Content

- 1 Pine

- 2 Linden

- 3 Alder

- 4 Birch tree

- 5 Hornbeam

- 6 Poplar

- 7 Ash

For the manufacture of furniture, about two dozen different types of wood are used, which in the global classification are divided into soft and hard types. The former are most susceptible to wear and tear, but at the same time are easy to process, and are therefore ubiquitous in production.

Pine

Soft light wood. Used in the manufacture of cabinet furniture, sofa frames and beds. It tolerates temperature extremes, resistant to decay. But in operation, the pine is fragile and susceptible to scratches, dents and other mechanical damage, so careful handling is required.

Linden

Soft, plastic, light wood with a pinkish tinge. It gives in to coloring poorly, but it stains well. If the wood is too wet, then it loses strength, therefore, when processing the array must be dried. Affected by a wormhole from which it becomes fragile. Most often used to create individual carved elements and linings.

Alder

When drying, it becomes a yellow-red hue with a pinkish tint. The structure is airy and light, often trimmed with walnut or mahogany. Alder items are fragile and soft, do not tolerate mechanical damage. Used to create panels on the wall, cabinets, furniture in the office, arches.

Birch tree

Birch wood has high decorative qualities, it is attributed to hardwood, but it is very fragile. Excellent stain and finish. It has a beautiful heterogeneous structure and patterns, a kind of influx. Color from whitish yellow to brown or pink.

Hornbeam

Or under another white beech. The material is dense, has a whitish-gray color. Fragile, prone to severe cracking, poorly processed, but well stained. It is mainly used as an insert material to simulate ebony or bone.

Poplar

It is rarely used in furniture production. Only massive objects are made from it. Due to its loose structure, the material is subject to mechanical damage.

Ash

Ash wood has a clear pattern of tree rings and a pinkish or yellow tint. The surface of the material is matte, the structure is large, but it is very fragile. Because of this treatment, ash lends itself poorly, when you try to cut it, the annual rings begin to crumble.

To strengthen it, they use the technology of drying over steam, after which the wood is not exposed to the wormhole and the negative effects. Without it, the use of such furniture is impractical.

-

10 rules on how to best repair an apartment for rent

10 rules on how to best repair an apartment for rent

-

Soundproofing and soundproofing of plastic windows

Soundproofing and soundproofing of plastic windows

-

The advantages of houses up to 150 square meters. m

The advantages of houses up to 150 square meters. m

-

What errors lead to water hammer in the heating system and how to avoid them

What errors lead to water hammer in the heating system and how to avoid them

-

12 tips for choosing a good construction team

12 tips for choosing a good construction team

-

How to make repairs once and for a long time

How to make repairs once and for a long time

-

5 reasons to change the wizard without waiting for the repair to finish

5 reasons to change the wizard without waiting for the repair to finish

-

When is it better not to glue paper wallpapers?

When is it better not to glue paper wallpapers?

-

Why you can’t save money by installing infrared heating instead of gas

Why you can’t save money by installing infrared heating instead of gas

-

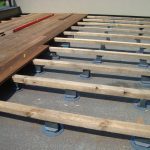

When an adjustable floor is more profitable than a capital screed

When an adjustable floor is more profitable than a capital screed

-

Smart sockets: why call a coffee maker or kettle

Smart sockets: why call a coffee maker or kettle

-

7 mistakes that people usually make when self-organizing home construction

7 mistakes that people usually make when self-organizing home construction

New publications are published daily on our channel in Yandex. Zen

Go to Yandex. Zen