The first number in the repair shop has always been and remains lathes. Despite the dominance of combined models with CNC and milling nozzles, most amateurs - do-it-yourselfers and even craftsmen - prefers to use conventional screw-cutting lathes built according to the classical scheme, sometimes made back in the days THE USSR.

The content of the article:

-

What to look for when choosing?

- The most important parameters of a lathe

-

Overview of the best lathes

- Desktop machine PROMA SM-300E

- Machine Triod LAMP-500P/400

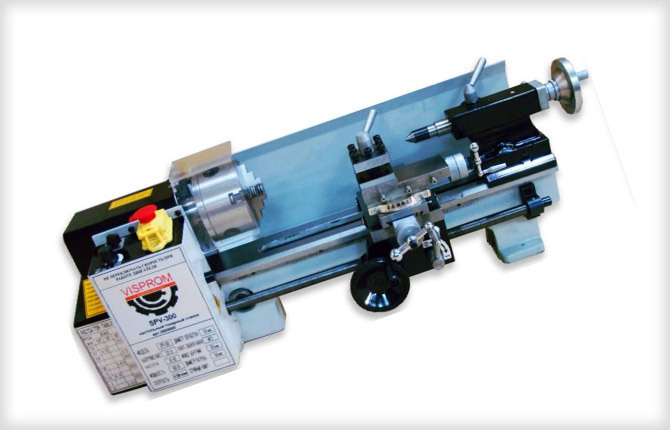

- VISPROM SPV-300

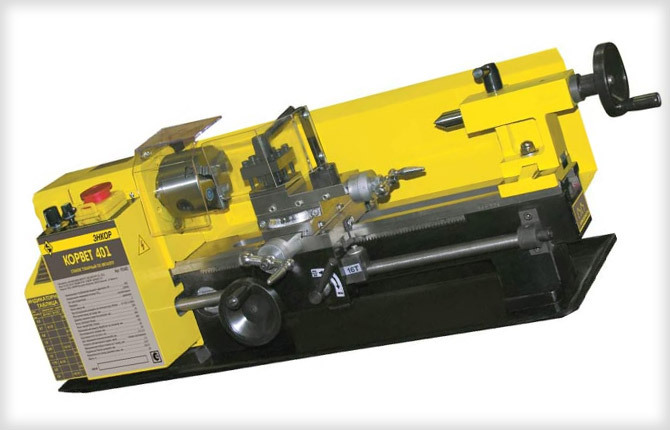

- ENCOR CORVETTE 401

- Ferrox ML 110x125 VS

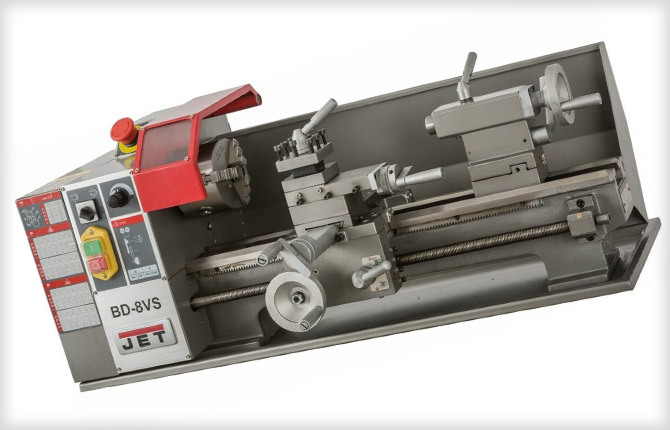

- H3 JET BD-8VS

- STALEX SBL-250/550

- MetalMaster MML 1830V

What to look for when choosing?

It cannot be said that the old Soviet turning equipment was bad. Most of the machine park of that era are monsters like the 16K20 model. Huge, heavy, with powerful electric motors designed to be connected to a three-phase power supply network. At one time, these were the best lathes. It was not difficult to work on such machines, their accuracy was small, but quite sufficient for the purposes of mechanical engineering.

There were also small lathes of the TV320 type. They are more suitable for a home workshop, but their accuracy is low, so they are not suitable for more than amateur homemade products. The most accurate are desktop-type watch machines. But these are specialized lathes for non-ferrous metal, and as a rule, they are not used for amateur work.

Russian, American, German, Czech models are massively copied by Chinese companies. Therefore, if desired, you can find both the old original and the new replica in the form of a Chinese lathe. If you need a good wood lathe, you can buy equipment made in the Baltic countries or Belarus.

The most important characteristics of the lathe:

- vernier feed accuracy in the longitudinal and transverse direction of the caliper;

- bed and gearbox material;

- engine power;

- the method of switching the revolutions of rotation of the cartridge - belt, chain or gear;

- rotation speed, number of switching steps;

- chuck device for fastening the workpiece;

- material and design of the frame.

It is clear that when choosing a lathe for a garage or a small home workshop, they first of all pay attention to the dimensions, weight, and the required number of phases for connecting to the mains. Therefore, for home creativity, light desktop models with a welded frame body and 220 V power supply are usually purchased.

Three-jaw chuck for fastening the workpiece, with a maximum jaw opening of up to 90 mm. Rotation speed control electronic or by means of a pulley system. Such equipment provides turning accuracy up to 0.1 mm.

For repair work in a car repair shop, floor-standing units with a cast-iron frame, 380 V power supply and a four-jaw chuck are used. Such models already have the functions of an automatic caliper feeder from cutters in the longitudinal and transverse directions. The rotation speed is selected by switching pairs of gears on a manual gearbox. The price for semi-professional lathes is about an order of magnitude higher than for amateur-class models.

The most important parameters of a lathe

If the equipment for small turning works with low accuracy, then you can choose any desktop machine with an engine with a power of 800-1000 W and a speed of 250-2100 rpm. Chuck diameter - up to 50 mm, transverse and longitudinal feed 80-120 mm. This is enough for making small crafts.

To obtain increased machining accuracy, the design of the machine must meet the minimum requirements for turning equipment:

- The bed must be rigid and massive, mounted on a concrete floor, in order to effectively dampen the vibrations that occur during the turning process.

- The jaw chuck in which the workpiece is clamped must be mounted on a separate shaft, on at least two bearings. The transmission of torque from the electric motor can be transmitted by a belt or gear drive. The cartridge on the motor shaft is installed only in the cheapest Chinese models.

- The system for mounting the cutter on the movable part of the lathe (caliper) should provide the ability to accurately control the position of the tool in height and angle to the longitudinal axis.

- To move the caliper, screws with trapezoidal thrust threads must be used. Rotation can be from handwheels or an additional electric motor.

On high-quality turning equipment, flywheels have verniers with graduations up to tenths and hundredths of a millimeter. By making one turn with the handwheel, you can see how far the cutting edge of the cutter has traveled in hundredths (tenths) of a millimeter.

This will come in handy! Overview of the best grinders: characteristics, advantages, disadvantages, price.

Overview of the best lathes

The choice of equipment must begin with the frame. If all other elements can still be somehow adjusted or improved, then on a weak bed, no, even the best lathe will not provide the required accuracy.

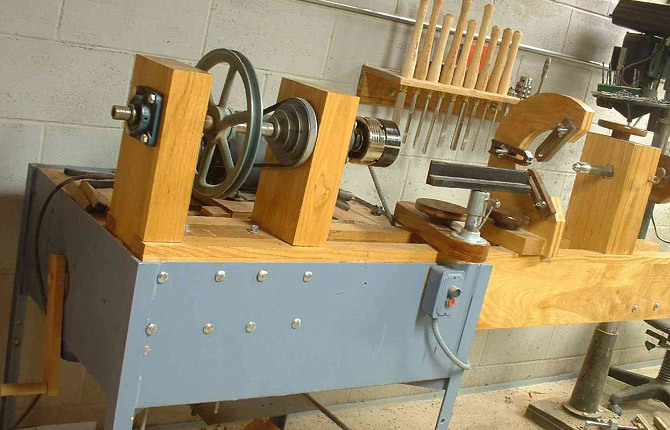

As an example, consider the Corvette 70 wood lathe. Cast iron bed with ground headstock. The motor transmits torque to a plan-washer mounted on a separate shaft. In general, the design is successful and can be used for simple woodturning.

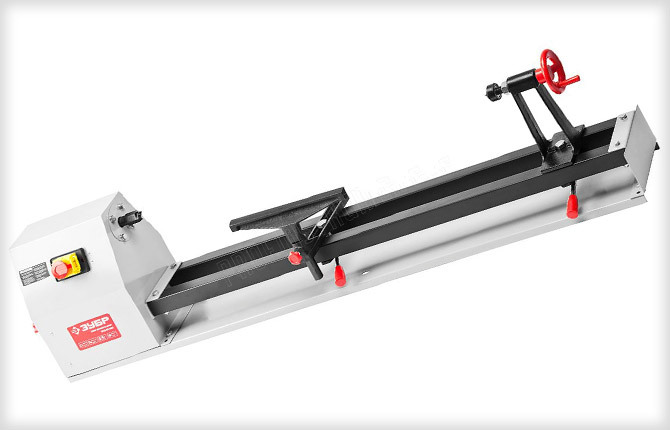

The second option is a wood lathe ZUBR 3STD-350. Made from sheet metal.

Drive shaft directly from the electric motor. The quality is low, at best you can make handles for shovels.

Advice! A good lathe is a very complex machine with a large number of parts and assemblies. The quality of equipment largely depends on the technology and culture of production. Therefore, it is advisable to choose lathes from manufacturing companies known for the high quality of precision mechanics.

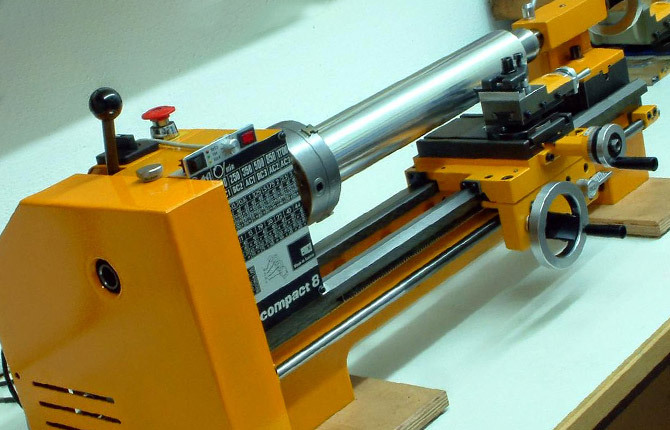

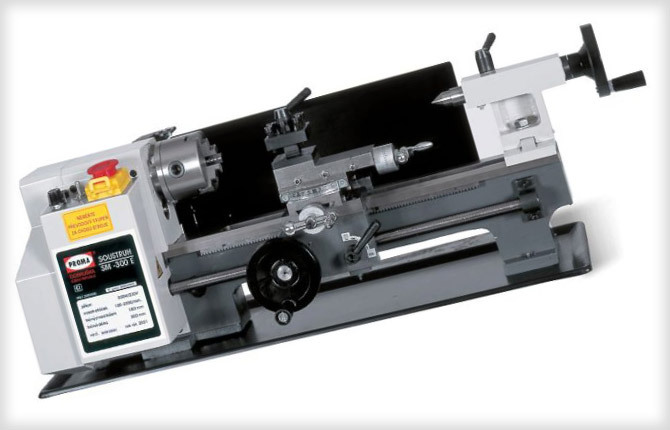

Desktop machine PROMA SM-300E

Produced in China and the Czech Republic. Today in the review is one of the best small desktop machines. Equipment for turning - turning and boring of cylindrical surfaces, threading, drilling, facing and grooving. Functionally, it's pretty simple. This is the level of a home apparatus for small parts.

Characteristics:

- collector type motor 300 W. It is possible to smoothly and stepwise adjust the spindle speed from 100 to 2500 rpm;

- the electric motor is located in the lower part of a very rigid steel frame, the transmission of torque is carried out using pulleys and a belt;

- three-jaw chuck, self-centering, maximum diameter of the cylindrical surface being machined 120 mm;

- caliper feed in the transverse direction - 65 mm, in the longitudinal direction - 300 mm;

- distance between centers - 250 mm;

- power supply - 220V;

- weight - 40 kg.

The design turned out to be quite low-power, but its capabilities are sufficient for processing parts with a diameter of up to 40 mm. The main thing is the processing accuracy of 0.01 mm for Czech models and 0.1 for Chinese ones. If possible, then you need to choose PROMA SM-300E analogues made in the Czech Republic. They are in high demand due to the very high quality assembly and fitting of mechanical parts. There are no backlashes, so the accuracy is much higher than that of competitors.

Price - 110 thousand rubles. rub. Warranty - 12 months.

Machine Triod LAMP-500P/400

Universal turning equipment of a well-known Russian brand. But the machine is produced in China. This model can be installed in a garage or a small repair shop. Despite the fact that the equipment belongs to the desktop amateur class, it has a very heavy and massive cast iron frame. Weight - 130 kg, so a locksmith workbench is required for work. Suitable for a garage.

The design uses a conventional asynchronous motor with a power of 500 watts. The transmission of torque from the motor to the spindle shaft is done by a 6-speed manual gearbox, from 170 rpm to 1950 rpm. Rotary knobs are used for adjustment and adjustment. To cut threads, you have to change the gears manually. This is the traditional practice of adjusting for knurling or cutting inch and pipe threads.

In a three-jaw chuck, parts with a diameter of up to 100 mm can be fastened. The distance between centers is 550 mm. Caliper travel - 500 mm and 130 mm. Processing accuracy - 0.04 mm.

Triod LAMP-500P/400 can perform almost all turning operations. The machine turned out at the level of semi-industrial equipment. Based on the technical solutions laid down in the design, the Triod looks more perfect, but the build quality varies greatly even within the same batch of equipment.

Price - 150-160 thousand rubles. rub., warranty - 12 months.

VISPROM SPV-300

One of the simplest desktop lathes. VISPROM brand equipment is developed in Russia and manufactured in China. The lathe is positioned as equipment for amateur aircraft and ship modeling. At the same time, the price is quite high for such equipment - 90-91 thousand rubles. rub. The main purpose is turning parts made of bronze, brass, aluminum alloys.

Characteristics:

- motor power - 550 W, the machine is equipped with an asynchronous motor with continuously variable shaft speed;

- torque transmission - gear;

- longitudinal travel of the caliper - 65 mm, transverse - 35 mm;

- three-jaw chuck - 100 mm.

The peculiarity is the high quality of all nodes, careful fit without backlash. Turning equipment is durable, but when machining parts made of structural steels, the accuracy and surface quality are reduced by an order of magnitude.

Warranty period — 12 months.

ENCOR CORVETTE 401

Russian brand, the machine itself is made in China. This is a desktop type of equipment for the simplest turning operations, such as turning, boring holes, cutting cylindrical grooves, threading. Suitable for home.

According to the concept and technical capabilities, the KORVET 401 was supposed to become a competitor for the Czech-Chinese PROMA SM-300E. These are lathes of approximately the same class, but differ in quality and price. CORVETTE is at least two times cheaper, the quality is appropriate.

Characteristics:

- weight - 36 kg, can be installed on a workbench or on a special stand table;

- the speed is set by smoothly adjusting the speed of the collector motor of 400 W within the range of 0-1100 rpm or 1100-2500 rpm;

- operating voltage - 220 V;

- the rotational moment from the motor to the shaft with the cartridge is transmitted by a system of belts and pulleys;

- for threading, a pair of “gear-gear” is installed on the caliper drive. You can cut any profile in increments of 0.5-2.5 mm.

The three-jaw chuck accepts workpieces up to 50 mm in diameter. Caliper travel - 35 mm and 65 mm. If turning the workpiece in the centers, then its length should not be more than 300 mm. In general, the lathe is a good impression, but the new KORVET 401 requires a little additional setup before it can turn parts to an accuracy of 0.1 mm. The price of a lathe is 62,000 rubles, the warranty is 36 months from the date of sale.

Ferrox ML 110x125 VS

Desktop model of a lathe for processing small parts from any steels and alloys, except for titanium and manganese stainless steel. It is used mainly for minor repairs of household appliances. In addition to turning, you can perform round grinding operations.

Characteristics:

- weight - 13 kg, the machine can be stored in the garage or even in the pantry of the apartment;

- collector motor 250 W, speed control smooth, from 400 to 3600 rpm;

- caliper travel in the transverse direction 45 mm, in the longitudinal direction - 125 mm;

- lathe chuck by 50 mm, so the maximum diameter of the workpiece is limited to 30 mm.

Ferrox ML 110x125 VS is mainly used for turning in centers, so the accuracy of turning, depending on the feed, is 0.05-0.1 mm.

Price - 49 thousand rubles. rub., warranty - 1 year from the date of registration of the purchase.

H3 JET BD-8VS

Popular model of the famous Swiss brand "JET". Information about it is in any review of the top best lathes. If the previous models of machine equipment were designed and built according to traditional Soviet schemes, then the JET BD-8VS lathe is made according to European standards. This means that, in addition to high technical characteristics and quality, the scheme includes technical solutions that ensure the safety of the employee.

Characteristics:

- collector motor with a power of 600 W or 1000 W. Rotation speed - 50-2500 rpm, can be adjusted smoothly using an electronic board. The instantaneous value is displayed on a digital indicator;

- Welded bed with a cast iron central beam, the supporting surface of which is ground to class III. Lathe weight - 58 kg;

- caliper transverse travel - 75 mm, longitudinal - 100 mm;

- center-to-center distance - 400 mm;

- torque transmission is carried out using gears. There is a possibility of reversal.

The machine can perform all types of turning operations, including thread rolling. In addition, in the three-jaw chuck, the engine start system has a special security system (contact and reed switch). It blocks the engine while the workpiece key is in the chuck. In a conventional machine, switching on with the key inserted, if the turner forgot to remove it from the socket in the chuck, leads to serious injuries.

In terms of comfort during operation, the JET BD-8VS lathe clearly surpasses most Chinese and Russian models.

The accuracy of the machine is 0.01 mm in the transverse direction and 0.1 mm in the longitudinal direction. The build quality is high, there are backlashes, but not of critical importance. The price of a lathe is 130 thousand rubles. rub., warranty - 1 year.

STALEX SBL-250/550

One of the most powerful lathes considered in the ranking of the best. The model was developed in the Russian Federation, is assembled in China partially using Russian parts and assemblies.

The lathe is assembled on a full-fledged cast-iron bed, so the weight is more than 120 kg. The equipment can be installed on a workbench, but it is best to make a reinforced concrete podium. The operation of the 1100 W asynchronous motor creates perceptible vibrations. Therefore, if it is planned to perform fairly accurate finishing operations on a lathe, then a concrete floor cannot be dispensed with.

Characteristics:

- three-jaw chuck speed - 50-2000 rpm, six turning modes;

- caliper travel - 70 mm in the direction transverse to the axis and 120 mm in the longitudinal direction. There is an automatic feed;

- holders with a cross section of up to 12 mm are placed in the tool holder, in addition to the cutter, a die for threading can be fixed. The threaded surface can be rolled, but for this you will have to install timing gears;

- there is a safety group that blocks the engine when the limit switches are triggered.

The machining accuracy of a lathe is low - 0.1 mm, so it is necessary to sharpen mainly in the centers. The slide on the caliper can be unfastened and turned at an angle. This allows you to sharpen cones of any size.

The advantage of STALEX SBL-250/550 is the use of thrust conical bearings on the shafts. That is, the rigidity of the bed and the drive of the lathe allows you to process parts with greater accuracy. But only after manual tuning and proper tuning.

The price of a lathe is 180 thousand rubles. rub., warranty - 12 months from the date of purchase.

MetalMaster MML 1830V

The model of the lathe was developed in the Russian Federation, but the equipment is manufactured in China. MetalMaster MML 1830V is interesting in that at a price of 99 thousand rubles. rubles, the quality of mechanics and the number of functions are noticeably greater than those of competitors.

The machine weighing 60 kg and with an engine power of 600 W can be classified as a desktop machine. This is a semi-professional turning equipment that can be used for the manufacture of repair kits and parts for washing machines, automotive equipment.

The bed is welded with a central cast-iron beam. The drive from the engine to the cartridge is carried out by means of a pulley and a built-in variator. There is an automatic longitudinal feed of the caliper, which significantly increases the accuracy of turning the workpiece. For fastening blanks, a three-jaw self-centering chuck with a maximum diameter of 50 mm is used.

The only drawback of the lathe is a protective telescopic cover, which should protect the threads on the drive shaft from chips and debris. In fact, the device only collects all the dirt and interferes with the movement of the caliper.

In general, the lathe can be considered as the main competitor of the Swiss-Chinese JET, but with a lower machining accuracy, 0.05 mm.

Price - 99 thousand rubles. rub., warranty - 12 months.

A good lathe is of high build quality. There are no backlashes in the mating units, and under load at maximum engine speed, the structure does not vibrate or sag. It is possible to determine the degree of suitability of the equipment for work only after a practical test of its operation.

Have you used lathes? If yes, which ones? Tell us about your experience in the comments. Also save the article to bookmarks and share it on social networks.