Suspended ceiling structure turned out to be easier to install and cheaper to manufacture. It has been used for a long time and has become an alternative to leveling ceiling surfaces with plaster or putty mortars.

If earlier they used mainly wooden building materials for this - boards, plywood, fiberboard - today they have not been replaced by cheap drywall (gypsum plasterboard). Before you make a plasterboard ceiling, you need to understand the technology of its formation.

The content of the article:

-

The nuances of installing a plasterboard ceiling

- Pros of plasterboard ceiling

- Cons of plasterboard ceiling

-

Preparatory stage

- Room preparation

- Design

- Calculations for the necessary materials

- Drawing markings on the ceiling and walls

-

ceiling installation process

- Frame assembly

- Strengthening heat and sound insulation

- Drywall installation

- Finishing finishing

- Frame for a multi-level plasterboard ceiling

The nuances of installing a plasterboard ceiling

The plasterboard suspended ceiling got its name because it does not touch the base ceiling surface, but is located at a distance from it. On the one hand, it is attached to the walls of the room, on the other hand, on stands or special fasteners, which themselves are fixed to the base ceiling.

The next nuance is the choice of drywall. Behind the scenes, this sheet material is divided into 2 groups: wall and ceiling. They differ from each other in thickness. The first group includes sheets with a thickness of more than 12 mm, the second - 12 mm or less. But there is one moment.

If the construction of a drywall construction is done by hand, and besides alone, then it is better to choose a material with a thickness of no more than 9.5 mm. This will not only make the installation process easier, it is also a good money saver.

The third nuance concerns the type of plasterboard ceiling. It can be single-level or multi-level. The first is simpler than the second, but the latter is not so complicated either. We must first learn how to make a single-level, and then move on to more complex structures.

There are a lot of nuances for installing a plasterboard ceiling. This also applies to the assembly of the frame, and the laying of drywall sheets, and their fastening, and the application of putty mortar.

Pros of plasterboard ceiling

It was said that it was not necessary to repair the base ceiling. Drywall covers it completely. The only thing that is recommended to do with the base surface is to repair large and serious defects with a repair mortar and cover the entire ceiling area with a primer. It will take a little time, the cash costs will be scanty. But the ceiling will not crumble, and there will be no debris left on the drywall.

Between the drywall and the base ceiling, a space is formed where communication engineering networks can be laid: pipes, cables, wires, etc. For them, it is not necessary to ditch building structures, they can be placed in any direction. However, they will not be visible.

Drywall has a good lifespan. Manufacturers give a period of up to 30 years, but with proper operation it will last longer. It is easy to repair - putty and paint. Can be wallpapered.

It is easy to embed lamps into it. From it on the ceiling you can make various decorative elements of any shape - this will decorate the room.

Cons of plasterboard ceiling

The biggest disadvantage of drywall is that it is afraid of high humidity, and even more so water. Under their influence, the material becomes unusable. It is impossible to repair such a building. It needs to be replaced with new sheets. Therefore, in wet areas, such as a bathroom or kitchen, it is better not to install drywall. Moisture-resistant materials are suitable here: plastic panels, stretch ceilings and others.

Suspended design reduces the height of the ceilings. Therefore, if this parameter is small, then you should not do it.

If it is decided to erect a plasterboard ceiling structure in new buildings, then it is not recommended to do this immediately. The natural shrinkage of a high-rise building will take some time - usually a year. If the plasterboard ceiling structure was nevertheless erected, then it will be damaged within a year: cracks, expansion of gaps, expansion of joints between the wall, and so on.

Preparatory stage

This stage is important because it includes all the procedures that precede the installation process. The better the preparation is carried out, the faster, better and without additional costs the installation will take place.

Room preparation

Ideally, if the room is completely vacated. So it will be easier to move around the goats or scaffolding and flooring, to carry large sheets of drywall. Free space increases the speed of ongoing construction operations.

If this is not possible, then you will have to move the furniture from one corner (side) of the room to another. Some craftsmen group the furniture in the middle of the square and work around it. But all these options create inconvenience. Therefore, the advice is to take out things and furniture.

It is important to prepare the surface of the base ceiling. The fixtures are removed, the exfoliated parts of the plaster or other decor are removed. If mold-infected areas are present, they are treated with special compounds. Colonies of microorganisms must be dealt with seriously. They must not be left under a suspended plasterboard structure.

Design

Some complex project is not needed here. It is necessary to create a plan on paper, on which the structures of the new ceiling will be clearly visible. This mainly concerns the frame with the location of all its parts and assemblies.

Here it is necessary to indicate the location of the lamps, because they need to lay electrical wiring. Accordingly, indicate on the diagram how the cable will be laid. Maybe the ceiling will be illuminated, then this moment should be taken into account and indicated in the project.

Calculations for the necessary materials

If it is decided to make a single-level ceiling, then the amount of drywall will be equal to the ceiling area. Therefore, it is necessary to measure the length and width of the room and multiply the resulting values. Now the number of GKL sheets is calculated. Their standard size: 1.25x2.5 m. Therefore, the area will be equal to - 3.125 m².

For example, the area of the room is 18 m². This means that to cover it you will need: 18: 3.125 = 5.76 pieces of drywall sheets. We increase this figure to a whole larger one. That is, you need 6 sheets of drywall.

The number of frame parts is calculated:

- Guide profiles that are installed around the perimeter of the room. Their number is equal to the sum of the lengths of all sides of the room.

- Ceiling profiles form a grid on which the GKL sheets will be mounted. Usually a lattice is created with cells of 60x60 cm, this is the same as 0.6x0.6 m. For example, if the lengths of the sides of the room are 6 and 3 m, then in the longitudinal direction it is necessary to lay 4 rows of length 6 m each, in the transverse 9 3 m long. If we sum up all the lengths, the total length will be: (4x6) + (3x9) \u003d 51 m. Usually the length of the ceiling profile is 3 m, which means you need: 51: 3 \u003d 17 things.

- Direct hangers. They are located only under the longitudinal ceiling profiles and from each other at a distance of 50-60 cm.

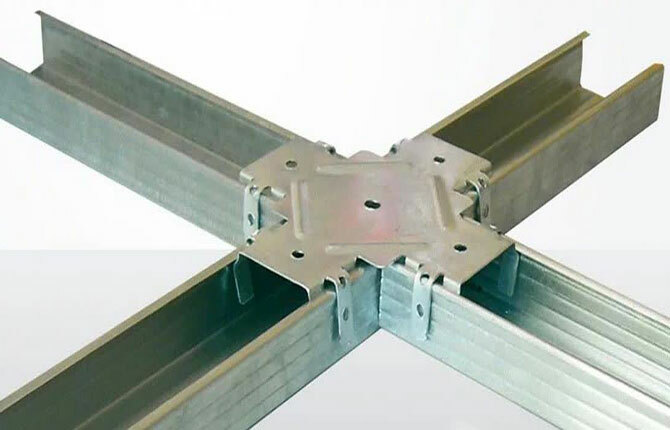

- If the longitudinal and transverse profiles are connected by crabs, then their number is equal to the intersection points of these profiles. This can be calculated by looking at the project.

Drawing markings on the ceiling and walls

First of all, the installation location of the guide profiles is determined. To do this, measure the height of the ceilings in the corners of the room. Choose the smallest size and lower 5 cm from the ceiling. This point is a guide to draw a horizontal line on all walls, for which a laser level is used.

Now, in accordance with the plan on paper, it is necessary to draw lines for the location of longitudinal ceiling profiles on the surface of the base ceiling. On them, every 50-60 cm marks are applied for direct suspensions. This completes the markup, and, accordingly, the preparatory stage is completed.

ceiling installation process

There are 2 steps here:

- frame assembly;

- drywall installation.

Frame assembly

Guide profiles are superimposed along the lines drawn on the walls and fastened with dowels and self-tapping screws to the walls:

- applied;

- every 25-30 cm drill holes are drilled in the wall directly through the metal;

- dowels are inserted;

- self-tapping screws are screwed into them.

Further, according to the marks on the ceiling, direct suspensions are mounted in the same way as the guides. Fasteners are the same - self-tapping screws on plastic dowels.

It is now necessary to install and fix the longitudinal ceiling profiles to the suspensions. Since the length of the room is 6 m, you need to connect 2 profiles together. This can be done in many ways. One of them is shown in the photo below. Here, an insert is made from the profile, which is inserted inside and fixed on the outside with small self-tapping screws, which among the masters are called "bugs".

First you need to insert the ends of the ceiling frame element into the guides. Here, fix them with bedbugs - 2 fasteners on one side. Then lift to one of the suspensions and temporarily fix to it. This is done with all longitudinal elements.

Further, 3-4 rows of strong threads are stretched across the room along the guides on the walls. They will indicate the horizontal plane along which it will be necessary to align the installed longitudinal elements of the frame.

The latter are removed from temporary fasteners, lowered to stretched threads and attached to straight hangers along the entire length. It is difficult to do this alone, so you will need an assistant.

The next step is the installation and fastening of the crossbars. To do this, the prepared profiles are cut into segments with a length equal to the side of the frame cell. They are installed in the designated places and attached to the longitudinal elements with crabs, as shown in the photo.

Strengthening heat and sound insulation

It is necessary to insulate the ceiling or make a soundproof layer on its surface at the stage of creating the frame - before it will be necessary to mount the ceiling profiles. That is, the guides are installed on the walls, direct suspensions are attached to the base surface.

Any porous or fibrous materials are suitable for insulation and soundproofing. More often they use mineral wool in rolls or mats, polystyrene foam boards. The latter is the easiest. They are simply glued to the ceiling with a special adhesive composition. So that direct suspensions do not interfere, through slits are made in the plates, where the suspensions are inserted.

With mineral wool, you have to tinker a little. Slots are also made on it, but it cannot be attached to the ceiling. Therefore, it is attached to suspensions by inserting a pin or wire into their holes. After assembling the entire frame, it will lie on it.

Right now they are laying the wiring. It should not remain under the heater. The reason is that if you need to make a replacement or repair of wires, you will need to partially disassemble the plasterboard ceiling, while not touching the heat-insulating material.

All wires and cables are laid only in plastic corrugation. The ends of the cable are brought out exactly at the place of installation of the fixtures.

Drywall installation

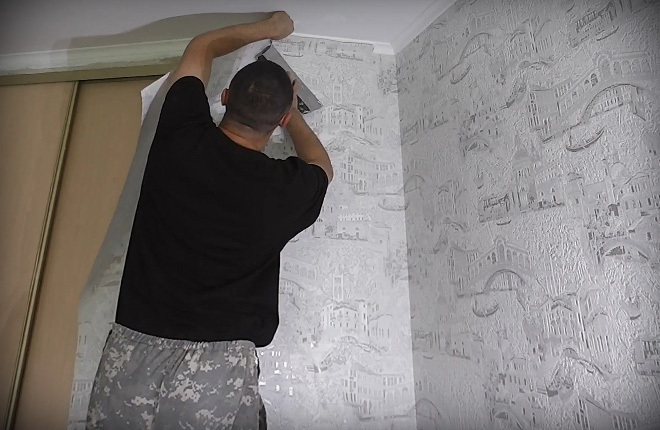

The next item in the step-by-step instructions affects the installation of drywall. It is difficult to do this construction operation alone with your own hands, because you have to lift a large sheet under the ceiling. Therefore, an assistant is needed.

Installation of drywall can be done from any corner of the room.

The sheet is pressed against the walls and attached to the profiles with black screws. Their length is selected taking into account the thickness of the GKL sheets. Please note that the material should lie down so that its edge, which is not near the wall, should lie on the ceiling profile exactly in the middle. On the profile, 2 adjacent drywall sheets will be joined.

How to properly fix drywall:

- self-tapping screws are screwed around the perimeter of drywall every 10-12 cm;

- on intermediate profiles - every 30-40 cm;

- the screw point should be located from the edge of the sheet at a distance of 1.5-2.0 cm;

- the fastener cap should be recessed by 0.5 cm, then it will be covered with putty.

In this way, all drywall is laid and fastened. If necessary, if the free area on the frame turned out to be less than the GKL area, the latter is cut to the required size and shape. Fortunately, this is easy to do with a sharp knife. This completes the installation of the plasterboard ceiling.

Finishing finishing

Drywall sheets today are produced with a chamfer. This is an oblique cut at the edges. It is necessary for the fact that when joining 2 panels, a groove formed between them. It is filled with putty with a spatula, either a sickle tape made of a polymer or a perforated paper tape is applied on top. Both of them perform the functions of a reinforcing frame.

The tape is laid on a fresh putty, that is, in a wet way. It is slightly melted and another putty layer is applied. It is the groove and the tape that hold the thick layer of leveling material on the ceiling.

Drywall itself is a flat material. But when mounting on a frame, you can’t do without small curvatures. And although they are not clearly visible, under certain lighting, especially from ceiling lights, the curvature of the surface will be clearly indicated.

Therefore, the plasterboard suspended ceiling is completely puttied, sometimes in several layers. But before that, it is covered with a primer. After drying, each putty layer is sanded with fine sandpaper and again treated with a primer. This must be done with the last front layer.

Now you need to wait for the putty on the ceiling to dry completely. The next step is finishing. Usually the ceiling surface is painted, rarely covered with wallpaper.

The last operation is the installation of fixtures. Previously, if these are built-in light sources, then holes are made under them in drywall for their size and shape. If the lighting fixtures are of an overhead type, then small point holes are made for the cable. Holes must be made before the plastering of the ceiling.

Frame for a multi-level plasterboard ceiling

A multi-level plasterboard ceiling is a more complex structure in which one nuance must be taken into account. The frame is assembled in the form of a stepped structure. But there is an easier option, although you will have to level, in this case, plaster, a section of the base ceiling.

The frame is built along the edges, near the walls of the room, in the middle there is a base ceiling, which will need to be leveled. Therefore, the frame is made first. The technology is almost the same as for single-level models:

- Guide profiles are installed on the walls along the applied horizontal perimeter.

- It is better to draw lines on the base ceiling along which direct suspensions will be mounted. If a figured ceiling is made, that is, with curved inner ends, then the line must exactly repeat the figure. If it is a straight line, then there are no problems with its application.

- Install direct suspensions on the base ceiling.

- Ceiling profiles are attached to them in one horizontal plane.

Now you need to form the inner end of the level. The complexity of its manufacture depends on the height of the drop. The larger the latter, the more difficult - more material will go away.

There are different technologies for forming ends. One of them is to use guide profiles. One is attached to the base ceiling, the other is lower at a certain distance using any drywall mounting elements.

You can make jumpers from direct suspensions, use ceiling or wall profiles. Here it is important to accurately observe the distance between the guides and securely connect them to each other. Subsequently, the butt will need to be sheathed with a strip, carved from drywall sheet.

The rest of the frame structure is also sheathed with drywall. But the free area of \u200b\u200bthe base ceiling will have to be leveled with plaster. And this must be done before installing drywall. How to do it right:

- The base ceiling surface is freed from areas that do not adhere well to it.

- The primer is being made.

- The plaster layer is applied after the primer liquid has dried.

- After the plaster has dried, putty is applied in several layers, each of which is primed.

- The last putty layer is sanded and primed.

- Painting, wallpapering, installation of moldings, skirting boards and other decorative elements.

Usually masters work in parallel. That is, they built a frame, go to the plaster. While it dries, drywall is mounted. Putty is applied to the entire ceiling surface, including drywall. The same goes for the finish.

There are a huge number of options for multi-level ceilings. There are simplified models that do not require large financial and time investments. For example, you can make a plasterboard square or any other figure in the middle of the room on the ceiling. For this, the frame is assembled just for her. The rest of the base surface is leveled and trimmed.

Although working with plaster is not easy. If you do this for the first time, then, for sure, nothing will work. Therefore, if the task is to make a plasterboard ceiling with your own hands, then it is better to choose a single-level design.

The complete absence of wet operations associated with plastering is already a big plus. Applying putty is much easier. It is easily attached to drywall, applied in a thin layer.

Grinding is also a simple process. In addition, a single-level model is suitable for any room in the house. And it's not just the bedroom or living room. But more often such ceilings are made in corridors and hallways.

That is, in small rooms where there is no place for pretentiousness, where the ceiling should not press. A multi-level design in this regard is complex - it occupies a certain space, which is already lacking in small rooms.

Dear readers, I would like to hear your opinion about the plasterboard ceiling in the comments. Maybe someone has already done it with their own hands. Share your experience.