The advent of casting technology for tubular blanks for systems heating served as an impetus for the search for new types of materials based on polypropylene. As a result, one of the most successful solutions was a polypropylene pipe reinforced with fiberglass. Developers managed to retain the advantages of using polypropylene and partially compensate for the disadvantages inherent in the polymer matrix.

The content of the article:

-

What advantages does

- Why fiberglass reinforced blanks outperform aluminum foil blanks

-

What is characteristic of a polypropylene pipe reinforced with fiberglass

- Safety

- Soldering Reliability

-

How to choose for heating

- Marking

- Manufacturers and color

- Mounting Features

What advantages does

Usually, when planning a heating or water supply system, a prudent owner tries to “squeeze” the estimate to a minimum. Hence the desire to save money on replacing pipes recommended by experts with a cheaper option.

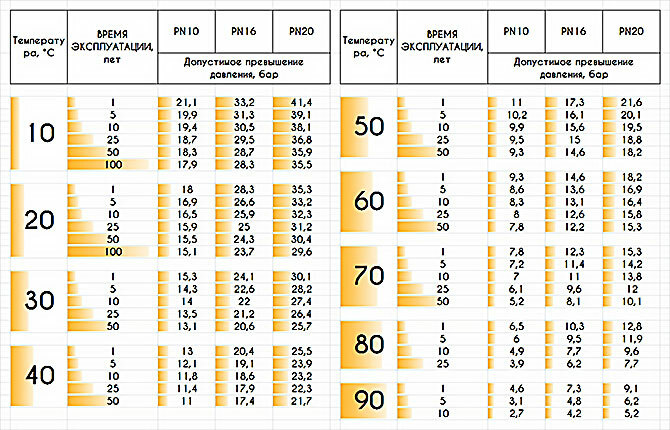

For example, instead of the standard scheme for using fiberglass reinforced polypropylene pipes for heating (and for water supply), they put the usual PN30 at a working pressure of 30 bar. The motivation for this decision is that the 30th pipe has thicker walls, which means a greater margin of safety. But this is only for cold and hot water supply. In this case, the temperature of hot water does not exceed 60 ℃, so even the usual one, PN25, without a reinforced underlayer is sufficient.

For heating, this approach can turn into serious problems. Therefore, only reinforced polypropylene pipes containing fiberglass are used in the heating circuit. This is done for technical reasons:

- Polypropylene has high mechanical strength when heated within 120-160℃. Even under slight internal pressure, the polypropylene pipe swells and "flows". Reinforced with glass fiber is able to withstand 100 ℃ for several thousand hours (GOST R 52134-2003).

- The coefficient of thermal expansion for a conventional polypropylene pipe is 0.15 mm / m * K, for a glass fiber reinforced pipe - 0.03 mm / m * K. The risk of breakage of solder joints during heating is several times lower.

You can find a lot of statements that fiberglass reinforced pipes are better protected from oxygen and ultraviolet radiation. But this is a publicity stunt. If it is required to lay a section of a pipeline for hot water supply or heating on the street, then only a protective cover made of polyethylene foam can save a polypropylene pipe.

It must be done in any case in order not to lose heat and at the same time protect the surface from destructive secondary polymerization. If left as is, polypropylene will be covered with the smallest network of microcracks, and after another couple of years, the line will begin to sweat with water, regardless of whether the pipe is reinforced or not.

Why fiberglass reinforced blanks outperform aluminum foil blanks

The technology for the production of pipes reinforced with fiberglass is somewhat simpler than in the version with aluminum foil reinforcement, although the cost of the finished product is somewhat more expensive. The main thing is that the stages of gluing aluminum with a polypropylene tubular blank and subsequent welding of the metal edges are excluded. The greatest number of marriage occurs at this stage.

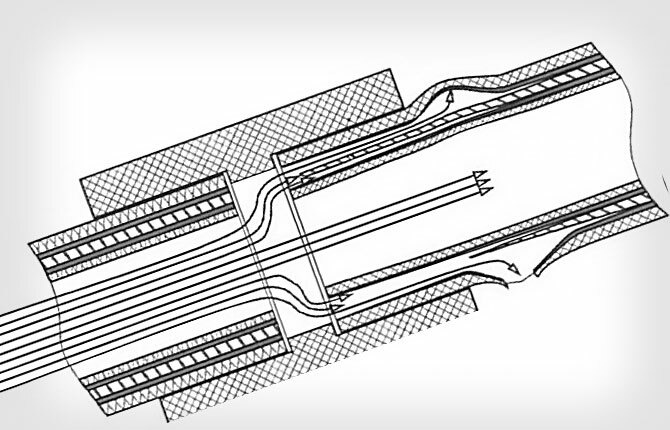

In the case of fiberglass reinforcement, the melt is simply subjected to an initial extrusion through a screw press. After a little cooling to form a tubular shape, to the outer surface of the hot method, a layer of a mixture of polypropylene and glass fibers is glued, the content of which reaches up to 30%. The last layer is made by hot surfacing of a protective mass of PPR-polypropylene.

It turns out that the volume of manufacturing costs is higher, but the quality of the pipe reinforced with fiberglass is higher.

What is characteristic of a polypropylene pipe reinforced with fiberglass

If we compare pipes made of polypropylene with reinforced aluminum and fiberglass, then, at first glance, there are not so many differences. They have almost the same performance characteristics. The most popular PN25 pipe with an aluminum foil underlayer operates at the same temperatures and pressures as a fiberglass reinforced one. The thermal expansion coefficient is 0.035 mm/m*K and 0.031 mm/m*K. The service life is about the same.

But there are differences that must be taken into account when designing and operating heating systems. A tubular billet reinforced with aluminum foil is noticeably less resistant to thermal shocks and overheating. For example, when water boils or superheated steam is released into the heating circuit. The coefficient of thermal expansion of aluminum is 0.022 mm/m*K, for the PPR polypropylene matrix it is 0.15 mm/m*K. The difference is almost sevenfold. Therefore, the metal can flake off the base.

Workpieces reinforced with fiberglass do not have this problem. Glass fibers chopped from fiber are microfibers 500 microns long and 13 microns in diameter. Material - inert quartz glass. No delamination under thermal shock or mechanical stress occurs.

What kind of heating do you have?

Central.

0%

Gas boiler.

0%

Electrical.

0%

Solid fuel boiler.

0%

Furnace.

0%

Your choice in the comments.

0%

Voted: 0

Safety

The fact of using fiberglass in the production of polypropylene pipes may raise doubts or concerns. Manufacturers declare products as safe, suitable for use in both heating circuits and drinking water pipes.

It really is. Pipes reinforced with glass fiber have a strong and thick, 1.2-3 mm, inner layer that protects the water flow from contact with glass fiber.

Many manufacturers cite the results of pumping a sand-water mixture through a standard polypropylene blank with a fiberglass underlayer as confirmation. For a thousand hours, the abrasive wear of the inner surface of the wall amounted to several percent. If you recalculate for the service life, then the complete abrasion of the inner polypropylene layer until the opening of the glass-reinforced layer will occur in 50 years of operation.

Soldering Reliability

The use of polypropylene pipe blanks with fiberglass is interesting in that the risk of internal corrosion of the metal is removed, as is the case with an aluminum sublayer. Before soldering, aluminum must be cut to ensure a reliable solder connection of the inner layer with the material of the coupling or fitting. The edge remains outside of the weld and can interact with water. As a result, the metal corrodes to a gray alumina powder.

Soldering a coupling with a pipe reinforced with fiberglass is carried out in the same way as for conventional polypropylene blanks. If you follow the technology, then the fiber layer is tightly sealed in the thickness of the polypropylene fitting.

How to choose for heating

The first thing you need to pay attention to is the availability of a certificate and a technical passport for finished products. It is from these two documents that you need to obtain information about the structure and characteristics of polypropylene pipes.

Two parameters are important:

- the percentage of glass fiber in the reinforcing layer;

- thickness of the middle layer.

Typically, the content of glass fibers in a polypropylene matrix varies from 15% to 30% for different manufacturers. 20-25% is considered optimal.

It is believed that the higher the level of reinforcement, the lower the coefficient of thermal expansion, the stiffer and stronger the walls of the polypropylene pipe. The better the material tolerates heat and worse - cooling below the freezing point of water. If the usual polypropylene line, due to its high plasticity, retains its characteristics after the freeze / thaw cycle, then the fiberglass reinforced line may crack.

The thickness of the reinforcing layer should be at least 1/3 of the wall thickness. This parameter is easy to control by the cross section of the workpiece, the reinforcing layer is always painted in red, green or blue.

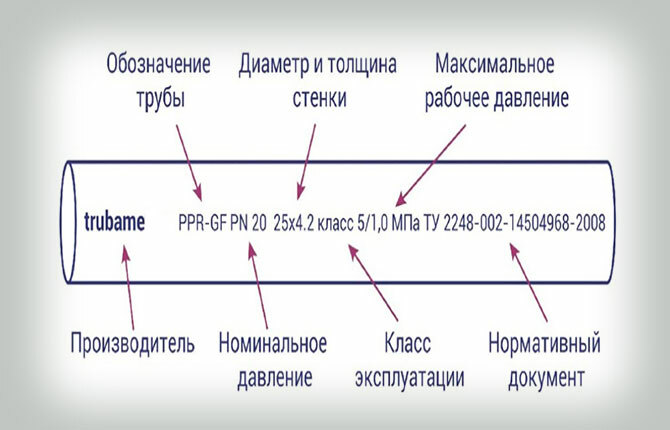

Marking

Information about the brand is applied to the outer surface by thermal printing along the axis of the pipe billet. First of all, we look for the word Fiber in the name. The most common variant is "PPR Fiber PN25", meaning glass fiber reinforced pipe.

Often the marking is performed in the form of a sequence of letters of the Latin alphabet. The letter code can be as simple as PPR/PPR-FB/PPR - fiber reinforced polypropylene pipe. Or complex - PP-RCT / PP-RCT-GFHKF / PP-RCT. In this case, the outer and inner layers are made of heat-stabilized polypropylene, the inner layer already with the addition of glass fiber (GF) with fibers of a certain shape.

The label must include the date of manufacture. The shelf life of polypropylene pipes is 2 years.

In addition to information about the polypropylene matrix and reinforcement material, the marking includes information about the diameter, wall thickness and maximum pressure.

Manufacturers and color

The first thing they pay attention to is the color of the pipe blanks. In fact, it is not of decisive importance - this is one of the ways to protect against forgery.

The best in quality are Italian reinforced pipes Valtek white. When choosing, you need to pay attention to the cut of the workpiece. There should not be any sparkles or glass shine. Before use, fiberglass undergoes a special treatment - matting to remove gloss and increase the surface roughness.

Czech pipes of the FV Plast company of the FAZER brand are also considered to be of high quality. Blanks are white or gray with a green longitudinal stripe and a layer of reinforcement.

Of the Turkish brands, the Kalde brand is distinguished by high quality. If you are looking for real quality, then Banninger's green pipes of the Watertec and Climatec brands may be the best solution.

Of the Russian manufacturers, polypropylene pipes of the Metak company can be noted. Fiberglass-reinforced pipe blanks PN25, white, are produced under the common brand "METAK FIBER". Reviews vary, but mostly positive.

Reinforced pipes with fiberglass from the Tekhstroy company are popular. The brand's products are actively advertised as certified according to European standards. Its advantage is an affordable price and a relatively small number of negative reviews.

In addition to green, gray and classic white pipes, black polypropylene products can be found on the market. Manufacturing companies explain the unusual choice by the desire to protect polypropylene from ultraviolet exposure by adding up to 2% carbon black to the melt.

It is believed that the black surface absorbs up to 98% of sunlight. But only ultraviolet is dangerous for polypropylene mass, and it is best absorbed by translucent green plastics. Well it reflects the surface of a white color with gloss. Therefore, any speculation on the topic of coloring should be treated critically.

Mounting Features

The technology for soldering pipe blanks reinforced with fiberglass is practically the same as the technique used for conventional polypropylene pipes. Since the base of the reinforced part is 70% polypropylene, there is no need to cut off the top layer, as is done when soldering pipes with aluminum foil. The workpiece and fitting are heated on the nozzles of an electric soldering iron, after which they are connected with a slight compressive force.

The only thing to pay attention to:

- Cutting blanks is performed with gloves and specialized scissors or a cutter. The less sawdust and scraps, the lower the risk of glass fiber getting on the skin of the hands.

- For soldering water pipes, you need to purchase fittings and reinforced pipes from the same manufacturer, preferably even one batch.

Such giants as "Valtek" or "Banninger”, product quality is consistently high, the composition of the fiberglass-reinforced layer practically does not change due to large volumes of production. For small manufacturers, the coefficient of thermal expansion can "float" from batch to batch. The best seam quality is obtained when welding polypropylene parts with the same characteristics.

Pipes reinforced with fiberglass may in the future replace polypropylene with aluminum foil. The polypropylene matrix fused with glass fiber proved to be more convenient to use, resistant to hot water and thermal shock.

Welding of polypropylene pipes reinforced with fiberglass: video.

Share your own experience with glass-filled polypropylene in the comments. How much does the presence of a reinforcing layer affect soldering and operation? Bookmark this article so you can easily find it.