Of course, when choosing a material, one should take into account the weather conditions of the region and the condition of the soil, so that errors in the calculations do not reduce all efforts to zero. Materials for quick assembly of a factory-made house must meet the following criteria:

- Quality assurance;

- Simplicity and manufacturability of installation;

- Strictly specified geometry;

- Availability.

Handicraft materials in this case should not be used, since they will not give the required quality.

What to choose for walls and foundations

A tree has proven itself for a good construction of a house using frame technology. Working with ready-made panels is simple and fast; at least large equipment is used. You can put a wooden frame together with an assistant and even one, which, of course, is more difficult. It is important that the tree is affordable.

If you involve construction companies, you can expose the box from large-format factory-made panels.

Building a stone house is the fastest way from large blocks that have a clear geometry and can easily be processed directly at the construction site. For example, a house made of aerated concrete blocks can actually be built during the summer season if a team of two or three people works. Such blocks are easy and quick to stack.

The speed of building a house will increase significantly if there is already electricity and water on the site.

When choosing the technology for pouring the foundation, experts recommend the use of fixed formwork. Concrete is poured into a foam box, which also serves as a heater.

A warm frame house with an area of 60 square meters with a fine finish can be built and one in 3 months. The plus is that the construction is really possible all year round, “wet” processes are minimized, and the proven technology gives a guarantee of high speed.

The foundation for the frame house is usually selected tape shallow, and formwork boards after removal can be used to build the frame and racks.

The house from SIP panels is assembled as a designer, which allows to reduce the time of work. Before the onset of cold weather, you need to have time to enter the house, and then continue decorating and landscaping. The main thing is to build a box with initial communications and amenities. A frame house on a pile-screw foundation can be ready to receive residents in a month. However, the process must be constantly monitored so as not to miss important details, which then have to be redone.

You can quickly build a small house with an area of up to 150 squares. Moreover, the less different architectural excesses and decorations in it, the better. It is desirable to choose the simplest form of the house and roof, and the basement is not needed at all.

-

What are the consequences of building a site without permission?

What are the consequences of building a site without permission?

-

How to dock a carpet so that it does not go in waves

How to dock a carpet so that it does not go in waves

-

Why in the homes of SIP panels can not forget about good ventilation

Why in the homes of SIP panels can not forget about good ventilation

-

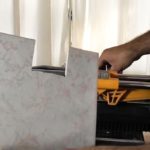

How to make a rectangular cutout in ceramic tiles

How to make a rectangular cutout in ceramic tiles

-

How to cut glued tiles on a wall

How to cut glued tiles on a wall

-

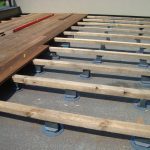

When an adjustable floor is more profitable than a capital screed

When an adjustable floor is more profitable than a capital screed

-

Why you can’t save money by installing infrared heating instead of gas

Why you can’t save money by installing infrared heating instead of gas

-

What help should be provided for poisoning with paint fumes

What help should be provided for poisoning with paint fumes

-

What to do if the last heating battery does not heat

What to do if the last heating battery does not heat

-

What installation errors lead to the leakage of the polycarbonate canopy

What installation errors lead to the leakage of the polycarbonate canopy

-

What yellow spots appear on the wallpaper after gluing

What yellow spots appear on the wallpaper after gluing

-

What primers are not suitable for application under fiberboard

What primers are not suitable for application under fiberboard

New publications are published daily on our channel in Yandex. Zen

Go to Yandex. Zen