There is always a place for outdoor recreation in the summer cottage or near the cottage. And an indispensable attribute of such a holiday are street swings. Do you agree? Of course, you can order their installation from one of the many private companies or purchase a ready-made kit via the Internet and assemble it yourself. However, in both cases, the cost of quality full size models will be quite high.

But it is much more interesting to build a street swing on your own, especially since there is nothing complicated in this. Next, we will tell you how to make a swing with your own hands from metal, what tools and materials you will need for work, and we will also introduce you to popular swing options.

The content of the article:

-

Popular types of metal swing

- Option number 1 - transformers

- Option number 2 - children's swing

- Option number 3 - spherical models

- Option number 4 - hammocks

- Swing installation method

- Materials, tools, drawings

- Instructions for the construction of a swing

- Conclusions and useful video on the topic

Popular types of metal swing

First of all, you need to decide on the material of manufacture. Metal is the best choice due to its many advantages over other materials.

First, it has high strength. Therefore, the metal structure has a minimum number of reinforcing elements, but can withstand significant weight.

Secondly, the metal is durable, it is much more resistant to external factors such as high humidity, physical influences, temperature changes, etc.

Thirdly, care for the metal swing is minimized. If an outdoor wooden swing needs to be painted annually, then by covering the metal with high-quality paint you can not worry about re-protection for 5-7 years.

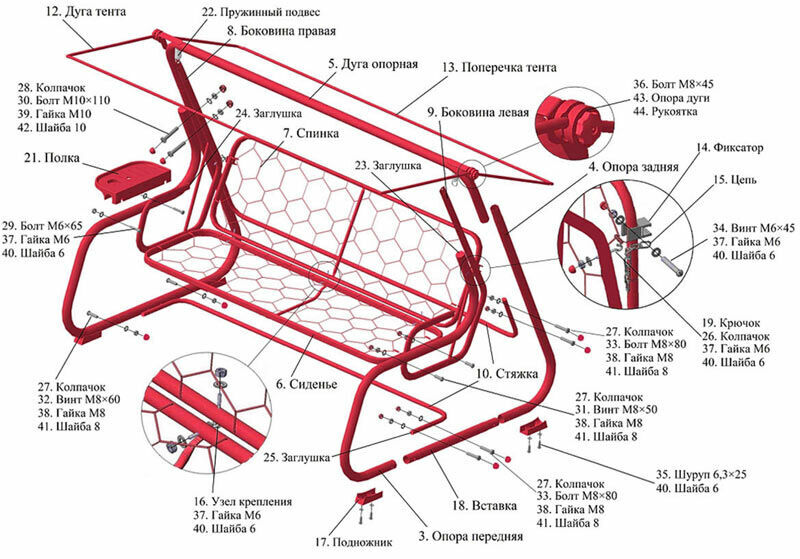

Detailed instructions for one of the prefabricated kits. It can be taken as a basis. However, a large number of parts of complex shape will make the manufacture of such a swing laborious, time-consuming and expensive.

By design, street swings are divided into single and multi-seat. In most cases, the choice is made in favor of the latter, since they can be used not only for sitting several people, but also for lying.

The remaining differences related to the size of the seat, the materials for the manufacture of the roof and seat, the presence of handrails refer to the nuances associated with the comfort of use. They do not have a special effect on the fundamental design of the supporting frame.

Option number 1 - transformers

Despite the complexity of the design, transformers are becoming increasingly popular due to their high comfort. The seat has a reclining mechanism. As a result of the transformation, a small bed on suspensions is obtained.

The canopy, as a rule, has a large area and reliably protects both from precipitation and sunlight. For some models, the design of the canopy is supplemented with a visor with the ability to change the angle of inclination. He will be able to protect the seat from the sun's rays falling at an acute angle.

Swing with seat transformation mechanism. Such a mechanism is quite complicated and it is almost impossible to make it yourself. However, if you manage to purchase only the frame of the mechanism, and the rest of the supporting structures swing make it yourself, it will significantly reduce the total cost, while maintaining the highest comfort level

Option number 2 - children's swing

The main emphasis in design development is on safety. All-metal suspensions made of pipes do not allow swinging obliquely, preventing hitting the racks. The seats are equipped with holders so that the child does not fall out during the download.

Sizes are also reduced, adapting to the small stature of children. The seat, most often, is single, so that there are no conflicts, the swing is made double or triple.

Two swings, almost, for the price of one, will save you from endless complaints and quarrels over the order of riding. And even a novice home master can handle self-assembly of such a design.

Option number 3 - spherical models

Traditional designs with seats in the form of a bench have a lot of advantages, ranging from simplicity of design to good capacity. However, when it comes to design and unusual constructive solutions, then a spherical swing is unrivaled. In stores, such products are called hanging chairs, and they are most often designed for one person.

At home, you can make a slightly larger chair. In this case, the shape of the seat can vary from a sphere to a drop. An arcuate rack is used as a bearing element.

With due skill, it is not too difficult to weld a frame for a suspended spherical swing. However, it is necessary to have devices for bending the metal profile, since most of the elements have a curvilinear shape.

The compact models use a ring-shaped base located exactly under the spherical seat. Larger, teardrop-shaped, designed for two or more people should have a more powerful stationary rack. It can be an independent structure or be part of a structural element of the building.

Numerous cushions or small specially tailored mattresses are folded onto the seat to increase comfort. To protect from the sun, the upper part of the sphere is draped with a cloth.

You can sit on such a seat only reclining, this provides for some difficulties when landing and getting up. So such models are suitable only for people without any problems with the musculoskeletal system.

Option number 4 - hammocks

Popular, in recent times, a variety that provides for the location of the lying on the seat. Hammocks swings have their own design features.

The seat consists of a metal frame with a fabric stretched over it. This, in itself, provides a fairly high level of comfort. Such swings do not have a back or it is located at a large angle in a reclining state.

Hammock swings provide the maximum level of comfort and are quite easy to manufacture. However, you should not simplify the design as much as possible and use branches and tree trunks instead of bearing racks. They have high flexibility and rocking will be uneven and dangerous.

Swing installation method

According to the installation method, the swing can be stationary or mobile. In the first case, the bearing elements of the swing can be rigidly attached to the foundation. As a rule, such products have a bulky design, are characterized by high strength and reliability.

Mobile models have racks in the form of trapezoids or triangles connected by transverse elements to give the structure spatial rigidity. Most often they are intended for children and have restrictions on the maximum load.

The main advantage of mobile models is the possibility of their location anywhere in the garden, depending on the current preferences of the owners.

Materials, tools, drawings

The simplest design of a metal outdoor swing is a frame of two A-shaped posts connected by a crossbar. Suspensions are attached to it through bearings, to which, in turn, a seat is attached.

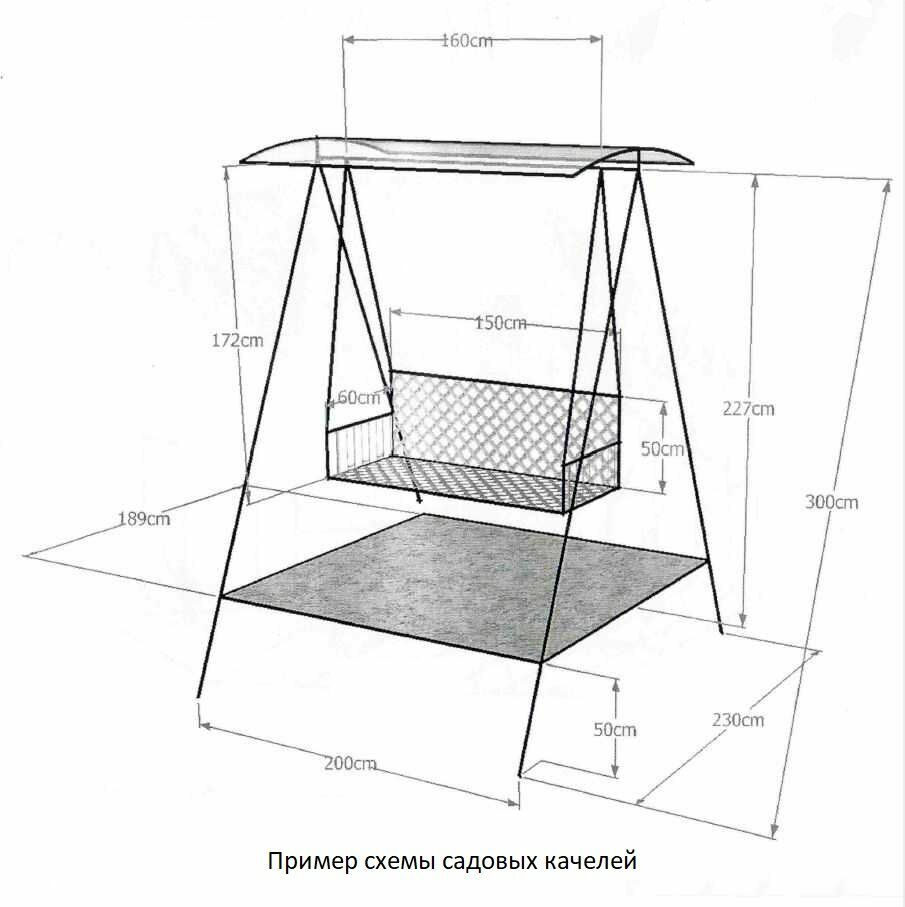

Schematic diagram of an A-post swing with dimensions. It may well serve as a guide to self-production, providing a wide range of consumables and mounting methods.

Despite the apparent simplicity, the manufacture of such a design has many nuances and requires some skill, as well as a solid set of tools:

- Power tool:

- drill;

- angular grinder - Bulgarian;

- inverter welding machine.

- Hand tool:

- drills for wood and metal;

- screwdrivers, wrenches;

- building level, tape measure;

- Consumables:

- metal profiles of the calculated section;

- boards or bars for the seat frame;

- roof material: polycarbonate, textile (tarpaulin), metal tile, soft tiles (based on thin boards);

- self-tapping screws for metal with plastic washers for fixing polycarbonate, nuts, bolts, washers.

Since dynamic loads act on the supporting frame of the swing, it is better to make all connections one-piece using electric welding. Its use is much faster and more reliable than using nuts and bolts in collapsible connections. It should be noted that when loosening the thread will relax, causing backlash.

Used as the main material of manufacture rolled metal. It is necessary to carefully select the type of profiled rolled products, since not only the strength and durability of the structure depends on this. By choosing a thick-walled metal, the master will significantly complicate all work processes. Since such material is much worse for drilling, cutting and bending.

For the uprights and the crossbar of the swing, designed to withstand the weight of two or three adults, a pipe with a diameter of 70 mm is enough. It is advisable to make the seat frame from pipes with a diameter of 40 mm. If a chain is used for suspensions, then the thickness of the link must be at least 5 mm.

Instructions for the construction of a swing

Consider the sequence of actions presented in the diagram of the option in more detail. First you need to use a grinder to cut profiled pipes for racks 3 m long (4 pcs.). The total height of the swing will be somewhat lower, but it is necessary to have a supply of pipes for concreting.

Then 4 pipes 2 m long are cut for the crossbars that create stiffeners. In the future, they will be fixed around the perimeter and create a base on which the swing will rest.

The ends of the racks on one side are cut off by a grinder at an angle of 30 and welded together. The crossbar can be welded to the uprights at the end, but the connection into the groove is much more efficient, etc.

After that, stiffeners are applied to the bottom of the racks to form an isosceles triangle. They mark the cut angle on them, cut it with a grinder and weld it. The upper horizontal bar is cut out and welded to the top of the rack.

The bench will have a back and a seat made of wooden blocks with a sectional area of 30x30 (30x70, 30x50) mm. The workpieces must first be sanded with sandpaper, angular grinders with appropriate nozzle or machine thicknesser. Suitable for wood protective covering before the start of installation work. Thus, the entire area of the workpiece will be processed.

In the frame of the bench, through holes of small diameter are drilled from the inside. Through them, screws with self-tapping screws, the rails will be screwed to the frame of the bench

The seat frame is assembled. In the presence of a pipe bending machine, the arcs for the armrests are bent. If there is no such device, welding from several parts is allowed. Then the rails are screwed to the frame in increments of 20-30 mm.

Holes are drilled in the upper crossbar, where bolts with hooks are inserted that fix rymny nuts or welded on. Chains are threaded into the hooks, which are attached to the frame of the bench with a carabiner.

Using carabiners to attach the bench has an added advantage. You can adjust the height, as well as the angle of the seat directly during the operation of the swing

Sections of a profiled pipe are welded to the upper crossbar at an angle of 15-20 degrees. They will serve as a supporting base for the roof.

Next, wooden slats of the appropriate size are screwed to the pipes, on which the roofing is laid. To protect against corrosion, the metal is painted in 2 layers with oil paint.

After that, small pits 50 cm deep break out in the ground. Snacks and the bottom is laid out with roofing felt or other similar material. It will act as a formwork and will not allow moisture to soak into the ground too quickly.

The swing legs are lowered into the recesses, after which the space is filled with rubble stone and poured with a liquid cement-sand mortar. It remains to wait until the concrete hardens and you can use homemade.

Conclusions and useful video on the topic

How to independently make a metal swing with decorative elements:

Independent production of a swing from metal profiles is not very difficult for a person who has even basic skills in working with metal. The main thing is the presence of the appropriate tool and accuracy in the performance of electric welding.

If desired, the design can be decorated with various decorative elements imitating forging. They can be purchased at building supermarkets or made independently from 8-10 mm wire by cold bending.

If you have already had to make a metal swing with your own hands, please share your own experience with our readers. Write your comments, upload photos of your own swings to the comment block. There you can also ask questions of interest to our experts on the topic of the article.