A newly minted welder who recently acquired a corresponding inverter type apparatus, as well as necessary accessories like masks and gloves, seeks to take up complex work as soon as possible or repeat what they saw on the Internet master classes. Someone wants to fill their hand as soon as possible in order to earn money on welding works in the future.

In all these cases, the craftsmen are in a hurry to start practice, not having figured out all the key rules for handling welding. In fact, this leads to a number of gross errors.

For some reason, many believe that the issue of safety in handling welding refers exclusively to the handling of equipment. However, improper work is no less dangerous for all the wiring in the house. To protect yourself enough, one mask is not enough, you need to take care of closed clothing made of thick durable material. It is impossible to do without special gloves called gaiters; ordinary household gloves will be relevant until the first burn from welding spatter, which, by the way, will heal for a very long time.

As for the welding process itself, it is best to avoid using carrying. The longer it is, the less is the power of the apparatus, which inevitably can affect the quality of the seam, especially if delicate work is required. If you cannot do without carrying it, it is strongly recommended that you unwind it completely.

Rarely, but still there are cases when craftsmen try to work with raw electrodes, they this is not necessarily wet as after rain, but, for example, after storage in a rather humid indoors. Such an electrode can behave completely unpredictably during operation. The electrodes must not only be dried, but also properly calcined. This is especially important for beginners, because it is not so difficult to work with an experienced master in non-calcined electrodes.

Even after a careful study of all the manuals, master classes and welding tips, a beginner can get a sloppy uneven seam. Often the reason for this is an improperly selected electrode. It is ideal to begin acquaintance with welding with a rutile copy of the MP3-C type, ANO-21 is also suitable. Using old stocks of almost Soviet times, you can get any result you want, but not a high-quality beautiful seam.

Poor-quality products of novice welders are often one of the first work experiences. Therefore, in order for various metal structures and fences performed by a beginner to look decent, you need to properly fill your hand. To do this, it is enough to stock up on a thick metal plate, strip it to a metallic sheen with a grinder and begin to impose the rollers by welding. It happens that some craftsmen, having put rollers and creating a decent seam, forget to knock slag. In other cases, they do it too hard, as a result, pieces of hot slag can fly off to exposed skin, or even to the eye. Only after the horizontal seams are well worked out, you can proceed to the vertical. Some beginners manage to start laying a vertical seam not from bottom to top, but from top to bottom. When the developed methods of vertical welding, you can go to the ceiling option. Only after the appearance of decent skills in these three types of work can you start some serious products.

-

10 rules on how to best repair an apartment for rent

10 rules on how to best repair an apartment for rent

-

Soundproofing and soundproofing of plastic windows

Soundproofing and soundproofing of plastic windows

-

The advantages of houses up to 150 square meters. m

The advantages of houses up to 150 square meters. m

-

What errors lead to water hammer in the heating system and how to avoid them

What errors lead to water hammer in the heating system and how to avoid them

-

12 tips for choosing a good construction team

12 tips for choosing a good construction team

-

How to make repairs once and for a long time

How to make repairs once and for a long time

-

5 reasons to change the wizard without waiting for the repair to finish

5 reasons to change the wizard without waiting for the repair to finish

-

When is it better not to glue paper wallpapers?

When is it better not to glue paper wallpapers?

-

Why you can’t save money by installing infrared heating instead of gas

Why you can’t save money by installing infrared heating instead of gas

-

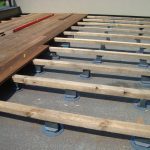

When an adjustable floor is more profitable than a capital screed

When an adjustable floor is more profitable than a capital screed

-

Smart sockets: why call a coffee maker or kettle

Smart sockets: why call a coffee maker or kettle

-

7 mistakes that people usually make when self-organizing home construction

7 mistakes that people usually make when self-organizing home construction

New publications are published daily on our channel in Yandex. Zen

Go to Yandex. Zen