A sleeping place is sometimes considered an important element of the interior of an apartment. A floating bed is an unusual and innovative solution that will give originality to even an ordinary repair. Such a bed will definitely attract attention. The floating design is made by hand, thereby choosing a combination of colors for a specific interior and adding exclusivity.

The content of the article:

- The choice of model and design of the floating bed

-

Schemes and drawings

- rack base

- solid base

- What tools and materials will be needed

-

Step by step instructions for creating

- pallet bed

- metal bed

- Wooden bed

-

How to light up a floating bed

- LED Strip Light

- Duralight

- Installing lighting on a floating bed

The choice of model and design of the floating bed

difference classic bed and soaring in that in the first version the sleeping place is located on 4 legs, which are located at the corners of the frame. In the second, there is only one fairly massive square or rectangular support.

Advantages of a floating bed over a standard one with legs:

- Originality. The effect of a floating bed is hard to dispute.

- Large sleeping area. Soaring type beds are made from a width of 180 cm.

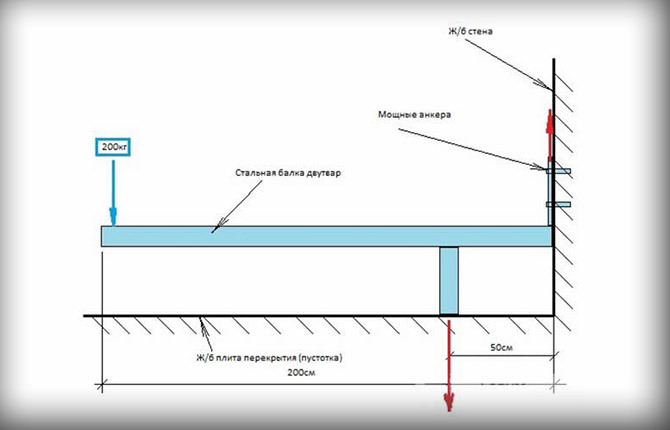

- Strength. Due to the installation of a floating structure on 1 large leg, its stability increases. Reinforce the frame with additional fastenings to the floor and wall.

- Ease of cleaning. Most of the floating bed is above the floor, the space is easy to clean.

- Backlight. When making or purchasing a bed with lighting, an additional source of lighting appears.

Each specific model of a floating bed differs in the structure of the base:

- Secret legs. There are supports, but reinforced and located in the depths of the bed on the supporting beams.

- Reduced base. The top of the floating bed rests on a square or rectangular base that is smaller than the bed frame.

- "Underframe". The floating model is reminiscent of the tables that are often placed in small cafes or eateries. They only have 1 metal leg. The bed has a similar design - 1 reinforced metal support.

- Mounted. L-shaped design, which is complemented by chains attached to the ceiling from the bottom.

- transparent base. Such a model, in fact, is exactly the same as with a rectangular or square base. The difference is that the large leg is made of high-strength glass.

When choosing the final model, a lot depends on the width of the bedroom allocated for the bed, the material of the case and the complexity of manufacturing. Consider the need for additional storage space.

If it is not needed, choose any of the listed models. If hidden drawers are needed, then only one will remain from the list of suitable designs - with a rectangular or square base, always with a lifting mechanism.

Schemes and drawings

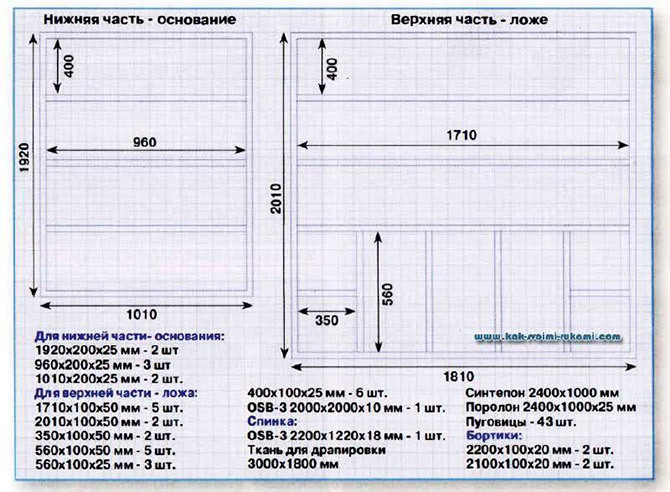

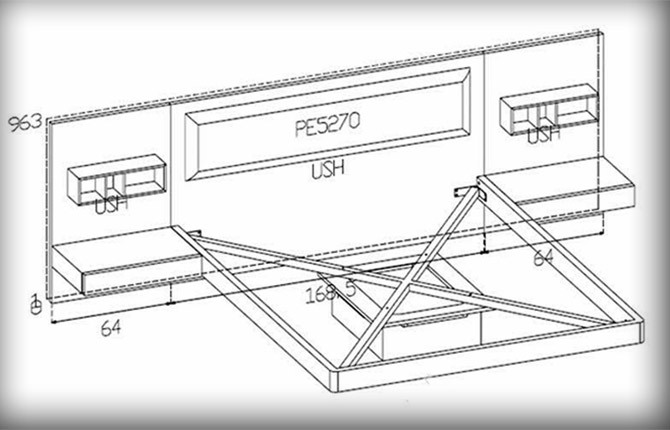

When making a floating bed with your own hands, more often the choice falls towards a model with a large drawer leg with a lifting mechanism. This structure is made mainly of wood with additional reinforcement, which simplifies the task of preparation and assembly.

Drawings of the bed of this model are available both with and without a mechanism. Also choose lighting options. When choosing a ready-made scheme for a floating bed, it is important to pay attention to the presence of an additional box at the base of the bed.

There are 3 types of structures:

- Rack. Sturdy base-frame, consisting of transverse lamellas (convex or concave slats).

- Solid canvas. A solid sheet of DPS or other similar material is laid in the frame. Although this type of base is outdated, it is still often used in the manufacture of beds because of the simplicity of the design.

- Orthopedic. This type of base is similar to the rack. However, the materials of the lamellas differ. This type requires more flexible ones, such as birch or beech (due to increased stress on parts).

The base of the bed is an important part of the floating bed. Contrary to popular belief, the comfort of sleeping does not depend on the frame, because there is a mattress on top, which is just designed to create a comfortable sleep. As for the base, it affects:

- mattress location;

- unwanted sounds from the structure, such as creaking;

- air permeability of the mattress;

- strength.

rack base

T. to. the orthopedic base is similar to the rack, considering it, they are combined into one group. Main advantages:

- reinforcement of the mattress due to flexible slats;

- correct load distribution;

- extended service life;

- in case of breakage of the lamellas, they are easy to replace;

- Improved mattress ventilation

Basically, for 1 bed with a length of 160 cm, from 15 pieces are installed. flexible rails.

solid base

Represents a one-piece construction, made under the mattress.

Benefits of this foundation:

- simple manufacturing when designing a floating bed;

- affordable price;

- help in the treatment of certain diseases of the spine (due to increased stiffness).

In comparison with the orthopedic rack base, this type has many disadvantages:

- poor ventilation of the mattress, even with special holes;

- all the distinctive qualities of an orthopedic mattress will not be felt on a solid base;

- in case of breakage or deformation, a complete replacement of the base is necessary.

Regardless of the chosen base, it is installed both with a lifting mechanism and without it.

What tools and materials will be needed

The main material for making a floating bed is wood. However, each breed has properties that are taken into account when designing. For a floating bed, a wooden frame is more often used.

Wood is divided into 2 main groups - hard (oak, maple, beech, birch, ash and walnut) and soft (spruce, thuja, pine, cedar, aspen, alder, linden). There is a separate subgroup "superhard". It includes boxwood, hornbeam, dogwood and yew. The latter species of trees are rare, the cost is higher than that of soft and hard trees combined.

The best wood for making a floating bed is solid wood. However, it is expensive. It is better to purchase this material with full self-confidence, because due to your own inexperience, it is easy to spoil an expensive timber frame.

To save the budget, buy chipboard. However, this material will never be compared in strength with natural wood.

If you focus on wear resistance, then pay attention to the following breeds:

- Pine. Due to the high resin content, this species is not subject to decay, but is easy to process. This breed is soft, but strong, so it will be a good material for making a frame.

- Spruce. This type of wood is in many ways similar to pine, but it is prone to cracking.

- Beech. A flexible type of wood that is often used for load-bearing parts.

- Oak. The best material that combines strength and resistance to decay. It is used both for the construction of load-bearing frame parts and decorative elements. Oak is difficult to process.

Almost any floating bed is not difficult to make both from wood and metal. It is better to use specially prepared pipes with a cross section.

Regardless of the model and material of the frame, other components of the floating bed, they prepare a list of what is necessary for design:

- marking tools (tape measure, ruler, marker);

- drill driver;

- clamps and special clamps;

- fittings for fastening;

- additional elements to strengthen the floating structure;

- jigsaw for wooden parts or a hacksaw for wood;

- grinder for working with metal, if such parts are present in the scheme;

- facing materials.

In addition, use a jigsaw or drill. It is necessary to stock up on spare bits and files, because with prolonged use they quickly become unusable.

Step by step instructions for creating

Despite the visual complexity in the manufacture of a floating bed, in reality everything is simpler. Already at the stage of creation, you can understand many details, subtleties of the design.

Before you make a floating bed with your own hands, consider 3 models that even a beginner can make with step-by-step instructions:

- Pallet bed. The advantage is the availability of materials, the finished frame for support. But for a small structure, they do not use it, because the pallets will be visible at the entrance to the room and will not create a floating effect.

- Floating metal bed. It will turn out expensive, beautiful, durable. Without skills in working with metal, welding profiles, the appearance of furniture will immediately give out the inexperience of the master.

- Bed from a tree with the lifting mechanism. It will turn out comfortable, environmentally friendly, with storage space.

pallet bed

Pallets are made from pine, linden or birch. These rocks are well suited for creating furniture. Each block has a high load capacity, making it a good building material for a bed.

Pallet furniture looks extraordinary and attracts attention. Quite often it is used in the design of the "loft" style.

When constructing a floating bed from pallets, they take a drawing of podium furniture as a basis, only the lower part is made so that there is one large leg from a pallet. In addition to the previously indicated list of necessary materials, for the manufacture you will need:

- pallets (their number is calculated according to the scheme or drawing);

- primer for wooden surfaces;

- wood finishing paint;

- grinder or sandpaper of different grits.

To begin with, pallets are prepared, since they are sold without processing at all or with the very minimum, for example, from internal small knots:

- Remove all dirt from pallets.

- Ventilate to eliminate excess odors.

- Dry the pallets on all sides.

Start processing materials:

- Using a grinder with a coarse nozzle, remove the remaining knots.

- A more granular nozzle or sandpaper level the surface, giving it smoothness, so as not to be injured when the skin and wood come into contact.

- According to the drawing, each pallet is adjusted to the required size using a saw or a jigsaw.

- Each pallet is treated with a primer, leaving it to dry completely for 24-30 hours.

- Prepared pallets are painted with special paint for wood.

After preparing all the materials, proceed to the installation of the floating bed. Assembly is carried out from the bottom up:

- The base-leg is assembled first. The prepared number of pallets is fastened with self-tapping screws, or at the same time with them and special metal corners, which will further strengthen the structure.

- The bed base is being assembled. According to the scheme, it should turn out to be larger than the mattress, which will be located on top. On average, for a double bed, at least 4 pallets are taken, fastened both to each other (this will be the base), and with an already prepared leg.

- The final stage is the installation of the headboard. They make a floating bed without this element. However, in addition to additional strength, the headboard is used as bedside shelves. There are several options, but the most popular is that pallets separated along the length are attached to each other and to the finished frame. Thus, the floating bed acquires an L-shape.

- Additional lighting. If desired, install an LED strip inside the base of the bed, visually enhancing the floating effect.

metal bed

The model of a floating bed made of metal is a metal base for a bed, installed on one reinforced leg, like geridon tables.

Metal is stronger than any kind of wood, even the hardest. A bed made of this material will be more wear-resistant. However, when installing with your own hands, they face some difficulties. For enhanced fastening of parts to each other, it is better to use welding, when working with which safety precautions are observed. Work is carried out in a separate specially prepared room.

In addition to a set of tools and accessories for mounting a floating metal bed, you will need:

- profile pipes, the number of which is calculated according to the scheme;

- facing materials for the headboard;

- grinding machine with nozzles for metal;

- varnish against corrosion;

- a sheet of plywood for the manufacture of a solid base for a berth.

Metal is a durable material, so prepare spare bits, drills and threading discs, as they can quickly become unusable or break.

After preparing materials and tools, proceed to installation:

- Following the step-by-step instructions, make a frame using a welding machine or using special profiles and self-tapping screws.

- Assemble the headboard in the same way as the base.

- Joints must be sanded, and then treated with varnish to protect against corrosion.

- Connect 2 finished parts.

- Make the central leg, which will be under the base.

- Mount all parts of the bed.

- Install a solid canvas for a berth on the finished frame.

- Supplement the headboard with separately prepared facing materials.

When assembling, pay attention to the protection of the floor. When working with metal structures, it is easy to damage the flooring. To enhance the soaring effect, select the paint to cover the frame to match the color of the floor.

Wooden bed

The most popular furniture material is wood. It is often chosen because of its lightness, because, for example, a welding machine is needed for metal beds, and there are few models with a transparent glass base.

The best floating bed made of wood is considered to be with a rectangular or square base leg (will serve as additional storage space). Less often it is supplemented with a lifting mechanism.

To make a floating wooden bed you will need:

- boards for assembling the frame, bed frames, headboards;

- plywood for a solid bed base;

- lamellas and fittings for the orthopedic base;

- facing materials;

- primer for processing wooden surfaces;

- varnish or paint for wood finishing;

- lifting mechanism.

Having picked up the materials, proceed to the assembly of the floating product:

- First, assemble the base box, which will serve as a storage box. Make a choice of rectangular or square shape. But for a greater floating effect, it is better to choose the first one, because it will be narrower.

- Strengthen the box with metal corners and additional bars.

- Collect base. Prepare the boards according to the drawing, connect them together, not forgetting the box-box below.

- After assembling the frame, combine it with the canvas of the bed.

- Make the head of the bed.

- After assembling the individual parts, treat them first with a primer, then (after complete drying) with paint or varnish.

- After the final layer of the coating dries, assemble all the individual parts together, remembering to install the lifting mechanism on the frame of the sleeping bed.

- After completing the installation of individual elements, install facing materials for the sides and headboard.

The headboard is made both classic wooden and soft. To do this, additionally purchase:

- fabric for covering;

- foam rubber;

- furniture stapler.

The soft headboard is complemented with decorative elements in the form of matching buttons or large rhinestones.

How to light up a floating bed

Illumination is able to give uniqueness to any object in the apartment. But it is with a floating bed that she looks more spectacular.

By itself, the illusion of soaring is obtained due to the hidden legs and furniture finishing to match the flooring. However, additional lighting in muted colors makes it as natural as possible.

In building mass markets and online stores, a selection of ribbons and garlands is presented. Any use as a backlight for the bed. For furniture decoration, one-color tape is often chosen, as well as with the ability to switch to other colors. 2 main types of lighting for the interior and individual elements - LED and duralight.

LED Strip Light

LED strips are now popular for extra lighting. They are used to highlight zones in an apartment or house, public places. This type of lighting has the following advantages:

- Flexibility (the LED strip is quite soft, and it can be easily bent in any direction).

- Safety (due to low voltage and the absence of heating diodes to dangerous limits).

- Ease of installation (due to the low weight of the tape, it is easy to install on double-sided tape).

- Remote control (most lamps and ribbons come with a special remote control).

- Compactness (LED strips are quite thin, and they are easy to install at the joints so that only their glow is visible, and not the diode base).

- Assortment (on any marketplace it is easy to find a tape of the right size and color).

- Long service life (LED lamps have a long service life compared to classic lighting with incandescent lamps).

- Profitability (due to low power consumption).

Of the minuses, one is singled out - this is the cost. It cannot be called high. But in comparison with other types of lamps, it is certainly larger. However, when buying lighting, the price is offset by the service life. When buying an LED lamp, instead of a simple one (incandescent), the next replacement will be required after at least 3 years.

Duralight

This type of lighting first appeared in 1987. in Japan and almost immediately became popular all over the world. Often it began to be used to decorate streets and houses.

Duralight is a wire, inside of which there are small lamps. When this type of garland first appeared, there were DRLs (arc mercury lamps) inside. However, over time, they were completely replaced by LEDs. So now duralight is, in fact, an LED strip enclosed in a dense transparent wire.

Differences between such lighting and LED strips:

- increased voltage (for duralights, power is supplied at 220 V);

- reduced flexibility (due to the top sheath wire);

- safety (the safety level of the LED strip is higher due to the lower voltage).

Installing lighting on a floating bed

Having chosen the type of lighting, proceed to installation. For a floating bed you need:

- Determine the required length of the tape by marking the places of preliminary fastening.

- Choose the connection option and location of the power supply.

- It is best to run the backlight under the side trim so that the light is directed downward or slightly to the side, and the tape itself is hidden.

- Degrease the surface where the lighting will be attached. The composition of the degreaser is selected so as not to damage the coating of the finished product.

- Install the tape using double-sided tape or a special adhesive coating on the garland itself.

- Connect the switch to the power supply. You will need a soldering iron, however, this depends on the type of tape (sometimes the clips are already soldered).

- According to the selected ribbon, set a permanent muted glow with classic colors or presented in RGB mode.

- In the presence of modes, check for frequent blinking or gradual fading.

Despite the visual complexity of the floating bed, even a beginner who does not have special skills can make it. The result in any case will be better than all expectations. Such unusual furniture looks extraordinary, modern and attracts attention.

And what did you make the stand in the floating bed from, what did you cover the wood or metal with? Share the link on social networks and bookmark the article.