecting gas stoves, the dimensions of which exceed 2 m.If necessary, it is better to lengthen or move the gas pipe - a metal gas pipeline is more reliable, safer and much more durable.

Avoid kinking or kinking the hose - this will negatively affect not only the gas pressure, but also safety. In the place of the bend, and when twisting - at the fastening of the fitting, very quickly the hose will leak and begin to poison.

Change the hose regularly, following the manufacturer's expiration date. Do not use a hose in an apartment that has a service life of less than 10 years, such as a rubber hose. After 2 - 3 years of constant use, it may become unsafe.

Do not carry out welding or soldering near the hose, avoid the accumulation of condensation. If possible, invite a specialist to any work on the gas pipeline - your own safety is always more expensive than their services.

Check regularly for leaks with a soapy solution, as the slightest leak can cause gas to build up and explode

Do not neglect electrical insulation metal hose and do not allow it to come into contact with household appliances and wires. Even if the wiring in your kitchen is in perfect order, for example, lightning striking the gas pipeline can act as a catalyst for a discharge, hose burnout and ignition.

Conclusions and useful video on the topic

The following video will discuss how to choose the right gas hose for connecting the stove:

Considering all of the above, the choice of a hose for connecting a gas stove is a very important task, in which savings should not be put above safety. Having carefully studied all aspects, you can choose and buy the best gas hose for your stove, without overpaying, but also without putting yourself, your family and neighbors at risk.

And on which gas hose for connecting the stove did you choose and why? Please tell other visitors of our site about this. Write your comments, ask questions, share your experience - the communication block is located below.