"Bulgarian" is a truly universal thing, a universal assistant for any master. However, over time, like any electric tool, the grinder may break or completely fail.

Since the tool does not differ in particular complexity, and the device of all the grinders is almost the same, the breakdowns are similar.

To identify the causes of a malfunction, you need to familiarize yourself with the device device at least theoretically. The general arrangement of all devices is as follows:

- Rotating anchor;

- Collectors anchors with windings, or, as they are also called, lamellas;

- Stator - fixed part of the engine;

- Graphite brushes - conductors of electricity to collectors;

- Gear - a device for transmitting torque from the armature to the cutting element of the tool.

Possible malfunctions: how to fix them

The most common problem is brush wear. True, this is hardly a malfunction, rather, the need to replace consumables. Most often, plugs that cover the brushes are located on both sides of the housing. Some models of grinders are arranged so that in order to get to the brushes, you have to disassemble the case. However, in most cases, brush replacement is done in a few minutes.

Since the tool has to work in different positions, very often the power cable breaks, most often at the base. For repairs, you will have to disassemble the case and connect or solder the cable inside the tool.

Sometimes metal dust builds up inside the case. Because of this, the turns in the windings of the armature or stator can be shorted. Such malfunctions manifest themselves in the form of an unpleasant odor, the case begins to warm up, the windings may darken. If there are no external signs of winding closure, they are detected with a multimeter. The resistance on all windings should be approximately the same. A tool with such a malfunction should be immediately sent to a workshop for diagnosis and repair.

Sometimes the contacts of the start button burn out. The problem is eliminated by replacing it, something to solder and screw in this case is not recommended.

The grinder works, but the disk does not spin - you should immediately disconnect the tool from the network and do not try to run it anymore, since it is possible to further damage the case and working parts. The reason for such a breakdown is the lack of adhesion between the gears or the failure of one of the shafts. This is one of the most serious damage that can happen to a grinder.

Tool transfer consists of two gears. Even if only one is damaged, both are changed. If you are very lucky, then the disk may not spin just because of the weakened gear mounting nut. If the anchor shaft is cut off, you will have to change the entire anchor. Such damage can be seen immediately when opening the gearbox (you just need to unscrew a few bolts).

To prevent such breakdowns, you should carefully handle the tool, do not press on the disk, and regularly lubricate the gears in the gearbox.

-

What boards can not be used for half-timbered

What boards can not be used for half-timbered

-

What is the advantage of a nichrome plexiglas cutter?

What is the advantage of a nichrome plexiglas cutter?

-

Features of the installation of half-timbered columns

Features of the installation of half-timbered columns

-

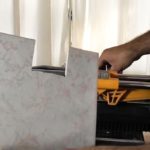

How to make a rectangular cutout in ceramic tiles

How to make a rectangular cutout in ceramic tiles

-

What to do if wallpaper glue dries too fast

What to do if wallpaper glue dries too fast

-

What mistakes are made when the radiator is connected diagonally?

What mistakes are made when the radiator is connected diagonally?

-

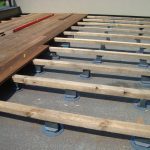

When an adjustable floor is more profitable than a capital screed

When an adjustable floor is more profitable than a capital screed

-

How to paint from spray can without smudges

How to paint from spray can without smudges

-

What primers are not suitable for application under fiberboard

What primers are not suitable for application under fiberboard

-

How to cut glued tiles on a wall

How to cut glued tiles on a wall

-

When you need to install heating radiators not under the window

When you need to install heating radiators not under the window

-

How to dissolve the clypeus along its length

How to dissolve the clypeus along its length

New publications are published daily on our channel in Yandex. Zen

Go to Yandex. Zen