Bedroom furniture in the house should be reliable and durable. The frame of the bed, sofa and even chairs of good quality are made of oak or hardwood timber. But you can make a bed out of metal.

Oak, larch and beech will cost a lot, and besides, you need to have the appropriate qualifications so as not to spoil the expensive material. With metal, everything is simpler, it is also more accessible in processing, and any do-it-yourselfer can work with it.

The content of the article:

-

Drawings and implementations

- Single models

- Baby

- Double

- What tools and materials will be needed

-

Step by step instructions for creating

- frame

- headboard

- Bed assembly

- Final processing

- How to improve the design of a metal bed

Drawings and implementations

The first step is to choose the right project. In most cases, a do-it-yourself metal bed is made from a steel corner, a ½” or ¾” profile or water pipe. It all depends on the size, design features of the bed.

Only the main load-bearing parts will be made of metal:

- Mattress frame.

- Backs. It can be made from a round pipe or a square profile.

- Supports and additional stiffening ribs.

You can easily come up with a project yourself according to your own patterns and sketches. The use of metal ensures that the bed, whether single or double, is strong and durable. But drawings are indispensable. Project documentation allows you to make the bed faster and without overspending material.

Single models

Single beds are rare. Most often, the owners prefer either a one-and-a-half or a double model. For fans of custom-designed home furniture, a metal bed can be made from ¾” pipe sections, as well as lug nuts, angles and tees. All in alloy steel.

For the construction of a single bed, it is necessary to cut blanks from a high-pressure gas pipe made of alloyed metal. Ordinary steel can be used, but the parts will have to be taken to a workshop for additional chrome or nickel plating. In addition, the wall thickness of the gas pipe is more than 4 mm, which means that after cutting the pipe thread, there is a large margin in thickness.

Advantage - furniture made of steel pipes on sleds can be easily disassembled, transported, stored or assembled in the country or in a country house.

Baby

The easiest option is to make a base from a square profile pipe 25x25 mm or 30x30 mm. For the children's version of the back, it is still better to make it not from metal, but to use furniture from an ottoman or from other upholstered furniture.

Design - the simplest rectangular frame made of corrugated pipes, welded end-to-end in the form of a frame. Steel triangles are welded into the corners - kerchiefs made of thick metal 6-8 mm. Welded to the triangles are vertical posts made of 2-inch pipe.

According to this scheme, children's beds are often made in the country house or in a country house, including bunk beds. Unlike wooden furniture, metal frames are not afraid of moisture and easily hibernate even in an unheated room.

Often children's options do loft bed format.

Double

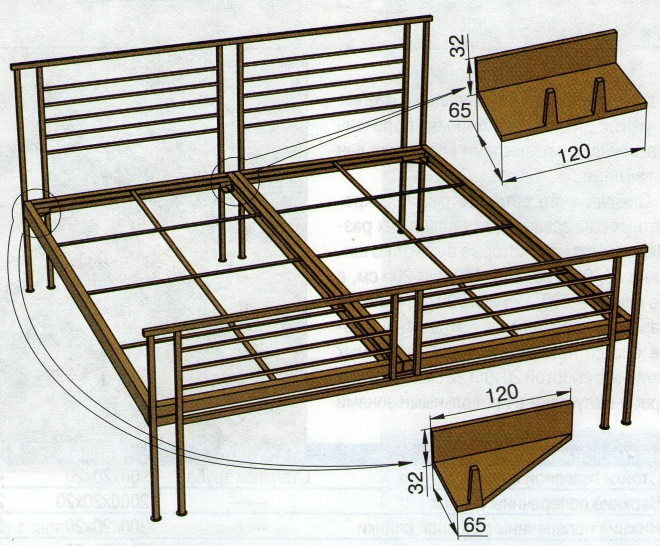

Most often, the bed is made in a double version. Accordingly, for this format, the largest number of models was invented and developed.

For example, a metal double bed can be made of 2 sections.

Each sleeping place is made separately from a profiled pipe and installed on a common steel frame.

Double furniture is often made combined - the frame-frame and backs are made of metal (profiled pipe), and the supporting part for the mattress and legs can be made of oak.

This is one of the most successful models of metal furniture, but it has 2 drawbacks:

- High labor intensity, for example, for each elastic element it will be necessary to make 2 individual fasteners (holders).

- Every detail needs to be customized by hand.

But sometimes the design is simplified - the front back is abandoned, and the elastic elements supporting the mattress are replaced with steel crossbars. This makes sense only if a stuffed mattress will be used on the bed, and not a regular wadded one.

A metal double bed can be assembled from water pipes, spurs and triangles. But if in the single version this method provided a minimum level of rigidity, then for the double version the threaded connection is not strong enough.

The bed can be made, but there is a risk of damage to relatively thin-walled fittings - corners and triangles.

If collapsible furniture for 2 beds is required, then it is best to make it on mounting clamps, which are used to assemble metal scaffolding and shelving.

For those who like Loft style furniture, you can offer the simplest model from a square pipe 70x70 mm and tinted lining.

This is the most reliable and simplest bed option that can be built at home, even without practical experience in this kind of work. The furniture has a solid metal frame, all parts are interconnected by welding.

The bed has no headboards, so the furniture can be easily lifted vertically and leaned against the wall to free up space inside the room. But most often, these beds are used to equip home playgrounds for children on the veranda or covered terrace.

Admirers of the "minimalism" or "techno" style are in high demand for beds with a simple design, rectangular shapes and the absence of decorative elements.

In fact, this is a metal frame (usually a square tube) with a simple headboard.

Collected in the same way floating bed.

With the right selection of furniture and interior, a simple "rectangular" metal bed can look stylish and more attractive than models with wrought or curved headboards.

What tools and materials will be needed

To make a metal bed with your own hands, a square pipe 40x40 mm will be used. Furniture legs will be made from a profile pipe.

The metal frame is heavy and stable, but it will not be easy to transport the finished bed, so it is better to choose an assembly place near the house or apartment.

The construction of the bed requires a minimum set of tools and equipment for metal processing:

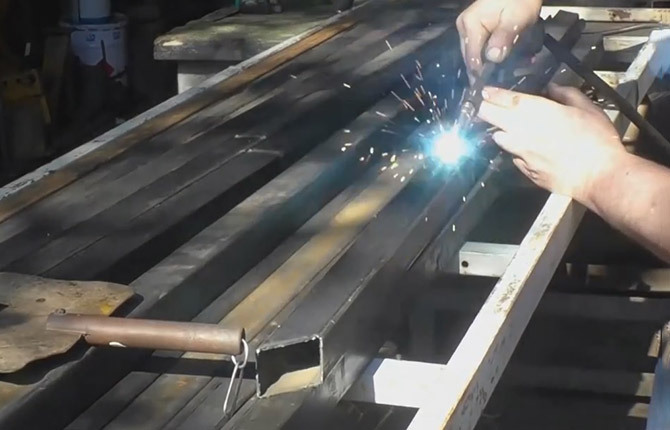

- Semi-automatic welding. The metal of the walls of profiled pipes is thin, so welding (cutting) is performed using a carbon dioxide or argon apparatus.

- Bulgarian with a set of cutting and grinding discs.

- A set of locksmith clamps for precise positioning of workpieces for fillet welds.

- Welding conductor.

- Caliper, tape measure, locksmith ruler and corner.

In addition, you will need to come up with decorative elements with which you can decorate the metal backs. All parts are painted with one coat of primer and two coats of pentaphthalic enamel.

Step by step instructions for creating

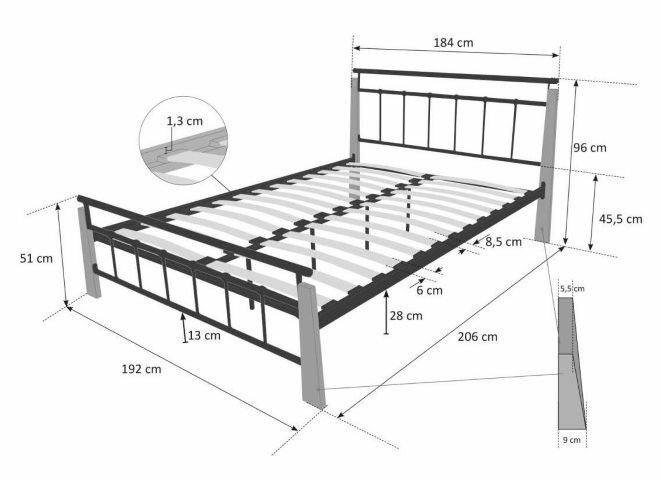

The simplest part of the manufacturing process is the purchase of metal and the delivery of the pipe to the cutting site. Frame frame dimensions - 1650x2000 mm. The height of the back at the head is 800 mm, the height of the legs is 300 mm. Since the maximum size of the largest part is only 200 cm (it will fit into a car), all metal is bought in 210 cm segments.

To make a bed, you will need pieces of metal:

- 2000 mm long and 1920 mm long, 2 pcs. each size;

- pieces of 1650 mm - 4 pieces, 1730 mm - 1 piece;

- for backrests, pieces of 800 mm - 2 pcs., for rear legs of 300 mm - 2 pcs.

We weld the frame in clamps to ensure the quality of the seam and the accuracy of the angle of 90O.

frame

First of all, you need to properly cut the pipe. Metal was purchased for the bed - 8 threads, 2000 mm long (50x50 mm), 4 threads, 2000 mm long (25x25 mm). Since there are pieces of 800 mm in the list of blanks, after cutting there will be pieces of 400 mm and 700 mm.

The most critical part - the frame frame - must be welded from whole segments. The rest of the parts are assembled from pieces. You need to butt weld the pipe. Even the shortest cuts will work.

Clean the seams with an angle machine so that the place of metal welding cannot be determined by touch.

Frame parts cut at the ends at an angle of 45O. This is the most difficult part of the entire metal bed construction project. You need to cut as accurately and evenly as possible. If you try to cut the metal with a grinder, then the exact cut line will turn out only on the upper shelf of the square section. The bottom wall of the pipe will be cut with a small margin of error. And given that the metal of the walls is thin, weld 2 pipes with high quality at an angle of 90O won't work anymore.

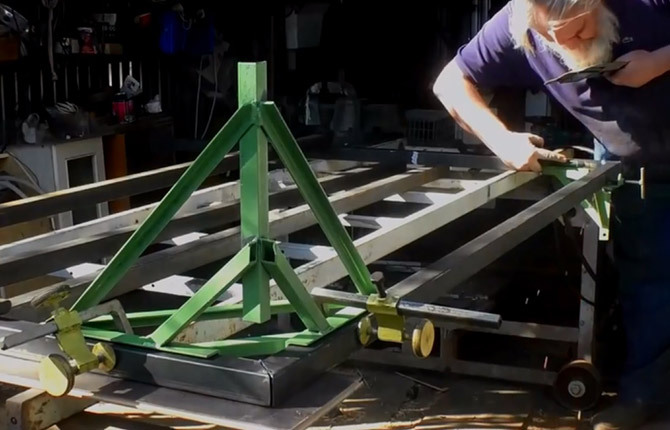

Therefore, a fixture with already fitted edges will be used. In fact, this is a piece of pipe with an edge cut at an angle of 45O and screw lock. It is enough to put the fixture on the end of the workpiece and cut along the edge.

The next step is to weld the frame. For this, 3 blanks are used (2 by 2000 mm and 1 by 1650 mm), 2 clamps and a jig.

The main secret lies in the design of the conductor. This is a complex fixture with special guides on which workpieces with cut edges are placed.

Before welding the metal, the details of the future bed must be aligned so that the blanks maintain an angle of 90O, and they were located in the same plane. We start welding from the inside of the joint.

Moreover, it will be necessary to weld the metal at the seams on the inside at all 4 corners, after which measure the diagonals of the frame with a tape measure. Make sure that the frame of the bed is strictly rectangular. After that, you can proceed to welding the remaining seams in the corners.

During the execution of the first seam, the metal heats up; accordingly, after welding the outer joint, there will be no residual stresses. Simply put, the welded parts of the bed will not lead to the cooling process.

The next step is to weld 2 inner crossbars. To reduce internal stresses, each part is sized to within 0.5 mm.

The crossbars are also fixed with clamps before welding and leveled in a plane. After welding is completed, you need to wait until the metal has cooled down and measure the diagonals of the bed frame again.

It remains to make the rear legs of the bed on the frame. We choose the side that turned out to be less even, and weld one strut inside the corners. In this way, we strengthen the corner. We cut off 2 blanks of 250 mm each and weld one in each corner directly to the strut. But if there is no desire to mess with the struts, you can weld pipes to the metal directly in the corner of the frame.

headboard

The following elements are the back at the head and the support stands. The manufacturing process of the headboard is carried out in the same way as in the case of the frame. It is necessary to cut 2 blanks from a professional pipe 800 mm long, and one 1650 mm and 1730 mm each. For welding, we use the same set of tools - 2 clamps and a welding jig.

The only difference from the scheme with the bed frame is that the upper (165 cm) horizontal cross member is welded to the vertical posts in a butt-joint pattern. That is, after welding the metal, a semi-frame in the form of the letter “P” should be obtained.

The lower cross member of the backrest is welded with an overlap (the bed frame will rest on it) at a height of 300 mm from the lower edge of the vertical post. If there is no certainty that the metal is welded with high quality, then the connection can be strengthened with overhead corners 40x40 mm.

Bed assembly

Before further making metal furniture, all parts must be treated with a passivating compound. This is an aqueous solution of phosphoric acid, used in car body repairs to protect metal from rust. The composition is safe and highly effective.

It is necessary to do metal processing before completing the assembly of the bed, so that the entire surface is covered with a protective film. After the details of the frame and back are left in a warm, ventilated room for a day. Then you need to moisten the metal with a clean rag with water. After another day, it will be possible to continue assembling the bed.

In fact, you just need to fix the headboard to its frame. This is not easy to do, since there should be an angle of 90 between the frame and the backO. Otherwise, the bed will look "squeezed".

You have to resort to trickery. Lay the finished bed frame on a horizontal plane (you can use a sheet of plywood on the welding table). The metal will have to be drilled, so we fix the part with a clamp.

On the edge of the frame, lay the back upside down with legs. The part, as it were, hangs on the frame, supported by a cross member. Only in this position between the back and the plane of the frame will there be an angle of 90O. Align the parts, fix them with two clamps.

We will connect the back and bed frame with M12 bolts, 120 mm long. To do this, at the points opposite the places of metal welding, we drill through holes. The drill should go right through the cross member and bed frame.

A wide washer will need to be placed under the bolt head, welded to the frame metal by welding. Bolted fasteners must remain collapsible so that a heavy metal bed can be disassembled, packed, and transferred to the installation site at any time.

The result should be an almost finished bed. So that the back does not look empty, we weld two metal jumpers inside. On the one hand, the furniture design will improve, on the other hand, it will be possible to fix the wooden furniture back. It's better than metal.

Final processing

Most of the furniture has been assembled. What remains is painting and small decorative additions to improve the design of the bed.

The first step is to prime the metal. It is best to use special primers with a high level of adhesion. This coating protects the weld metal well. Therefore, if the bed regularly spends the winter somewhere in the country or in the barn, then you can be sure that rust will not appear.

The next step is painting. Usually the metal is covered with black or light brown enamel, with or without gloss. Definitely 2 layers. If additional decor will not be used, then paint that gives gloss is better. In the event that the head of the bed is complemented by forged patterns, then you need to paint with paintwork materials, giving a matte surface.

Before laying the mattress, the frame must be covered with sheets of plywood or OSB, otherwise the soft part of the furniture can quickly lose its elasticity.

There is another option for finishing, without the use of paint and primer. Frame details are cleaned to a “white metal” shine (photo below).

To do this, you can use nozzles on an electric drill for brushing the metal of car bodies before painting. After machining, the parts are pickled in acid. In this way, you can get a white metal, a shade similar to stainless steel, or make a light patina. After processing, the frame is washed in water, dried with hot air, covered with a colorless varnish.

With the right selection of etching solution, you can get the shine of the shade of "old silver", "copper", "graphite" and even a bluish tint of "hot" metal. The selection of reagents should be performed by a specialist.

How to improve the design of a metal bed

There are several ways to make a bed more attractive and stylish. For example, change the shape of the headboard, backrest.

If possible, it is best to order decorative items made of forged metal. A few overhead details will make the design of the bed more stylish.

It makes no sense to make the entire bed out of wrought iron. It will cost much more, and the structure itself is heavier, not repairable.

The second way is to arrange the backs in a modern style. For example, loft or techno.

The furniture turns out to be stylish, it will easily fit into most interiors of modern apartments. Moreover, you can decorate the bed with additional metal parts both at the stage of its manufacture, and after final assembly and even long-term use of furniture.

Another way to finish is to use wooden shields (homemade). The overlay decor from the boards can be easily fixed on the headboard and at the feet.

To prevent the furniture from looking empty, the side beams of the iron frame are also covered with overhead elements. They will also fix the mattress of the bed from moving along the frame.

Making a metal bed with your own hands is not as difficult as it might seem at first glance. But, as with the assembly of any furniture, the process requires an accurate understanding of the technology, possession of a welding machine, hand tools. In general, with careful marking and welding, the bed will turn out in any case.

Tell us about your experience in building metal home furniture. How difficult was it to choose a project, and whether the result justified the investment and effort. Bookmark this article so you don't lose the assembly instructions.