Are you going to gasify your house or modernize the gas supply? The gas pipeline is one of the most valuable and dangerous communications, so its reliable protection is extremely important.

Agree, damage to the gas pipe and the leakage of this fuel can go unnoticed for a long time, and then lead to the most dire consequences. It is better to carefully study everything in advance and play it safe when arranging protection, right?

If you are interested in the insulation of steel gas pipelines, in this article you will get answers to such questions: why is it needed, what happens, in what cases and how each type of insulating material is used, how the quality check is carried out cover. We will mention all types of gas pipelines: from mains to low pressure pipes, from aboveground to underwater, we will answer all your questions.

The content of the article:

- Gas pipeline insulation functions

- Normative documents and their requirements

-

Types of insulation materials

- Polymer protective coatings

- Insulation based on bituminous mastics

- Insulation materials for small elements

-

How is insulation applied?

- On the pipes of the aboveground gas pipeline

- Insulation of underground gas pipelines

- Field Insulation

- Insulation of pipes under water

-

Insulation quality check

- In the factory

- On-site installation or repair

- Conclusions and useful video on the topic

Gas pipeline insulation functions

Today, almost every building in every settlement is connected to the gas pipeline; it is difficult to imagine the life of a modern person without blue fuel. Just imagine how many pipes are needed to implement such a supply chain!

They stretch over our heads, under our feet, deep in the earth, and even along the seabed. Every centimeter of this gas web must be reliably protected and absolutely safe, because a leak can lead to a large-scale accident, with destruction, and sometimes even casualties.

Modern underground gas pipelines are laid mainly in polymer pipes - they are not afraid of corrosion or the effects of stray currents, and they keep the temperature better

Polyethylene gas pipelines do not need additional protection, but they cannot be used everywhere, and replacement is expensive, so most gas pipes are steel.

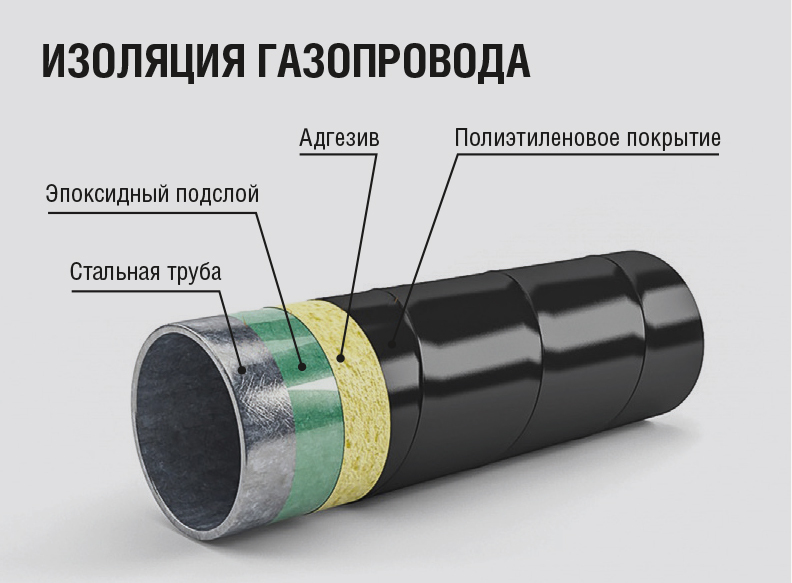

To prevent steel from rusting and collapsing, it is treated with special compounds and materials that isolate its surface from the environment. The main functions of such coatings are protection against moisture, chemical influences, mechanical influences, as well as dielectric protection.

Active electrochemical protection forms a cathodic charge on the pipe surface, ensuring its electrical stability and preventing the influence of external currents

In addition to coating, for reliable protection against stray and constant currents, underground gas pipelines are organized electrochemical cathodic protection, which ensures the removal of these charges through a special conductor to the drain substation.

For an aboveground pipeline, the protection is less solid, because it is easier to renew, and the pipes are exposed only to atmospheric moisture, regularly drying out. For offshore gas pipelines, on the contrary, in addition to reliable protection against an aggressive environment, an additional layer of weighting is required so that the pipe lies motionless on the bottom, under the waves.

Normative documents and their requirements

There are 3 main documents regulating the organization of protection of gas pipelines. RD 153-39.4-091-01 "Instructions for the protection of urban underground pipelines from corrosion." As the name implies, it does not apply to the insulation of gas pipes with a diameter of more than 83 cm - intercity and international, as well as to pipes laid above the ground or under water.

GOST 9.602-89 - a related document, which contains all the norms and calculations for the protection of underground gas pipelines. If the instruction explains how and from what to equip insulation, then GOST indicates how much of what is required - from meters of material and tools to equipment and working hours of workers.

GOST R 51164-98 Steel main pipelines. General requirements for corrosion protection. This standard fills a gap in the Trunk Piping Instructions. Their protection should be especially reliable and has its own specifics, therefore the norms of its organization are taken out in a separate document.

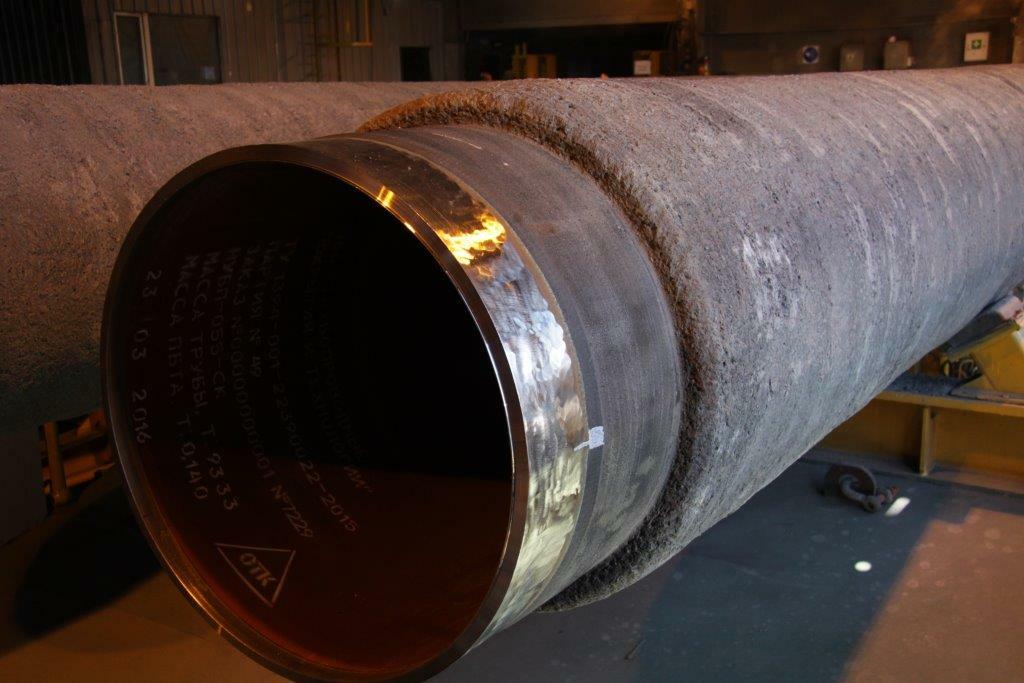

As a rule, gas pipelines of national and international importance have a diameter of more than 830 mm, their installation and maintenance is laborious and expensive.

These documents govern the following issues:

- what types of materials are allowed to be used on this type of gas pipeline in these conditions;

- how much reinforced insulation is needed, whether electrochemical protection is needed;

- who and when is obliged to provide the gas pipeline with the necessary protection;

- technology for applying insulation at the factory and in the field, as well as for repairing damage;

- consumption rates of materials and costs of other resources for work;

- the procedure for checking the quality of the coating and standards for quality indicators in all parameters for each type of insulation.

Thus, in these documents, the entire process of pipe insulation is described step by step, from release at the factory to verification after installation and during operation. There is no space left for creativity, because these are security issues.

In the event of damage or poor-quality application of an insulating coating, steel in the soil rusts rather quickly, and this threatens with gas leakage and fire

There are also separate lists that list all recommended materials and manufacturers of insulation for gas pipelines.

Given the complexity of the work and the considerable number of norms that must be observed, do not even count cope with the insulation of the gas pipeline independently, and the gas service will not accept work performed by third parties master.

Types of insulation materials

Based on the operating conditions and ease of use, there are many types of coatings for insulating gas pipes. It is sufficient to protect overground gas pipelines with 2 coats of primer and 2 coats of paint or enamel.

Pipes that will serve on the seabed are covered with a layer of concrete over the main insulation for weighting and additional protection.

Next, we will talk about the means of protecting steel pipes underground.

Polymer protective coatings

Extruded polyethylene - the most advanced and versatile protection. It is used on pipes with a diameter of 57 - 2020 mm, adheres tightly, forms a perfectly uniform continuous layer, protects against temperature and mechanical influences, and is also easy to use.

In such a coating, the steel pipe is practically not inferior in terms of protection characteristics to polymer analogs. This protection consists of only 2 layers - a hard adhesive adhesive and, in fact, polyethylene. Despite this, such a very reinforced type of coating on pipes of large diameter can reach 3.5 mm.

Extruded polypropylene is specific for its high mechanical strength: with it you can pull pipes through wells, for closed ways of laying, and do not worry that there is insulation from friction or clinging to stones and soil will be damaged. Externally and in structure, this type of insulation does not differ from polyethylene, only 0.3 - 0.5 mm thinner.

Polymer adhesive tapes are polyethylene and polyvinyl chloride, while the former are preferable, since they are 4 times stronger adhered and better protect pipes. Most often, adhesive PET tapes are used to repair and insulate pipe joints coated with extruded polyethylene, but there are also pipes that are wrapped around their entire length at the factory.

If necessary, polymer adhesive tapes allow you to completely replace the pipe protection in the field - but this requires a special automated installation

There is also a combined PET coating, in which the primed pipe is first wrapped with an adhesive polymer tape, and on top of it is protected with a layer of extruded polyethylene. It is used on pipes with a diameter of up to 53 cm, and the total thickness does not exceed 3 mm.

Insulation based on bituminous mastics

Such insulation is fundamentally different in composition and properties, primarily in the method of application. The adhesion of bitumen both to the pipe and the layers to each other is ensured by heating and melting the material itself, and not by an adhesive primer, as is the case with PET.

Such a coating is applied to a special bituminous primer, and consists of 2-3 layers of mastic, each of which is reinforced, and an outer protective paper wrapper. As a result, a continuous coating is formed that completely repeats the shape of the pipe, where the reinforcing fiberglass or mesh is, as it were, soldered into the thickness of the protection.

Fiberglass, fiberglass mesh or non-woven polymer fabric is used as a reinforcing material. Fiberglass tapes are wound with a slight overlap to form a continuous layer

In addition to bitumen, the mastic itself contains various inclusions - polymer, mineral or rubber - that provide different properties of the material. Also, modifying additives and plasticizers are added to it, which, to natural hydrophobicity and adhesion properties add elasticity, flexibility, resistance to critical temperatures and durability.

There are also tapes that connect bitumen as an adhesive and special polymer tapes. The main 2 types of such coatings are - PALT, with heat shrinkable tape, and LITKOR, made of polymer-bitumen tape. The latter, in particular, is necessary to protect the connections between pipes with different types of insulation.

Insulation materials for small elements

Base outlets, corners, elbows, condensate traps and other fittings of gas pipelines also need protection.

It is more convenient to isolate small parts at the installation site, but a factory coating is preferable, because it is more uniform and reliable

There are special coatings for this: PAP-M105 and Polur. The first is two layers of cured polyester resin reinforced with glass fibers.

Polur consists mainly of polyurethane, supplemented with technological additives and divided into a main component and a hardener. With the help of these two compounds, shaped joints are insulated at the factory, in workshops, and directly on the track.

How is insulation applied?

The main part of the insulation is applied to gas pipes, and often on shaped parts of a gas pipeline, at the factory, even at the stage of their production. However, when installing the pipeline, it becomes necessary to isolate the joints, which is carried out in route conditions - that is, directly at the installation site.

In addition, in the field, the same materials are used to repair the protective coating if no more than 10% is damaged, and occasionally even complete re-insulation of a separate area. Also, the reservoirs are isolated manually, directly on the route.

Whenever possible, welds and fittings are insulated with the same coating as the main pipe - or as similar as possible.

Gas pipeline insulation works are possible at temperatures above -25 ° С, and for polymer adhesive tapes - above +10 ° С. If it is raining or snowing, there must be a secure canopy over the work site, which will make it impossible for precipitation to fall on the insulated surface.

On the pipes of the aboveground gas pipeline

This type of gas pipeline is located in the least aggressive environment, and therefore the risk of rust is significantly reduced. In addition, damage to it is much easier to notice and repair, so elevated gas pipelines do not require insulation as such.

To protect against precipitation and atmospheric moisture, according to the standards, a coating of 2 layers of primer and 2 layers of paint, enamel or varnish is sufficient.

As a rule, a galvanized casing is used to protect flue gas pipes that require thermal insulation. Only insulation is placed under the casing, no additional protection is required

However, in case of difficult operating conditions, thermal insulation of gas pipelines is used - consistent greases, glass enamel coatings, and aluminum or zinc casings, which should not touch itself pipes.

Insulation of underground gas pipelines

In the ground, pipes are constantly exposed to moisture, and often chemical compounds and stray currents. All this can lead to metal corrosion and gas leakage, so they try to provide insulation as reliably as possible.

Each underground steel gas pipeline is doubly protected: passively - by the insulating pipe coating, and actively - through the drainage or suppression of the current by cathodic protection.

Most of the materials that we talked about earlier can be used both for basic, factory insulation, and on the track. We will tell you about the main stages and intricacies of such work further.

Polyethylene and polypropylene insulation at the plant is implemented in several stages:

- Drying pipes.

- Shot blasting to a metallic sheen.

- Heating pipes.

- Applying an adhesive backing to a rotating pipe.

- Application by extrusion, stocking or tape winding of a polyethylene layer.

- Sealing with a special roller with a fluoroplastic sheath.

- Water cooling up to 70 - 80 ° С.

- Quality control of the resulting coating.

All processes are fully automated, because computer accuracy is a guarantee of product quality.

Often, before the adhesive is applied, the pipe is coated with a thin epoxy coat for better protection and adhesion. According to regulatory documents, this is not necessary.

In the field, all stages must be preserved, but they are implemented using portable equipment - grinders and sandblasting cleaners, gas-burners and blowtorches. In addition, there are special kits for sealing joints and repairing damage - for example, shrink PET cuff or adhesive plastic tape.

To apply bitumen insulation, the pipes are also polished, but with the help of metal brushes, leaving a clean, but not smooth surface. A primer consisting of bitumen and gasoline is poured onto the cleaned pipes and rubbed with towels, and in the conditions of the track - with rags or brushes.

The bitumen insulation primer is made from bitumen and refined gasoline in a ratio of 1: 3 by volume. It is extremely important to apply it in a thin, even layer for the adhesion of the coating to the pipe.

Not more than in a day, it is necessary to apply the main coating: 2-3 layers of mastic, separated by a reinforcing material and protected from the outside with a layer of paper.

For reinforcement, fiberglass, non-woven polymer fabric or mesh is used. They are wound spirally, evenly, with slight tension and overlap.

Field Insulation

If it is necessary to repair damage to the insulation of an underground gas pipeline, or to connect pipes with different types of insulation, it is important to choose the right materials.

PALT and LITKOR coatings are used only in route conditions. Both are applied to a bitumen primer, but for the first, it is necessary to first apply a layer of bitumen and reinforce it, and then wind the tape directly onto the hot mastic. In the second case, bitumen is the bottom layer of the tape itself, so it is wound directly onto the primer, having previously melted with a burner.

Despite the external similarity, Litcor tapes should not be confused with sticky PET tapes, because the use of an inappropriate primer will hopelessly spoil the quality of the insulation.

They repair pipes with extrusion PET coating with special heat-shrinkable patches or bitumen-polymer tapes LITKOR. When factory coated with adhesive PET tape, it is used for repairs, such as Polylene. This is possible only in the warm season, because the tape does not stick in the cold and does not tolerate melting.

To isolate the welding points of pipes coated with extruded polyethylene, special cuffs are used, which are fixed by means of heat shrinkage.

The bituminous coating is repaired with the same bituminous mastics with reinforcement, LITKOR bitumen-polymer tapes or a similar roll material Isoplast-P.

It is always possible to connect different pipes in absolutely any combinations with LITKOR tapes, and if in your own both pipes are free of bitumen, straight connections can be insulated with adhesive tapes Polylene.

Insulation of pipes under water

Gas pipelines that will serve on the seabed are insulated especially carefully, because this environment is dangerous and chemical, and mechanical damage, and interruptions in pipe operation, as a rule, indicate interruptions in international gas supplies.

The main part of the pipe protection is obtained at the factory. After cleaning and drying, they are opened with an epoxy compound, then an adhesive is applied, and a polyethylene layer over it. At this stage, the pipes are similar to similar land pipes, except for the first epoxy layer, which is duplicated on the inner surface.

However, this is not all: cathodic protection is installed on the prepared pipes at the factory, and then construct a reinforcement frame and pour the outer concrete layer, often with iron ore as filler.

Concreting over the main insulation will not only protect against any damage, but also reliably nail the pipe to the bottom

As a result of such a multi-layer finish, the weight is 1 lm. pipes can reach 2 tons. It is very problematic to transport such tubes, therefore they are not allowed to be too long, and for every kilometer the offshore gas pipeline has several dozen welds, each of which must be reliable isolated.

Connection and insulation of joints takes place on a special barge equipped with everything you need. Here the pipes are welded, the seam is carefully cleaned using a shot blasting machine. Main pipes have a huge diameter, so they are heated with induction, rather than propane burners - it turns out faster, more uniformly and safer.

Then a primer is applied and a heat-shrink sleeve is installed, secured with a locking plate. The cuff is warmed up first in the middle, along the weld, and then gradually shrinks with the help of gas burners, from the center to the edges. After quality control of this stage, a lining casing is installed for pouring PPU. After it dries, the pipe is lowered to the bottom and covered with rubble.

Insulation quality check

The protection of steel gas pipelines is a responsible event, therefore each performed operation is subject to a thorough check, with the preparation of an act of completed hidden works and their entry into the passport pipeline. No matter how high-quality and correctly selected the insulation material, it will not cope with the functions assigned to it if the work technology has been violated.

The main parameters of the finished coating to be checked are thickness, continuity and adhesion to the pipe. They are measured with special electronic devices: thickness gauges, spark flaw detectors and adhesion meters, respectively. They do not damage the coating, so they allow you to control all questionable points at no extra cost.

In the factory

At factories and production bases, the thickness of the coating is checked on 10% of the pipes of each batch, in 4 places from different sides in a circle on each pipe, as well as in questionable areas.

The insulation applied to the pipes by the manufacturer is always more uniform, of better quality and more reliable than that organized in the field, even when using similar materials

Adhesion, or the strength of adhesion to the metal and between the layers, the standards require also to be checked for 10% of the product in a batch or every 100 m.

The continuity of the coating, that is, the absence of punctures, scuffing and other through violations, is checked on all insulated products throughout the entire area.

In addition, dielectric continuity of the coating, impact strength, peel area after cathodic polarization and other tests can be checked. When insulating with bituminous coatings, a test for physical properties is taken from each batch of mastic, at least daily.

On-site installation or repair

In route conditions, the quality of insulation is also checked, for continuity - always and completely, and for thickness and adhesion - every 10th insulated weld.

In addition, the width of the overlap on the factory coating is checked, as well as the relief of the insulation - for the absence of corrugations, wrinkles, air cushions and other defects.

With poor adhesion of the insulating tape to the pipe, over time it will peel off, and the pipe will be exposed to the environment

In addition, insulation continuity is regularly checked on existing gas pipelines. To do this, they do not even need to be dug out, and in case of suspicion of damage, pipes are exposed and checked not only for thickness, continuity and adhesion, but also for dielectric properties isolation.

Conclusions and useful video on the topic

Now you know everything - or almost everything - about the purpose and materials for insulating various steel gas pipelines, and also have an idea of the features of their application and checking the quality of protection.

And for greater clarity, we suggest watching a video, which tells in detail about the insulation of welded joints with bitumen-polymer tape:

Installing a heat-shrinkable sleeve on a weld seam:

Perhaps you have already come across such works, watched their implementation or were directly involved. Please add or evaluate the information provided. We'll be glad to hear your opinion in the discussion below.