Content

- 1 The most common mistakes

- 2 Excessive water in solution

- 3 Incorrect installation of guide beacons

- 4 Mistakes in the manufacture of screed reinforcement

- 5 Improper maintenance of the finished coating

When carrying out work related to cement mixtures, very often there are problems of partial or complete cracking of the screed. The quality of the poured rough floor is influenced by many factors, but it is the formation of cracks that occurs due to common mistakes made by novice craftsmen.

The most common mistakes

There are four types of them:

- The prepared cement mortar has too much water;

- Errors when installing guide beacons;

- Errors in the implementation of reinforcement;

- Improper maintenance of the finished coating.

Consider all types of errors more specifically and in order.

Excessive water in solution

High-quality cement-sand mortar has a very thick consistency. Working with him is pretty hard. And many aspiring masters strive to ease their work by adding extra water to the finished solution. Of course, it will give greater elasticity to the mixture and it is much easier to work with it.

This approach to business is considered extremely wrong. Excessive moisture in the solution significantly reduces the strength of the future screed. And even if no cracks form on it, it will continue to produce a lot of dust.

Incorrect installation of guide beacons

In no case do not install beacons on quickly-drying materials. These include gypsum and other solutions based on it. Due to the different density of materials, cracks will form in the places where the beacons are located, which, in the future, will lead to the destruction of the entire subfloor.

Mistakes in the manufacture of screed reinforcement

Reinforcement of the subfloor is necessary in compliance with certain standards. The formation of voids is highly undesirable. If you violate these requirements, then the screed will certainly begin to crack and collapse.

Improper maintenance of the finished coating

Many novice masters do not attach importance to proper care for the screed screed. They believe that she herself should simply dry and everything is ready. The poured base is required to be shed well with water for 3-4 days. Moreover, it must be covered with plastic wrap for 10 days. And only after passing a month, the floor will be completely ready.

Observe all of the above nuances and do not make the above errors. And then, you get an even screed, without any cracks.

-

What boards can not be used for half-timbered

What boards can not be used for half-timbered

-

Why does the grinder work, but the disk does not spin

Why does the grinder work, but the disk does not spin

-

Features of the installation of half-timbered columns

Features of the installation of half-timbered columns

-

How to make a rectangular cutout in ceramic tiles

How to make a rectangular cutout in ceramic tiles

-

How to restore knife marks on a countertop

How to restore knife marks on a countertop

-

What mistakes are made when the radiator is connected diagonally?

What mistakes are made when the radiator is connected diagonally?

-

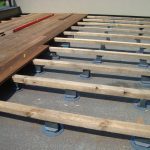

When an adjustable floor is more profitable than a capital screed

When an adjustable floor is more profitable than a capital screed

-

What primers are not suitable for application under fiberboard

What primers are not suitable for application under fiberboard

-

What installation errors lead to the leakage of the polycarbonate canopy

What installation errors lead to the leakage of the polycarbonate canopy

-

When you need to install heating radiators not under the window

When you need to install heating radiators not under the window

-

How to paint from spray can without smudges

How to paint from spray can without smudges

-

How to cut glued tiles on a wall

How to cut glued tiles on a wall

New publications are published daily on our channel in Yandex. Zen

Go to Yandex. Zen