Almost all types of drying oils are made on the basis of oil, into which special substances for quick drying - driers are added. In addition, the composition of drying oil, depending on the brand, may include solvent, white spirit, various kinds of oil products. Drying oil is used to impregnate the surface before applying paint, which saves money, since the paint is several times more expensive than drying oil.

After working with drying oil, there is a problem of cleaning the brush or roller from its residues, since after the drying oil has dried, the tool will become completely unusable. Thus, cleaning the tool after work is necessary as soon as possible.

How to remove residual drying oil from a brush

If the brush is cheap, do not bother with cleaning it, it’s easier and cheaper to buy a new one. But if the brush is of high quality, it makes sense to work on cleaning. To remove drying oil from the brush, first of all, you need to thoroughly wipe it with a clean rag or paper. In this case, you need to try to remove as much residue as possible.

Next, the brush needs to be thoroughly washed in a solvent, white spirit or gasoline, then in a solution of laundry soap, and wiped dry.

Another way to clean the brush is to wipe the tool with a rag or paper after work, then wrap it in a cloth moistened with plenty of solvent and place the brush in a plastic bag. The package itself must be tied tightly. After 2-3 days, the brush can be removed. All residues of drying oil will remain on a napkin. The advantages of this method - the brush does not need to be soaked in a jar, the smell of solvent does not spread throughout the room.

If after a few days the brush will again be needed to work with drying oil, it is not necessary to wash it, it is enough to immerse it in a jar of water - it will not have time to dry and deteriorate.

How to wash a roller from drying oil

After work, old newspapers can be used to remove impregnation residues. Having spread the newspapers in 2-3 layers on a flat surface, you need to roll the roller several times with force.

Next, a solvent, white spirit or gasoline is poured into the roller tray (previously cleaned of paint or drying oil) and the tool is lowered there. Rolled in the tank roller until complete removal of residues of drying oil. After this, the roller must be dried. As soon as the tool is completely dry, it is wrapped with a film or foil for further storage to protect it from dirt and dust.

-

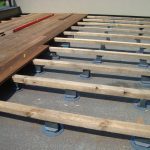

When an adjustable floor is more profitable than a capital screed

When an adjustable floor is more profitable than a capital screed

-

What mistakes are made when the radiator is connected diagonally?

What mistakes are made when the radiator is connected diagonally?

-

What are the consequences of building a site without permission?

What are the consequences of building a site without permission?

-

What errors lead to water hammer in the heating system and how to avoid them

What errors lead to water hammer in the heating system and how to avoid them

-

Why does the grinder work, but the disk does not spin

Why does the grinder work, but the disk does not spin

-

What could cause the cabinet door to bend

What could cause the cabinet door to bend

-

5 reasons to change the wizard without waiting for the repair to finish

5 reasons to change the wizard without waiting for the repair to finish

-

How to cut tiles without dust

How to cut tiles without dust

-

How to cut a fiberboard with a flat edge with a regular grinder

How to cut a fiberboard with a flat edge with a regular grinder

-

Why you should not put aluminum radiators on central heating

Why you should not put aluminum radiators on central heating

-

Why you can not allow for flaws in the installation of roof nodes from corrugated board

Why you can not allow for flaws in the installation of roof nodes from corrugated board

-

What boards can not be used for half-timbered

What boards can not be used for half-timbered

New publications are published daily on our channel in Yandex. Zen

Go to Yandex. Zen