Marble stains are mesmerizing. But marble is soft, which is why it is rare in the kitchen. Hard granite, but difficult to work with. Concrete is an artificial stone, it is lighter, more varied in color and pattern. An acrylic or epoxy conglomerate countertop would compensate for the disadvantages of stone slabs if not for the price. Casting yourself out of concrete, feeling like a sculptor - why not an idea? Having plunged into technological tricks, it turns out that concrete does not conceal any particular difficulties.

Features of concrete in the manufacture of kitchen furniture

Desired properties of furniture concrete:

Attention! Earned on our website kitchen designer. You can familiarize yourself with it and design your dream kitchen for free! May also come in handy wardrobes designer.

- does not crack at low thickness, that is, it has sufficient toughness,

- does not overload furniture supports,

- absorbs a minimum of heat,

- the plate must be highly decorative, fit into the interior,

- amenable to grinding, polishing, and therefore filling granules are selected with a hardness identical to concrete,

- the mass is created with a homogeneous consistency, but thick, plastic - in such a way as to fill the mold manually, without filling (the used construction term "casting" is not entirely correct here),

- as a result - a solid plate up to 40 mm thick, this is the main requirement.

The listed properties are achieved by adding washed quartz sand, marble chips, plasticizers, broken glass, stable (dry / pasty) dyes to the cement (grade not lower than 400).

Interesting: white grout for tile joints is white cement M500, which has all the properties of a molding material.

The chaotic mosaic is interesting. Pieces of polished onyx, marble are placed at the very bottom of the mold, the gaps are filled with a mixture of sand, cement, and crumbs. Fragments at the bottom should not be polished - for bonding. The thinner the mosaic elements, the stronger the monolith.

Design and creation of a drawing

A product that is longer than 4 m must be reinforced. Depending on the method of reinforcement, concrete countertops are subdivided into:

- with chipboard filling,

- reinforced with metal,

- fiberglass.

Reinforcement methods are as follows:

- From channels, corners, triangular brackets up to 60 cm are welded (the width may be greater), they are fastened with a step of 0.5 m to the wall along the level with the help of dowels. This provides access to the floor that has not yet been equipped. The level from the concrete floor screed is h = 25 (floor) +850 (kitchen cabinets) - 30 - 30 = 815 (mm), the first 30 mm is the thickness of the concrete countertop, the second 30 mm is the moisture-resistant plywood of the base. The wall is grooved until a groove is formed. The groove is filled with strips of polystyrene (the plate will “play” in size, heating up and then cooling down). The board of the countertop is mounted on a plywood sheet. Pour in. Replacement of plywood - two sheets of fiberboard fastened together.

- A reinforcing welded grating made of a metal bar is placed in the pouring tray between the concrete layers, having previously treated the inset structure with an anti-corrosion compound. The rods do not reach the 5 cm slab contour.

- With a total tabletop height of 35 mm, the first layer of fiberglass is laid after pouring 15 mm of concrete, the second after 20 mm, by pressing. The third layer is applied on top.

But the most advanced reinforcement is chipboard-filling: with it, the tabletop weighs less, the plate is drilled, it becomes possible to reduce the thickness and reduce the cost. An important point - the fiberboard sheet itself is used again as an insert after the template is made. Paradoxically, combining fiberboard with concrete must be prevented (the tensile coefficient of the materials is different). The recessed sheet has the value of a substrate, it is impregnated with linseed oil even before it comes into contact with cement.

It is safer to mount and transport a “sandwich” of both layers. So that the fiberboard does not fall out of the nest, it is wound with tape, the last stage is glued with mounting glue.

A combination of different reinforcement methods is always permissible. Welded lines are used to reinforce around large holes. It is important to prepare the reinforcement inserts in advance because the casting process takes only 50 minutes. After the first setting, the concrete cannot be moved and moved: the structure will be broken. Complete hardening occurs after 2 weeks.

Drawing, template

Working with the plan, you need to decide where the hob will be, where is the sink. It is important to use the possibilities of the cast tabletop to the maximum: any configuration allows place the sink in the protruding “crest” of the wave, the hob can stand across, not along walls. Perhaps you need to abandon the semicircular break of the table and give the edges a kind of avant-garde shape.

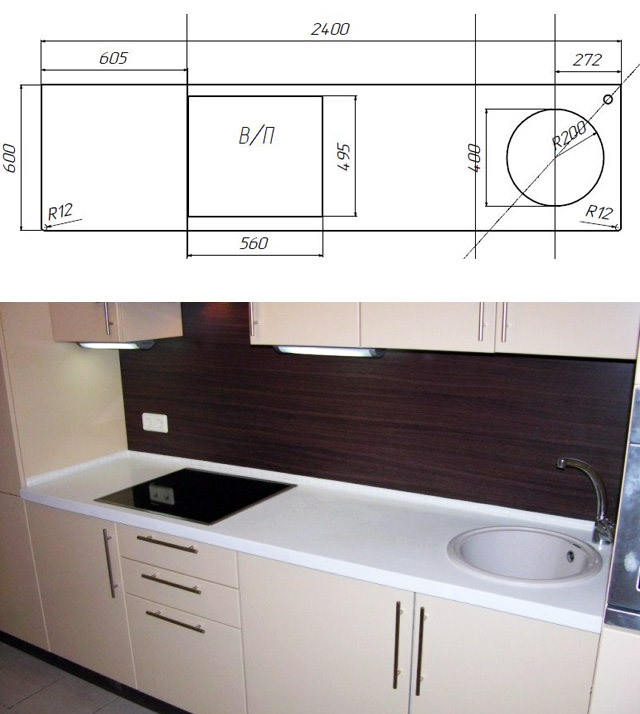

Original, remember the modularity of the sideboards, upper cabinets. Having measured the wall, they are looking for options in a grid with a step of 20, 30 cm (scale 1:10), inscribing the hob, oven, hood and taking into account that all the furniture will be covered with the same type of doors, flanges - it should look complete, rhythmically.

Two strips of fiberboard set the value of each specific angle in place, fasten the sheets with a glue gun. Then they bring the sheet to the wall, mark future slots on the fiberboard, protrusions for niches, wall turns, sink contours, electric stove, etc. The starting / ending points of the readouts are not set on the plaster - at a distance of 18 mm from the corners (the size of the thickness of the ceramic apron). You also need to take into account that the real angles of the premises differ from 90 degrees.

Experimenting with color

- Determine whether the table top should be light or dark, perhaps gray?

- Reddish, beige, yellowish or cold.

- The incoming blotches are dark on white. Then from what? Ditto for the opposite effect.

Cut off the milk carton, mix the sample by adding broken brown, green, transparent glass, mica, amber along with the dye. The result is corrected.

Regardless of the additives, the concrete base is classic:

- for casting - cement + river (preferably quartz) sand, ratio 1: 4;

- for modeling - the ratio is 1: 3.

Water is added gradually. The density of the first solution is oil. The density of the second is plasticine. The mold is poured first. The second is kneaded for frame concrete.

During the creation of the sample, the ratio of the ingredients is recorded. The main components are common. To improve the plasticity of the mass, it is recommended to add 150 g of washing powder (solution) to 25 kg of cement. There is a universal concrete plasticizer on the market that improves toughness and plasticity.

Form preparation

Chipboard is placed on a solid table, exceeding the contours of the product by 20 cm. The surface is covered with PVC, with a sheet of thicknesses. 2 mm (options - polystyrene, fiberboard). With strips of chipboard (planed beams) on the drawn contours, spread the board lubricated with silicone, fix it with self-tapping screws, clamping it so that the silicone goes beyond the gap. The excess is erased. To form a facet at the junction of the substrate and the bead, a hose with a diameter of 1 cm is fixed, filling the gap of the hose and flat surfaces with window putty.

You can set the facet configuration yourself. To do this, a wooden plank is thinned at the edge “under the shoulder blade”, the profile is cut with a jigsaw. Made from hardwood, water-repellent properties are obtained from impregnation with sunflower oil. With such an abacus, the window putty is distributed with broaches.

In order to avoid leaving the board from the perpendicular, it is reinforced with stiffening ribs from pieces of plywood, chipboard.

The circles are laid out with thick plastic, also fastening them on the “ribs”, drilling “in the sweep”. Sharp bends are made of strips of thick plastic of the same height as the side, heated to 160 degrees. The work is carried out, protecting hands with thermal gloves. A tungsten filament behind a metal box, covered with an even larger box - a simplified design of the heater. Plastics choose refractory.

Places of pipe inlets, cutouts are laid with plastic plugs from shampoos, from old cans, polypropylene pipes, etc., fastened with a glue gun. Level-checked sides are sprayed with liquid wax (soap bar, as an option) from a household spray. The dried surfaces are protected from adhesion to concrete 2-3 times.

Fill the table

The concrete mixer is filled with cement - 60% of the volume, sand - 10%, solid fractions - 29.5%. Water is only 0.5%. Check the viscosity, transfer by hand or in bulk from buckets. The mobile concrete is spread with a trowel. Plasticine is trampled down with palms, small blocks of wood. Align on the upper edge with a bar (or a building level of the "knife" type). Aligned, cover without gaps with plastic wrap.

The thick mass (for "stucco" tables) is laid by a team of manufacturers: in 50 minutes you need to have time to lay out, compact.

Laying decorative elements and inserting fasteners

The location of the grooves for the dowels, metal corners, if any, are set in advance, marked on the template. Then the template is attached to a wooden frame that coincides with the contour board. The template sheet is drilled (cut through) at the marks.

The grooves for the dowels are formed by the dowels themselves, and the corners are welded onto pieces of a reinforcing mesh. Moving the corners along the non-frozen mass, they find a match with the template, pour it on top.

The pre-cast molded brackets with protruding reinforcement are welded to the reinforcing mesh. The inserts protruding beyond the countertop are aligned with angles and level according to the marks indicated on the template.

Grinding, polishing

After 2 weeks, the countertop is opened, moistened several times, dried - to ensure the end of the chemical processes. A dry slab is ground first from the bottom. Then it is turned over, moistened, dried and polished with a P 80 grinder. Increase the grain size by 50 values, continue grinding until a “mirror” surface is obtained. The end of the process is P 500 emery with the addition of water. The grinder must have guaranteed moisture protection. In inaccessible places, a round stick with a skin fixed on it, a wooden block is used.

Restoration of an old concrete countertop

Primer for concrete is applied to the old concrete countertop and dried. Distribute with a spatula a composition similar to the previous one. Cracks are filled with a knife, awl, trowel. The dried surface is sanded and water-repellent with liquid wax that polishes wooden surfaces (like Pronto).

Video: how to make a concrete countertop, a kitchen sink with your own hands - instructions

Above, we looked at how to make a concrete countertop, below - instructions for making a sink with your own hands.

Wide planes are comfortable, visually expanding the space. Arrangement of the kitchen with ordinary rectangular countertops can be achieved by cutting out chipboard, MDF plates. Is it worth bothering with the casting process if only rectangular shapes are planned? Also, in a small kitchen it is impossible to appreciate a spectacular wavy line. You need at least 4–5 meters of a free wall.

average rating 0 / 5. Number of ratings: 0

No ratings yet. Be the first to rate.