Modern gas stoves satisfy the end user in almost every way. Most designs of such household appliances are invariably equipped with an automatic flame ignition system.

However, despite all the perfection of modern gas stoves, the potential owner of such equipment still has to deal with defects. In particular, over time, a defect often appears when the auto-ignition of a gas stove constantly clicks, regardless of the user's actions. Why is this happening? Consider the reasons for such a breakdown and possible repair methods on our own.

The content of the article:

- Differences in circuit solutions of the ignition system

-

Reasons for auto-ignition

- Reason # 1 - moisture inside the control button

- Reason # 2 - junction formation

- Reason # 3 - mechanical connection of the contact group

- How to check if a lighter is working?

- Conclusions and useful video on the topic

Differences in circuit solutions of the ignition system

Before trying to figure out the reason for the incomprehensible "behavior" of the home gas stove or trying to perform do-it-yourself repair, it is advisable to get acquainted in general terms with the principle of functioning of the mechanism auto ignition.

According to the available information, there are two design options for such devices:

- Electromechanical.

- Based on electronic automation.

The first option assumes a double action by the user, when it is necessary to first activate (turn) the gas supply knob, and then activate (press) the ignition button. Such schemes are somewhat simpler than fully automatic schemes, but they are inferior in ignition efficiency.

A push-button control system for automatic ignition of a gas stove is a convenient modern function that excludes the use of "old-fashioned" methods - lighting matches

The second option for igniting a gas stove is more convenient. Here, the user needs to slightly drown the gas supply handle inside the landing socket by slightly pressing it and turn it at a certain angle. The efficiency of ignition of an electromechanical circuit is inferior to a fully automatic system.

Both versions of gas stove ignition systems also differ in electrical circuitry. The first design is characterized by an electrical circuit that uses a high-voltage capacitor and a simple electrical spark gap.

Another configuration for igniting the gas stove is the so-called combined configuration, where the functions of the button and the flame level control dial are combined in a single structure.

The moment the button is activated (pressed) by the owner of the gas stove leads to the supply of voltage to capacitor, the charge of which forms a breakdown voltage for the spark gap on the secondary winding of the step-up transformer. Accordingly, a spark, conducive to gas ignition.

The fully automatic design contains a slightly different circuit, where, in addition to a high-voltage capacitor, there are electronic components such as:

- diodes;

- thyristors;

- transistors.

Such a scheme works according to a somewhat complicated version, due to which a better quality ignition spark is obtained at the output. And also there is a more convenient control for the user.

Something like this looks like a classic spark gap (candle) for gas stoves. It is thanks to this component of the gas burner structure that an electric spark is formed, which ignites the gas at the moment it is turned on by the user.

The ignition unit of a gas stove itself is, as a rule, carefully packed, and it is quite difficult to get close to the electronics. We recommend that you familiarize yourself with device and principle of operation gas stove.

However, what to do when the electric ignition of a household gas stove constantly clicks, regardless of the adjustment knob? Let's talk about this further.

Reasons for auto-ignition

As it turns out, taking into account practical experience, spontaneous clicks of a gas stove lighter in most cases have nothing to do with the electronic circuit of the ignition unit.

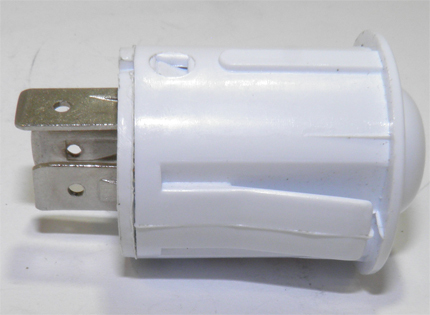

One of the many designs of button-lighters for gas stoves. Traditionally, a plastic housing and a metallized contact block are ideal conditions for the formation of oxide seals. However, there are higher quality, but expensive designs.

The reasons for the appearance of an uncontrolled spark lie elsewhere. Often the place of formation of such a defect is inner area of the button ignition control.

Reason # 1 - moisture inside the control button

Surely the owners of gas stoves had to deal with uncontrolled clicks of ignition on the gas stove after washing and cleaning household appliances.

Most likely, during the washing process, some amount of water got on the ignition control button, as a result, some of the moisture penetrated inside.

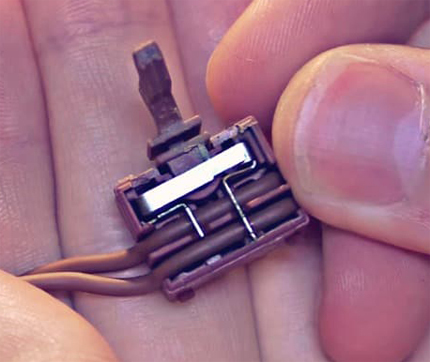

View of one of the designs of the button-lighter from the inside. With this arrangement of conductors, even a small amount of moisture, carbon deposits, soot, etc. enough to create a short circuit between the contacts

Considering that a high discharge voltage is supplied through the ignition button circuit, a small amount of moisture is enough for an uncontrolled spark to appear on the gas stove spark gap.

Usually a defect uncontrolled spark lighter in such cases, it disappears after some time. The moisture inside the button dries up, the short-circuit factor disappears, respectively, spontaneous clicks stop.

The picture shows a simple way to get rid of the defect of spontaneous sparking of the ignition system, obtained due to moisture ingress. Warming up the device for some time with all burners helps to get rid of uncontrolled clicks

Often, the correction of a short circuit defect due to "water that got after washing" is helped by lighting all the burners of the gas stove for about 15-30 minutes.

Reason # 2 - junction formation

The spas that form inside the ignition button can have different shapes. The formation of a seam can be facilitated by the same moisture that got inside the button after washing. Typically, this "water" seam is formed due to the periodic infiltration of water.

Time after time, deposits build up and eventually an oxide seam forms. In addition, grease, soot, dust can accumulate inside the button housing. All this is also precursors of short circuit between contacts.

With this development of events, you will have to disassemble the gas stove:

- remove the top panel;

- open the front subpanel;

- remove the ignition button (s).

Or, in the case of more modern designs of gas stoves, it is necessary to get to the structures disk control devices, simultaneously performing the functions of a button and a regulator of gas supply to the burners.

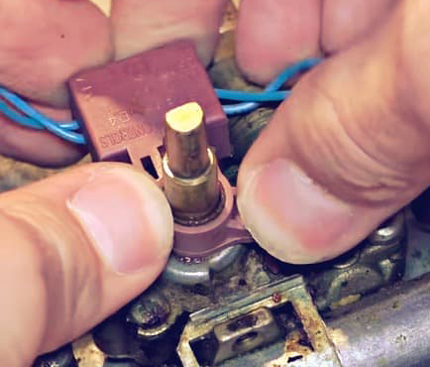

A version of the mechanism for turning on the auto-ignition and adjusting the level of the burner flame, where two functions are combined in one design. It is more difficult to remove such systems for cleaning or repair than a separate button.

After removing the part from the gas stove body, the deposits are cleaned, after which everything is assembled in the reverse order. However, this work is a prerogative gas company specialists. An inexperienced user of a gas stove in such matters is not recommended to disassemble the device on his own.

Reason # 3 - mechanical connection of the contact group

The mechanical connection of the contact group of the ignition button of the gas stove should also be attributed to the category of reasons associated with a short circuit. Such a defect, as a rule, can occur on slabs that have been in operation for a long time. True, the same malfunction is not excluded on new devices, where the quality of the components leaves much to be desired.

A mechanical connection is formed by any of the button contacts, which simply breaks off, for example, due to physical wear and tear. The broken off part is displaced from the attachment point and forms an electrical connection with another contact. In fact, the effect of the ignition button on is created - that is, the spontaneous operation of the electric ignition on the burners of the gas stove.

With such a malfunction, the only way out is a complete replacement of the component.

How to check if a lighter is working?

In order not to dismantle a potentially serviceable component in vain, it is advisable to first perform a short circuit check (short circuit).

It is easy to do this using a measuring device - a tester that supports the ability to measure resistance in the "mOhm" range.

The procedure for testing a button-lighter for the presence of a short circuit using a classic instrument for electrical measurements. Testing should be performed with the option of measuring resistances in the "mOhm" range

On almost all models of gas stoves, ignition control elements are connected with conductors through connectors. Therefore, each control can be easily disconnected from the circuit for testing. After removing the plugs with conductors from the connectors, the tester probes are connected to the free contacts of the buttons and the readings are monitored on the scale.

If a short circuit has formed inside the button body through the oxide junction, resistance measurements in the "mOhm" range will show some value in any case. When the readings of the device are equal to the absolute reference point (maximum resistance "mOhm"), there is no short-circuit defect.

We also have other articles on the website about stove breakdowns and problems with burners:

Do-it-yourself gas stove repair: common malfunctions and how to fix themWhy the gas burner makes noise: analysis of the reasons + valuable recommendations for eliminating the problemThe gas burner does not burn well: popular faults and recommendations for their eliminationConclusions and useful video on the topic

To conclude an overview of the defect of a constantly clicking gas stove, as well as the possibilities of correction, we recommend that you familiarize yourself with the thematic video below:

In some cases, the elimination of the defect is quite possible on our own. However, theoretically and in accordance with the rules, any malfunctions of gas stoves are the prerogative of special (gas) services. This approach is due, first of all, for reasons of general fire safety, and not just directly the owner of household appliances.

Have you recently eliminated the cause of the spontaneous operation of the autoignition in your stove? Share your experience with other visitors to our site, leave your comments and recommendations, add unique photos taken during the repair of the ignition button - the feedback form is located below.