Tile is a unique finishing material due to its aesthetic appearance, ease of installation, ease of maintenance and relatively low cost. Quite often, it becomes necessary to drill a hole in this type of coating for installing accessories, mounting shelves, sockets or switches.

Tile is a unique finishing material due to its aesthetic appearance, ease of installation, ease of maintenance and relatively low cost. Quite often, it becomes necessary to drill a hole in this type of coating for installing accessories, mounting shelves, sockets or switches.

At the same time, novice craftsmen often have a question about how to drill ceramic tiles - the material, especially with a glazed surface, is very fragile and prone to chips and cracks. In addition, it has a strong abrasive effect on the tools used.

Attention! Earned on our website kitchen designer. You can familiarize yourself with it and design your dream kitchen for free! May also come in handy wardrobes designer.

If there is no opportunity or desire to contact professional repairmen, then the technique can be mastered independently.

How to properly drill a tile: preparatory work

Studying the question of how to properly drill a tile, first you should practice on production waste or materials remaining after wall cladding. It is unlikely that it will be possible to successfully drill the tile the first time.

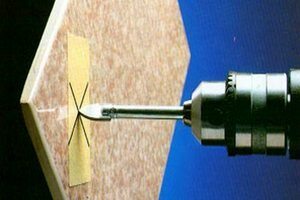

It is important to accurately mark the area of the wall to be treated. To do this, use a piece of masking tape. Not every marker leaves a mark on the tile, and most of the marks made can be "smeared" with a careless movement. Part of the scotch tape is glued to the treated area, and marking is already done on it.

The use of scotch tape also makes drilling easier - when working with a core, the possibility of damage to the tile and the formation of chips remains.

The best option to drill the tile would be to carry out the specified work before laying it. Before this, you should carefully prepare the workplace: equip a level place of sufficient size, on which to lay a piece of material that does not interfere with the passage of the drill. As such materials can be used:

- tree;

- plywood;

- drywall.

It is necessary to take care of the availability of all the necessary tools in advance before starting work.

Hole drilling: tools required

It is very undesirable to use tools with an impact type of work for drilling such a tile - they can cause irreparable damage to the treated surface.

The following tools are used to drill the tile:

- an electric drill or a powerful screwdriver: it is important to ensure that when using these mechanisms, the number of drill revolutions increases smoothly;

- hand drill: in order to make small holes in a ceramic tile, a manual mechanism is enough, and the number of revolutions in it is convenient to adjust independently;

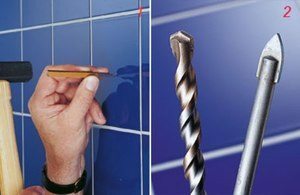

- standard carbide tipped drills: these tools are recommended to be used after passing through the hardest top layer of the tile;

- lance drills for working with tiles - most convenient for creating small holes for dowels;

- drills with a hard layer with acute-angled sharpening - the most effective for drilling tiles, enough for a fairly large amount of work;

- diamond core drills: used mostly by professionals; it is convenient to operate with them when creating a large diameter of holes; have a special hole for the removal of destroyed tile remnants;

- drill-"ballerina": well suited for performing infrequent work by novice craftsmen, used for drilling holes with a diameter of three to nine centimeters;

- conductors: used to prevent the drill from playing, for greater accuracy; are mounted on the wall with the help of special suction cups and do not allow the tool to "jump off" from the place of work;

- water blowers: used when the drill is overheated to supply coolant (water) to the drilling site;

- protective goggles and gloves.

Drilling: general recommendations

To carry out drilling work, do not use too high revolutions: it is sufficient if the tool rotates at a speed of 100 to 400 revolutions. The exact number of rotations desired depends on the type of material and its coating.

Do not create too much pressure on the working tool - this can lead to the destruction of the tile and overheating.

Do not create too much pressure on the working tool - this can lead to the destruction of the tile and overheating.

In the absence of water blowers and operation on a horizontal surface, the local cooling method can be applied. To do this, a plasticine funnel is fashioned around the work area, which is filled with cold water.

To properly drill the surface, the drill bit or screwdriver should always be positioned perpendicular to the work area. Without special tools, you have to monitor this parameter yourself.

You should never neglect protective equipment - work on drilling ceramic tiles is always accompanied by the scattering of small fragments, which are especially dangerous if they get into the eyes.

How to drill a small hole

Drilling tiles on the walls is the most common type of work under consideration. In the process of using bathrooms or sanitary rooms, it is often necessary to hang a new accessory on an already tiled surface. For such purposes, holes are created in the walls of a small diameter, into which dowels are placed.

Before drilling, it is important to apply the correct markings on the wall: it is not desirable that the hole placed closer than 15 mm to the edge of the tile - there is a high probability of chips and other damage cover.

The dimensions should exceed the diameter of the plug for the dowel by 1-2 mm. After passing through the thickness of the tile, it is advisable to change the drill to a conventional wall punching tool, so as not to blunt a higher-quality part. In the process of work, you should carefully monitor that the drill does not go into a slope and does not damage the tiles. After that, you should carefully hammer the dowel into the wall.

How to Drill Tile: Making Large Holes

The method of creating large holes, which has long been used by repairmen, is the most time consuming. With it, small holes are first drilled around the entire circumference of the required size. Then the surface is "finalized" using screwdrivers, files and hammers. Possible irregularities are cleaned with sandpaper.

The method of creating large holes, which has long been used by repairmen, is the most time consuming. With it, small holes are first drilled around the entire circumference of the required size. Then the surface is "finalized" using screwdrivers, files and hammers. Possible irregularities are cleaned with sandpaper.

The easiest way is to use crowns instead of drills. The work with the use of conductors is much easier. The latter are attached to the wall with a suction cup; the master only needs to carefully drill a hole of the required diameter.

The method of using the "ballerina" drill cannot be called a simple one. At the beginning of the work, a small hole is drilled in the center of the circle, into which the centering drill of the tool is inserted. It is important to remember when setting the ballerina's movable leg that in this case the radius is regulated, not the diameter (that is, the dimensions should be halved). The next step is to firmly fasten the locking screw so that the tool does not move.

When using this tool, you should maintain low turns and smooth pressure on the surface of the tile. It is also necessary to ensure that the same drilling depth is maintained in all parts of the circle. As a rule, using a "ballerina" requires finishing the edges of the hole with sandpaper.

For all the seeming complexity of this type of work, even a novice master can drill such a tile. You just have to adhere to all the rules and use quality tools during the repair.

Video: making a hole in the wall with ceramic tiles for sockets

average rating 0 / 5. Number of ratings: 0

No ratings yet. Be the first to rate.