However, small volumes of gas in cylinders force the user to often buy new ones or think about self-filling. We will tell you how to refuel gas cartridges for burners with your own hands. This simple procedure will help you save your money.

In our proposed article, we consider all the refueling options available for self-realization. Provides detailed guidelines and recommendations for performing the work. Taking into account our advice, you can easily cope with filling a mini-container with liquefied gas.

The content of the article:

- Types of cartridges for tourist burners

- Filling Threaded Cartridges

- Refilling cartridges with collet connection

- Refueling of Valve Threaded Cartridges

- Transferring gas from one cartridge to another

- Conclusions and useful video on the topic

Types of cartridges for tourist burners

Hikers and hikers on hikes need a fire source for cooking. In such cases, gas burners are a convenient tool. They are also actively used in construction and in households.

Users who decide, in order to save money, to fill the gas cans on their own, need to follow the safety rules, take into account the nuances and follow the replacement technology. Then this procedure will go smoothly and without undesirable consequences.

If the collet (left) or threaded (right) gas cartridge is not completely emptied during operation, it is not necessary to discard it. It is possible to fill them from each other or from a large gas cylinder

First, you need to determine the type of connection of the cylinder to the burner.

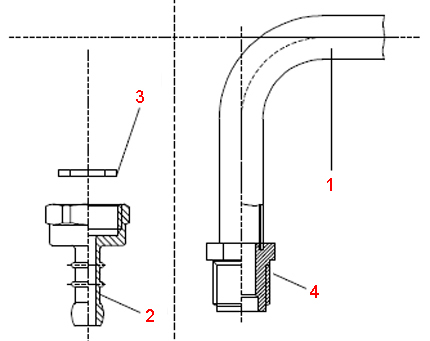

There are four types of accession:

- Threaded EU - designed for fixing the burner by screwing it onto the cylinder, complies with European standards;

- Threaded US - similar to the first type of connection with a small difference, complies with American standards;

- Collet - the burner is pushed on and scrolls a little until it locks in, there is a safety valve, it is possible to purchase an adapter, with prolonged use the mount looses and gas leakage is possible;

- Valve - fixed with a special lock, such cylinders are attached only to the burner models intended for them, the valve prevents gas leakage, in practice it has the longest service life;

- Pierced - the disposable cylinder is fastened with a slight pressure and cannot be removed until the gas is completely consumed, and cannot be refilled.

The most common replacement cartridge option for work gas burner equipped with thread. It is simpler and more convenient for regular replacement.

The most common cartridge options are designed for connection with a thread and a valve. This fastening provides a tight fit, and the safety valve prevents gas leakage

You can detach the threaded cartridge at any time, but this will not work with the pierced type. We'll have to wait for it to empty.

Regardless of the type and size of the "donor", the essence of the process is to create a sealed connection for pumping liquefied gas from one reservoir to another

Filling Threaded Cartridges

The first step before starting refueling is to find the source of the gas. The source is large gas cylinders various volumes from five to three hundred liters. Make sure your can is free of gas residues and empty it completely.

Next, you need to find an adapter suitable for the attachment of the cylinder - the gas source and the attachment of the empty cartridge. The adapter is bought or assembled by hand.

It is important that it does not allow gas to escape during transfusion. You also need to find an accurate scale that will allow you to weigh an empty can before refueling and after, in order to find out the weight of the filled gas.

Now we will describe how to fill up a gas cartridge from a large cylinder in stages without buying a new one:

- We weigh an empty can, determine its exact weight;

- Place the large balloon horizontally and fix it in any suitable way. It is worth putting something under the bottom of the cylinder so that it is higher than the top. This trick will make it easier to transfer gas;

- Using a previously prepared adapter, we connect the empty canister to the gas source;

- We close the valve of the adapter on the can, and unscrew the valve of the large bottle;

- Slowly unscrew cylinder valve and start refueling;

- While the movement of gas through the hose is heard, refueling occurs, if the sound disappears, you can shake the can. This will allow you to add some more gas;

- After the sound of the overflow has completely disappeared, close both valves, unscrew the can, shake it. If you hear sound floundering filled with liquefied fuel, the refueling was successful;

- You should also check the tightness of the can with a soapy solution;

- Then we weigh the filled canister and determine the weight of the gas inside it. If there is more gas than necessary, then you need to bleed off the excess.

Usually, 10 minutes is enough to fill the mini-bottle. This period of time allows you to fill in about 150 - 180 g of liquefied blue fuel.

Since it is necessary to pour liquid gas from a large cylinder, you should turn it upside down or put it on its side. If this is not possible, then it is worth at least tilting, taking into account the specifics of filling the tank.

Refilling cartridges with collet connection

To refuel cans with a collet connection, it is worth purchasing an adapter or adapter designed for this purpose. Its cost in online stores usually does not exceed ten dollars.

The design of this device is as follows: a tube made of polymer or metal alloy is equipped with a union nut on one side. It provides a sealed attachment to a large gas cylinder, and on the other side has a collet clamp with a handle that opens or closes the flow of gas into the cartridge.

So, to refuel small gas cylinders with a collet mount from a large one, a series of actions should be carried out sequentially:

- We weigh an empty can;

- We close the valve in the collet clamp on the adapter;

- We fasten the union nut to the gas source (it can be a cylinder of any volume);

- We check the tightness of the adapter connection with soapy water;

- We turn the large cylinder with the valve downward, since we are interested in liquid gas;

- We attach the collet clamp to an empty tourist cartridge;

- With the help of the handle, we start up the gas, which will fill the container for some time;

- We close the valve, unscrew the can, check its tightness and weigh. It indicates how much a full can should weigh, this is a rough guideline.

Remember that when storing the Touring Spray mini burners in hot rooms at high temperatures, the gas inside it expands. If you do not leave the gas cap, a kind of reserve volume in the can, then its inflation is possible. That is, you need to fill the can so that you can hear flop liquid gas inside.

Weighing the cartridge after refueling and comparing the indicators with the factory data on the instructions is a reliable way to make sure that the cartridge is completely refilled.

During pouring, the filling system cools down and even becomes covered with frost. Don't be afraid, just wait until everything thaws and keep working.

It is recommended to work exclusively with gloves. Always screw in the adapter carefully, as it is very easy to damage the threads, which will make further refueling of the touring gas cylinder at home impossible.

There should be no sources of fire in the room where the gas is transfused. pipe brazing burners or a hotplate that is on. Some cans cannot be refilled. For safety reasons, it is recommended to refill one cartridge no more than four times, and then buy a new one.

Many manufacturers point out the inadmissibility of refueling their products. Cylinders from well-known manufacturers tend to last longer. If dents appear on the body and other signs of deformation, you should not risk it, but it is better to throw out such a can and buy a new one.

Weighing the cartridge after refueling and comparing the indicators with the factory data on the instructions is a reliable way to make sure that the cartridge is completely refilled.

Refueling of Valve Threaded Cartridges

Refueling threaded valve cartridges requires the following pre-assembled equipment:

- Two fittings: one, with a union nut, is connected to a household gas cylinder, and the second, threaded, is connected to a gas cartridge;

- Transparent hose with which it will be possible to trace the process of gas overflow. Also serves as an adapter and connects to two fittings;

- Valves that allow you to turn on and off the gas supply from the cylinder directly at the valve;

- A filter built into the valve that prevents debris from entering and clogging the can;

- An additional valve that allows you to bleed gas without removing the adapter.

A good adapter model wins in comparison with a cheap one due to a number of advantages:

- The valve of the adapter ensures the safety of the valve of the household cylinder, which deteriorates due to loosening and tightening regularly and due to rust or other metal particles entering on the thread;

- Due to the fact that the valve is in the closest position to the valve of the cartridge, during the next cycle gas station, there is practically no leakage of excess gas, pouring it onto your hands and spraying into the surrounding Wednesday;

- The ball valve design allows you to quickly cut off the gas supply and avoid unwanted overflow and forced venting of excess gas;

- Thanks to the advantages described above, the refueling process is noticeably easier, safer and more economical.

An adapter is screwed onto the valve of a large household gas cylinder instead of a reducer. Refueling is best done in the company with an assistant and in the open air away from crowded places. Since there will be a strong smell of gas, people passing by may become anxious and call the gas service.

The refueling process for threaded valve cartridges consists of the following steps:

Step 1. First of all, you should drain the remaining condensate, bleed off the residual pressure in all cans that you plan to fill before the adapter is connected to a large bottle. This will make the refueling process a little faster.

The adapter is screwed onto the cartridge, which is turned upside down, the cartridge is slightly heated with warm hands, which increases the volume of gas and speeds up the bleeding process. Preferably drain the condensate into a plastic bottle. It smells rather unpleasant and impregnates the surrounding objects with a smell.

Step 2. The preparation of the system consists in placing the gas cylinder in a stable position with the valve directed downward and opening free access to it. Under no circumstances should the cylinder be resting on the valve. The ideal option is to hang the balloon upside down. Next, tighten the adapter and open the valve of the large cylinder.

Step 3. The adapter is screwed tightly to the cartridge. We open the valve on the adapter and start pouring gas. The cessation of the overflow noise means the end of the priming.

Step 4. The next step is to bleed off the gas in order to cool the cartridge. The procedure is performed by opening the bleed valve on the adapter. After a few seconds, the can will become cold enough, and the pressure in it will drop to the desired level. We close the valve. If necessary, it is made refilling.

Step 5. The most important step is to create a buffer cushion in the can to prevent possible expansion and explosion. We open the bleed valve and wait for the moment when the liquid no longer pours.

Never direct the gas jet towards yourself. When shaking the can, you must definitely feel flop. Also an effective method is weighing a filled can on a scale. After passing through all the steps, it is important to check the tightness of all filled containers.

Always point the end of the hose away from you when bleeding, draining condensate residues and creating a buffer cushion.

For safety reasons, it is not recommended to store the spray cans in the sun, in damp or cold places. Cold cylinders after filling are covered with a layer of condensate. To prevent rusting processes, it is worth wiping the containers with a dry towel.

Transferring gas from one cartridge to another

After using gas burners, cartridges with gas residues often remain. They should not be thrown away, since there is a possibility of gas transfer from one cylinder to another. Collet cartridges cost about half the size of threaded cartridges, have the same volume and are more common on the market.

The burners can be designed for both collet and threaded fasteners, and some models are initially equipped with adapters. Refilling a threaded cylinder with a collet will save you a decent amount of money, and collet cartridges are easier to find.

Sometimes the adapter is not a solution to the problem, since it weighs a lot and takes up space. In such cases, it is enough to simply pour gas from one cylinder to another using a simple technology and using an adapter made with your own hands from a disposable syringe.

Stages of preparing a homemade adapter:

- Use pliers to pull the needle out of the plastic. After this procedure, a hole remains, which needs to be slightly widened using a small drill or a round awl, hot on a fire.

- Next, using a knife or a file, cut or erase the plastic ribs on the tapered part.

- The end of the product from which the needle was previously protruded is cut obliquely. This will prevent the valve from shutting off the gas supply.

- From the bottom, we cut the product with a knife by about three millimeters, thereby shortening it.

After preparing the adapter, cool the threaded cartridge, and heat the collet. Thanks to this procedure, the transfusion of gas will be greatly facilitated. You can cool it in the refrigerator or freezer, and heat it up in warm water. Never bring cylinders near fire.

In the manufacture of a homemade adapter, all actions must be performed in a specific sequence. Following the steps guarantees a successful result

Transfusion stages:

- When the cylinders cool and warm up to a sufficient level (about 10-15 minutes), we take a collet cylinder, and we put an adapter made of a needle onto it.

- Then we turn the collet cartridge upside down, and we rest the product from the needle with the tip against the hole of the threaded cartridge. After that, you should press the collet can. You will hear how the gas overflows.

- When the procedure is over, you can re-cool the threaded and warm up the collet cylinders and re-pour the gas. Repeat until the next heating and cooling does not bring results.

The transfusion process takes a rather long period of time and requires increased pressure on the collet balloon, which can bring some discomfort. To eliminate discomfort, you can use a towel folded several times.

A homemade adapter is installed on a heated can. Now you need to attach a can, cooled in the freezer to it.

If there is a financial opportunity, then you can purchase a special adapter, and not make it yourself. In such cases, the process of gas transfer will be noticeably simplified.

Conclusions and useful video on the topic

The video will clearly demonstrate the procedure for filling a canister with pouring liquefied gas from a large bottle:

Refueling tourist gas cans is a workable procedure at home. For successful gas transfusion, you need to control the implementation of each stage and follow safety rules.

After several refueling, the procedure is remembered and becomes less complicated. Remember that manufacturers do not recommend refueling and using touring burner cartridges after they run out of gas.

Would you like to share your own experience while filling a gas cartridge with liquefied gas from a large one? Do you have any useful information on the topic of the article that is worth sharing with your site visitors? Please write comments, ask questions and post photos in the block below.