Almost all flights of stairs installed in private houses, in order to ensure traffic safety, need to install handrails or railings, especially if children live in the house. Of course, it’s easier to hire a craftsman who will quickly make a railing for the stairs, but it’s much more pleasant to do it yourself. How to do and what to consider when assembling with your own hands?

There are several methods for making stair railings. For this, the purchase of finished parts or self-production can be chosen.

The content of the article:

-

Which railing to choose

- Homemade or ready made

- metal or wooden

- Choice of wood

- Design choice

-

How to make the necessary parts

- support poles

- handrails

- filling

-

How to mount a railing

- Pole installation

- Installation of balusters

- Handrail Installation

Which railing to choose

Initially, it is important to consider the material of the stairs itself. If it is wood, then a similar material or metal would be a good option. The choice can be influenced by the design of the room. If it is made in high-tech or techno style, then it is unlikely that a staircase with wooden railings will fit into the overall design.

Attention! Only by choosing the type of railing, you can decide whether they will be made independently or all actions will be performed by the master.

Homemade or ready made

Someone will say that it is easier to buy ready-made parts and assemble them on the spot. It is impossible to disagree with this. However, independent production of themes captivates that for this you need to apply your imagination and strength. Pros and cons of homemade and ready-made railings:

-

Handrail for stairs with your own hands. By choosing this option, you can save on hiring and paying for the services of a master. You can start self-assembly only if you are completely confident in your own abilities. Keep in mind that you will probably need turning equipment to work. That is, a good ladder cannot be assembled with an ax and a hacksaw. Also here you will need good knowledge in geometry and drawing to take measurements and correctly fix them on the finished drawing.

Assembling a railing for a staircase requires a lot of care and patience.

Attention! You should not tempt fate and try to assemble a railing for a staircase without drawing up a good drawing. Small miscalculations can play a cruel joke, and when everything is almost over, an error in the calculations will definitely make itself felt. No wonder they say: "Measure seven times, cut once." - Prefabricated railings for stairs. This option is practical and reduces the risk of miscalculations to a minimum. When buying a design, you take parts with the ability to adjust to the assembly conditions. For example, movable brackets are attached to metal balusters, allowing you to fix the handrails for stairs at any angle of inclination.

Attention! Ready-made railings for the stairs exclude the possibility of self-selection of the design of the structure. Of course, with money in your pocket, you can make a railing to order, but this is an additional waste of money.

metal or wooden

The choice of material is primarily influenced not so much by the preferences of the owner of the house as by the skill of a specialist in this profile of work:

-

Metal railings. There are several options for assembling metal railings for stairs - this is forging, welding and installing finished stainless steel models. All ready-made options with a sufficient level of skill look beautiful and elegant. The strength of such a structure is rated as high. However, to assemble a railing for a metal staircase, even if it is assembled from simple materials, a lot of experience is required.

The combination of forged details and wooden elements for the stair railing fits well into the interior of a classic and country style.

- Wooden railing for stairs. Models adapted for placement in country or Provence style interiors. If the master has sufficient experience on woodworking machines, carved decorative balusters and semicircular railings will decorate the room in a classic style. In cases where the railing for the stairs is assembled without decorative processing, even an inexperienced worker can cope with the task. If there is no carpentry experience, then you can order finished parts.

Next, a master class and advice from the masters on the selection of parts and installation of wooden railings for the stairs will be considered.

This is interesting! How to make a staircase to the second floor with your own hands: step-by-step instructions for manufacturing and installation. How to make a spiral staircase with your own hands.

Choice of wood

Having chosen wood as the main material, it remains to choose a grade. Everyone has their own differences. Some are expressive with an accentuated texture, others are less noticeable, but with excellent strength indicators.

Recommendation! For flights of stairs placed inside the house or on the porch, it is important to pay attention to the strength of the material. After all, it is she who determines the durability of the manufactured structure.

Tree species suitable for the manufacture of railings:

-

If the goal is to install a railing on the stairs in the utility room, then varieties of inexpensive trees are suitable here: pine, spruce, birch or aspen. But at the same time, it is necessary to take into account the humidity of the room - high rates negatively affect the safety of the finished model. Masters may advise processing, but these are additional costs.

The quality of the lumber determines the reliability and durability of the finished stair railing. It is important to consider storage conditions.

- It will be possible to save on the processing of finished parts if coniferous trees, alder or aspen are used for the manufacture of railings.

- Such types of wood as oak, beech, larch and pine have good resistance to decay.

- If money is not an issue, then opt for varieties such as oak, beech, ash or walnut. They have excellent strength properties. Stairs from them are designed for a long service life, and the texture will delight the owner with its attractiveness.

Before purchasing stair railing material, evaluate its moisture content. You can do this with a special device or take the word of the seller. Visual assessment of weight and tactile contact will also give a result, but errors are possible with this method of assessment.

The moisture content of wood should not exceed 12-16%. Otherwise, during natural drying, the tree may lead, it may crack or deform. Therefore, if a purchase is made without checking with special equipment, then it will have to be kept in a dry and ventilated place until it is suitable.

Recommendation! If you do not have enough experience in combining different types of wood, then use the same species for the manufacture of stairs and railings.

Design choice

The definition of the form of the future structure is formed at the level of mental perception. Come up with an image, then sketch it schematically on a piece of paper. If you like, then you can proceed to the construction of a drawing of the stairs.

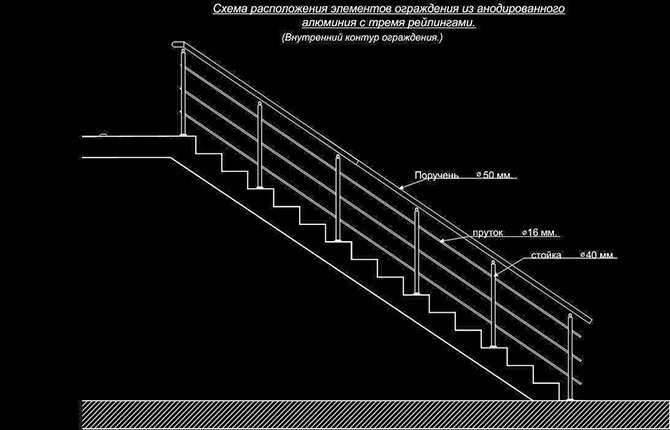

Something like this might look like a drawing of a railing for a staircase.

Next, the stability and strength of the invented model are analyzed. Remember that the main load falls on the supporting pillars. Consequently, they should look more massive, and for their manufacture, varieties of trees of the most durable species are involved.

The support post is usually installed at the beginning and end of the flight of stairs. In order to avoid sagging of handrails in large spans, it is recommended to mount one or more additional supporting elements. The appearance will not be spoiled by this. The standard distance between posts cannot exceed 150 cm.

Stability is also affected by the chosen shape for the balusters. If these are thin slats, then in this model they relied on appearance, without thinking about reliability. It will be useful to install support poles a little more often - every linear meter. For massive balusters, the span can be extended up to 170-180 cm, depending on the reliability of the manufactured elements.

There are the following types of filling:

- solid - the entire square is filled with plywood, glass or other sheet material;

- cruciform - the design is close to the Scandinavian style, bars are stuffed diagonally:

- rectilinear - involves vertical or horizontal filling with bars, slats;

- combined is a combination of several types in one model.

When installing a railing for a staircase, in order to get a reliable and aesthetically pleasing structure, the masters recommend remembering a few rules. They concern the sizes:

- railing height (about 90 cm) - the distance from the plane of the step to the upper point of the handrail is taken for calculation;

- the size of the section of the support column is not less than 10x10 cm;

- the section of the balusters is determined from the span and the frequency of the installed elements - 4-8.5 cm;

- the diameter of the handrail should be comfortable for the palm of a person of average build to grasp - within 60 mm;

- the distance between rectilinearly arranged bars is no more than 20 cm.

Attention! If there are small children in the house who independently move up the steps, it is better to be safe and choose the minimum dimensions for the distance between the vertical balusters. As a rule, they do not exceed 12-15 cm. But it is better to refuse horizontally located jumpers, since a child can easily climb up and climb over the fence along them.

How to make the necessary parts

The choice of method for manufacturing parts is determined by the presence of specialized equipment in the home workshop. Naturally, if there is one, the owner will want to make the railing for the stairs a more complex and attractive configuration. However, in most cases, this is a standard carpenter's set: a hacksaw, an ax, a drill and other hand tools.

Special equipment helps to get beautiful and geometrically correctly folded railings for stairs.

support poles

For pillars, two versions are possible - these are hollow and made of solid wood. The first type is a prefabricated support column in the form of a hollow box. Plywood sheets or narrow boards can be used for manufacturing. For decor, glazing beads, slats of a separate fastening are selected.

The second type of solid wood is more understandable for manufacturing. A solid beam is taken, and a finished part is made from it. Decoration in this case is done immediately, without stuffing individual elements. This option is more reliable, but has two significant disadvantages - this is a high price and an increase in the load on the flight of stairs due to the large mass of the part.

Recommendation! In places of contact and fixation of the handrail with the support post, it is recommended to produce a face of a strict geometric shape. It is much more difficult to mount a figuratively joined face than a square or rectangular one.

handrails

Masters offer for consideration many options for the shape of handrails. This is a semicircle, figured shape with a longitudinal cutout for the fingers, a strict square section and other models. You can choose one or another method for forming a handrail based on your experience. How professionally savvy are you to make your own curly stair railing piece?

Of course, it is difficult to repeat a brilliant idea if you do not have the necessary turning equipment at hand. You can sit and grind all the elements with your hands, but for a very long time. I would like to note that the shape of the product can be anything, but one requirement must be met: the hand must slide along the top of the handrail without feeling any obstacles and discomfort.

The hand along the path of movement should not meet any obstacles, only in this way the operation of the railing for the stairs can be called comfortable.

Recommendation! To get a semi-circular workpiece and spend a minimum of time, make parts in the shape of a hexagon, cutting off excess parts. The resulting workpiece is ground to form a semicircle.

filling

The most difficult stage in the assembly of the railing for the stairs to the second floor is the manufacture and adjustment of the filling. If we consider simple manufacturing methods as an option, then figured flat dies cut with a jigsaw and straight crossbars can be attributed to this category. They do not require complex fitting, and for their manufacture you need a minimum of tools.

If there is a desire to make balusters in a classic style, but there is no special turning equipment, then round or square blanks can be made from timber. And to give relief, go through a manual milling machine.

To fasten figured boards, fasten one guide at the top and bottom and fix the parts on top. In order not to distinguish between the front and back sides, it is recommended to mount flat balusters on both sides of the rails. Thus, a three-dimensional structure can be obtained.

Recommendation! Considering that the angle of inclination is adjusted in place, the baluster blanks are made a little longer.

How to mount a railing

Before starting the installation, the installation sites and fastening of future parts are marked. It is more convenient to do this with a marker or chalk, which at the end of the work can be wiped off with a damp cloth. Regardless of the choice of type of filling, the installation of railings always begins with the installation of support pillars.

Pole installation

This is a very important stage, the accuracy of which will depend on the reliability and aesthetics of the stair railing. To start work, you need to understand where the first support column will be installed: on the step or near it. As a rule, this does not affect the installation of the next support, unless, of course, the length of the flight of stairs allows you to expand the boundaries of the balustrade.

The span of the stair railing balustrade must be determined in advance. Small miscalculations can cause the top rail to deform under its own load.

Attention! If the design of the stairs to the second floor involves an intermediate platform, then a turn is provided in this place and two support pillars are needed here. One will be the end of the lower balustrade, and the second will be the beginning for the next. In cases where the structure does not imply a rotary continuation, then the final support column will be installed in a single copy.

How to fix the pole depends on the type of its construction. For hollow models, there is an effective way using the boss:

- take internal measurements from the support post;

- according to the data obtained, cut the boss out of a bar or hemp;

- fix the received part with the help of wooden dowels to the floor;

- to fix the post, the edges of the boss are coated with wood glue and landing on the workpiece.

Recommendation!For reliable fixation, the lower part of the column is coated with silicone sealant.

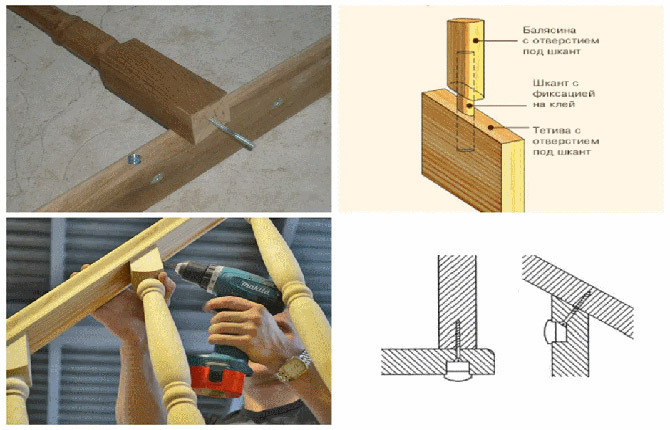

Solid wood support poles are fixed with dowels, hairpins or furniture ties. All cases require the use of wood glue.

Installation of balusters

First, the installation sites of the balusters are marked according to the example of the supporting pillars. Only in this case, so that the alignment of the elements is not disturbed, it is necessary to apply a guide rail when marking the central center line. How to do it:

- put marks on the lower and upper steps;

- lay the guide rail, aligning both marks;

- put risks in the places of the proposed installation of other balusters or draw a solid center line along the entire span.

One way to fix balusters in stair railings. It has some difficulties, but from that it is more reliable.

Recommendation! It is convenient to use a template to determine the transverse centerline. Make a blank that will define a clear distance from the edge of the step to the center of the baluster. Applying it to the edge of the step, put marks in all places where the balusters will stand.

To move on to the next step, fastening parts, you need to determine the method: to the step, to the top or side of the bowstring (guide). Let's take a look at the first option:

- Drill dowel holes in the center of the crosshairs. To improve the stability of the parts, it is recommended to use a dowel with a large diameter, for example 15-20 mm.

- Secure the fasteners with wood glue. It is better to give time for the glue to harden. Half an hour is enough.

- Apply adhesive solution to the dowel caps and install the balusters.

- Temporarily install a handrail. This will make it easier to align the balustrade with respect to the center centerline.

- Waiting for the glue to dry. Proceed to the next step.

- The holes in the balusters must be pre-drilled. Following the example with the lower part, we mount the dowels.

The final stage is the installation of handrails and fastening to the supporting pillars.

Handrail Installation

The complexity of installing handrails is that they need to be adjusted in relation to the balusters and supporting pillars. The easiest way to cope with this task is to fix the handrail in the support post using self-tapping screws.

But not always the structure allows this to be done without losing the overall attractiveness, so the best option would be to make the sole. However, it requires precise accuracy, which not every master can do.

Pre-fixing the balusters helps to maintain the correct geometry of the railing for the stairs.

When it comes to attaching handrails to balusters, there is no better way than using a banister. It is so simple that even an untrained youth can cope with the task. To do this, you need to fix the railing bar to the balusters with self-tapping screws.

After that, install a handrail on it. For convenience, it has a groove along the entire length of the handrail. Fix with self-tapping screws.

Unfortunately, the manufacture and installation of railings for stairs to the second floor or porch require experience, without which it is better not to proceed with the implementation of the plan. You can always purchase ready-made models and, having adjusted them in size, install them in your home.

However, one does not always want to solve problems at the expense of someone else's mind. It is for people who, even without sufficient experience, will try and eventually do what they intended, and this material was written.