More and more people when choosing a finishing material for the floor prefer the laminate. Such a noticeable demand for laminate flooring is quite justified, because it has an affordable price, just fits and can boast of excellent performance properties.

Laminate does not require much attention in the care, which also like customers. In order to tidy up the laminate, you just need to polish it. Thus, the surface of the flooring becomes shiny. Moreover, as a result, it will be possible to save the laminate longer.

Laminate polishing costs only three times a year. In this regard, it is important to choose a high-quality polish that is designed for the laminate to perform these works. Parquet polish is not suitable for laminate flooring. This should not be forgotten. This is explained by the fact that the laminate has a protective film on the surface. Therefore, wax products negatively affect the laminate. As a result, ugly spots appear on it.

Types of polishing agents

It is possible to get polishes today in the form of sprays, mastics and soluble products. Soluble polish is used for wet cleaning. It dissolves in a certain amount of water, after which the floor is washed well.

Polishes in the form of sprays and mastics are applied directly to the surface and thoroughly rubbed. Such products protect the coating from external factors for longer.

Sanding the laminate, is it worth it

In the event that scratches and chips appeared on the laminate during operation, then they can be repaired using a special paste or putty. You must first select the right color shade. These putties will be obtained in the store where the laminate was previously bought. After prolonged use, deep defects may appear on the laminate. To seal them, use PVA glue. It is impossible to grind a surface of a laminate. Thus, it is possible to damage the structure of the material. As a result, the floor base will soon begin to deteriorate.

In order to tidy up the laminate, it is necessary to put on it the repair composition, which was mentioned earlier in the article, and then cover the laminate with varnish. This work is allowed to be carried out using a roller or brush. The application of varnish on the laminate should be done with gentle movements with a thin layer. To get a good result, it is worth applying varnish on the floor surface in three layers with preliminary drying of each of them.

-

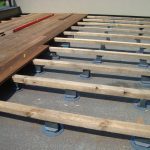

When an adjustable floor is more profitable than a capital screed

When an adjustable floor is more profitable than a capital screed

-

What mistakes are made when the radiator is connected diagonally?

What mistakes are made when the radiator is connected diagonally?

-

What are the consequences of building a site without permission?

What are the consequences of building a site without permission?

-

What errors lead to water hammer in the heating system and how to avoid them

What errors lead to water hammer in the heating system and how to avoid them

-

Why does the grinder work, but the disk does not spin

Why does the grinder work, but the disk does not spin

-

What could cause the cabinet door to bend

What could cause the cabinet door to bend

-

5 reasons to change the wizard without waiting for the repair to finish

5 reasons to change the wizard without waiting for the repair to finish

-

How to cut tiles without dust

How to cut tiles without dust

-

How to cut a fiberboard with a flat edge with a regular grinder

How to cut a fiberboard with a flat edge with a regular grinder

-

Why you should not put aluminum radiators on central heating

Why you should not put aluminum radiators on central heating

-

Why you can not allow for flaws in the installation of roof nodes from corrugated board

Why you can not allow for flaws in the installation of roof nodes from corrugated board

-

What boards can not be used for half-timbered

What boards can not be used for half-timbered

New publications are published daily on our channel in Yandex. Zen

Go to Yandex. Zen