Content

- 1 Water based acrylic

- 2 Bitumen sealants

- 3 Polyurethane Sealants

-

4 Which is better to take

- 4.1 Hybrid Polymer Sealants

- 4.2 Silicone sealants

Sealants may be needed by every person. The main areas of application in everyday life are the repair of joints in repairs and in the bathroom. For such conditions, stable formulations are needed so that after a month of operation, the seam will be securely closed. What types of sealants are better not to take?

Water based acrylic

The main plus of acrylic non-waterproof sealants is their environmental safety, that's usually all. If a buyer in a hardware store purchases this product in the hope of repairing the joints in a bathroom or other room with high humidity, then in the future he will be surprised.

The sealant will crumble in rooms with low temperature and high humidity, and also it will not cope with severely deformed seams. Within a day, under such conditions, the composition will begin to crack, and then fall out of the cavity. Their scope is very limited: work with drywall, baseboards, minor furniture repairs.

Bitumen sealants

Butimny sealants found application in the installation of roofs, foundations, as well as in waterproofing works with materials from concrete, brick, metal. At the same time, such a composition is afraid of high temperature and in the sun will go into liquid form and spread out. Therefore, it is still not recommended to use it for roofing, if there is the possibility of acquiring a different composition.

Polyurethane Sealants

They are most often used for structural sealing of roofs, roof seams, ventilation systems, air conditioners, as well as for sealing joints between walls. The composition has good adhesion to most materials and has high elasticity. But it is extremely unreliable to use it in open areas where the sun's rays fall, since it is destroyed by ultraviolet radiation.

Which is better to take

There are sealants that have many positive qualities and at the same time are universal. These include silicone and hybrid formulations. Their main disadvantage is the high cost.

Hybrid Polymer Sealants

They have high adhesion to many materials, withstand temperature extremes in wide ranges, quickly harden, have an environmentally friendly basis, stored for two years, easily distributed, not oxidized and not destroyed in harsh weather conditions, keep stably high elasticity.

Silicone sealants

Silicone bases are durable and well retain elasticity, resistant to frost and high temperatures, there are several varieties of compounds that expand the scope of silicone sealants.

-

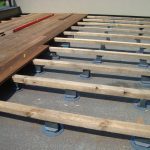

When an adjustable floor is more profitable than a capital screed

When an adjustable floor is more profitable than a capital screed

-

What mistakes are made when the radiator is connected diagonally?

What mistakes are made when the radiator is connected diagonally?

-

What are the consequences of building a site without permission?

What are the consequences of building a site without permission?

-

What errors lead to water hammer in the heating system and how to avoid them

What errors lead to water hammer in the heating system and how to avoid them

-

Why does the grinder work, but the disk does not spin

Why does the grinder work, but the disk does not spin

-

What could cause the cabinet door to bend

What could cause the cabinet door to bend

-

5 reasons to change the wizard without waiting for the repair to finish

5 reasons to change the wizard without waiting for the repair to finish

-

How to cut tiles without dust

How to cut tiles without dust

-

How to cut a fiberboard with a flat edge with a regular grinder

How to cut a fiberboard with a flat edge with a regular grinder

-

Why you should not put aluminum radiators on central heating

Why you should not put aluminum radiators on central heating

-

Why you can not allow for flaws in the installation of roof nodes from corrugated board

Why you can not allow for flaws in the installation of roof nodes from corrugated board

-

What boards can not be used for half-timbered

What boards can not be used for half-timbered

New publications are published daily on our channel in Yandex. Zen

Go to Yandex. Zen