Polycarbonate is a modern building material, widely used for construction, canopies, greenhouses, peaks over the front doors and arbors. This material has high strength and good flexibility. Polycarbonate is widely used due to precisely these properties, as well as due to the ease of processing and low cost.

Building structures constructed using polycarbonate are generally curved. Therefore, in addition to cutting it often has to be bent. However, there is nothing complicated in this, the main thing is to observe the technology.

Unlike plexiglass, polycarbonate can be bent without any heating and special tools. For this, it is only necessary to observe the permissible bending angle. It is usually indicated on the packaging. The angle depends on the length of the polycarbonate sheet and its thickness. The greater the length, the greater the angle you can bend the sheet. Increasing the thickness of the material reduces the angle of bending. The size of the muscular force exerted on polycarbonate for bending also depends on the length of the sheet.

It is important to remember that cellular polycarbonate can be bent only along the honeycomb. Bending across the honeycomb will lead to the inevitable destruction of the material. The same result can be achieved by heating polycarbonate in an attempt to increase the permissible bending angle. Bending it at any angle, like a sheet of metal, will not work.

When erecting greenhouses, sheds or peaks above the front door, the radius of the arched arches should not exceed the permissible bending angle of polycarbonate. The sheets are cut to the desired length, which is determined by measuring the arch of the arch with a construction tape. The cavities of the honeycombs of the cut sheet are immediately cleaned of chips that have fallen into them. Then polycarbonate is applied to the arches of the arch and, using self-tapping screws with thermowells, fix one of its edges. Next, pressing the sheet with your hand to the arc, sequentially attach it to its entire length.

Parallel connection of bent sheets should be carried out using a special joint profile. Sheets are inserted into them with a gap of several millimeters. Compliance with such a simple technology will prevent the destruction of polycarbonate at the joints and bends.

Monolithic polycarbonate is bent, holding the sheet in a vice. In order not to damage brittle material, use wooden slats, between which they lay polycarbonate before fixing in a vice. Then, applying a small force, the sheet is gradually bent to the desired angle.

-

10 rules on how to best repair an apartment for rent

10 rules on how to best repair an apartment for rent

-

Soundproofing and soundproofing of plastic windows

Soundproofing and soundproofing of plastic windows

-

The advantages of houses up to 150 square meters. m

The advantages of houses up to 150 square meters. m

-

What errors lead to water hammer in the heating system and how to avoid them

What errors lead to water hammer in the heating system and how to avoid them

-

12 tips for choosing a good construction team

12 tips for choosing a good construction team

-

How to make repairs once and for a long time

How to make repairs once and for a long time

-

5 reasons to change the wizard without waiting for the repair to finish

5 reasons to change the wizard without waiting for the repair to finish

-

When is it better not to glue paper wallpapers?

When is it better not to glue paper wallpapers?

-

Why you can’t save money by installing infrared heating instead of gas

Why you can’t save money by installing infrared heating instead of gas

-

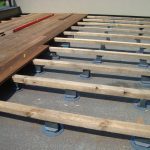

When an adjustable floor is more profitable than a capital screed

When an adjustable floor is more profitable than a capital screed

-

Smart sockets: why call a coffee maker or kettle

Smart sockets: why call a coffee maker or kettle

-

7 mistakes that people usually make when self-organizing home construction

7 mistakes that people usually make when self-organizing home construction

New publications are published daily on our channel in Yandex. Zen

Go to Yandex. Zen