When planning a scheme for arranging water communications in a house, most problems do not arise with placement of consumers or calculation of water consumption, and with the choice of characteristics and material of pipes for water supply. There are many options, each with its own advantages and disadvantages.

Many nuances of pipe selection are so specific that you can learn about them only from your own experience and after several years of operation.

The content of the article:

-

The nuances of choosing pipes based on the material

- Polypropylene pipes

- Metal-plastic pipes

- Polyethylene pipes (HDPE)

-

What pipe diameter to choose for water supply

- Diameter of polypropylene pipes

- Diameter of metal-plastic pipes

- Diameter of polyethylene pipes

- How to choose polypropylene pipes for water supply

-

Which metal-plastic pipe to choose for water supply

- What to pay attention to

-

Which pipes for water supply are better to choose from polyethylene

- PE 80 SDR 21

- PE 80 SDR 17

- PE 80 SDR 13.6

- PE 100 SDR 26

- PE 100 SDR 21

- PE 100 SDR 17

- PE 100 SDR 11

The nuances of choosing pipes based on the material

Steel water pipelines are gradually becoming obsolete. With rare exceptions, the wiring of water supply pipes is made of plastic or metal-plastic.

It is cheaper in materials and labor, as high-quality steel is expensive. In addition, at least one electric and gas welder will have to be involved, and this is also an expense.

Plastic and metal-plastic water pipelines, in addition to cheapness, have their drawbacks and features. Therefore, when selecting pipes, the following requirements must be taken into account (in descending order of their importance):

- Compliance of the pipe material with the requirements for certain water supply conditions.

- The resistance of the pipe material, the possibility of maintenance and repair of the water supply system at a lower cost.

- The price of pipe blanks, the availability of material in the future to replace (if necessary) individual sections of the water supply system, insert new taps, valves, filters, meters.

- Availability for self-assembly.

Do-it-yourself laying of water supply pipes is a good way to save on the services of a master. But many apartment owners prefer to choose a plumbing scheme on their own in order to be sure of the correct assembly.

Modern technologies for assembling metal-plastic and plastic water supply pipes do not require long-term training in laying methods or complex equipment. It is enough to master the soldering of polypropylene or the installation of fittings, to choose the right tools and devices for installation.

Polypropylene pipes

A feature of polypropylene pipe blanks is their predisposition to soldering (welding). Almost the entire range of polypropylene pipes is cast from a mass melt, consisting of several types of polymers.

Depending on the proportions and additives, the characteristics of the products may vary. But in any case, all brands are perfectly soldered with an electric soldering iron, while providing a strong monolithic seam.

Most apartment owners choose polypropylene only because this type of workpiece is perfectly soldered on their own.

Ordinary PP pipes, depending on the size of the wall, are able to withstand pressure up to 35 bar. All types of PP pipes can be used to assemble home plumbing according to the sanitary and hygienic requirements of SANPiN.

For the manufacture of water supply systems, PPR grades, a random copolymer, are commonly used. You can choose complex reinforced ones - they are more resistant to heat, therefore they are used mainly for heating systems. Pipes made of pure polypropylene are mainly used for supplying drinking water in low-pressure water supply systems.

The only significant drawback of polypropylene water supply systems is that polypropylene has a high coefficient of thermal expansion (0.15 mm / m * K), so the wiring must be done with loops or adapters that compensate for the elongation of pipes when heating.

Metal-plastic pipes

Aluminum-polymer water pipes are a rather complex structure. The metal-plastic pipe itself consists of three layers of different thicknesses:

- The inner layer is low pressure polyethylene.

- The second layer is aluminum foil 0.6-1.1 mm thick. Provides rigidity and strength of the metal-plastic pipe. Withstands pressure up to 16 bar.

- Outer layer made of PE or PEX polyethylene. Protects aluminum from atmospheric oxygen and condensate.

Masters usually offer to choose metal-plastic in cases where water supply needs to be organized in the shortest possible time.

Polymer-aluminum water supply systems have been used for a long time, more than two decades. During this time, a lot of experience has been accumulated in the practical application of metal-plastic pipes.

The durability of the material is high. Metal-plastic of well-known manufacturing companies can be operated for 20-25 years even in hot water conditions. It is often recommended to choose it for wiring a water heating circuit due to its low coefficient of thermal expansion.

But if you choose low-quality metal-plastic pipes, then water supply systems fail in 2-3 years of service.

There are only two disadvantages:

- It is impossible to weld or solder metal-plastic. Docking of water supply or heating pipes is performed only with compression fittings, which increases the cost of the water supply. The type of fitting will need to be selected immediately, depending on the pressure and temperature of the water.

- You will need to buy or rent a special tool - tongs or a sedimentary press.

The main advantage of metal-plastic is the ability to disassemble and assemble the water supply system, change individual pipes, and repair water fittings. It is possible, with the help of adapters, to make a water supply circuit consisting of pipes of different materials.

Polyethylene pipes (HDPE)

The water supply system is more durable and resistant to mechanical stress. Therefore, a polyethylene pipe for water is used mainly in pipelines operating under load.

Pipe blanks made of polyethylene are designed for a lower operating water pressure than in the case of polypropylene. Usually up to 16 bar. At higher loads, 20-25 bar, the pipes may expand or deform in the outer dimension.

The point here is not the strength of the material in tension or bending. Most water systems are assembled by welding. At the same time, polyethylene has a lower weldability (due to the inertness of the material and poor adhesion in the melt).

Therefore, high-capacity water supply systems with a diameter of 50 mm and more are assembled by welding. In home plumbing, assembly is performed using sleeve fittings and a hand press.

The high chemical resistance of HDPE does not mean that any polyethylene pipes can be used for domestic water supply. For drinking water, blanks made in accordance with GOST 18599-2001 are selected.

They are usually blue or black with a blue stripe. Everything that is done in accordance with GOST R50838-2009 is polyethylene pipelines for pumping gas (black color, yellow longitudinal stripe).

The coefficient of thermal expansion of HDPE is about the same as that of polypropylene. Since the rigidity of the PE pipe billet is lower, the pipes can be deformed even at a low temperature of hot water.

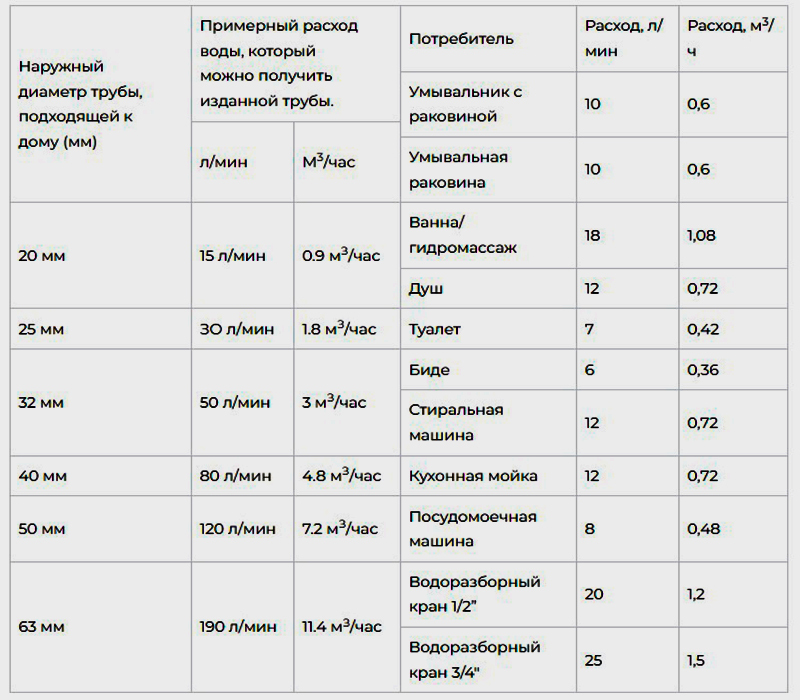

What pipe diameter to choose for water supply

For private households, the internal size of the supply pipe is tied to its length. It is believed that the longer the line, the higher the water pressure loss and the lower the flow rate. For example, for steel water supply lines, such a separation was empirically selected.

For a section up to 10 m, a diameter of 20 mm is sufficient, from 10 m to 30 m - 25 mm. For lengths over 30 m, a line with a diameter of 32 mm is required. According to these recommendations, you can choose polymer blanks for water supply to the territory of a suburban area.

And even reduce by 10%, since the inner surface of the "polymers" and metal-plastic is smooth. Losses will be lower than on steel lines.

The most correct approach is to choose the diameter of a plastic pipe blank, focusing on the maximum water consumption of consumers connected to a given water supply line. It is enough to summarize the outlet section on all connections and select the closest value of the plastic pipe according to the nomenclature.

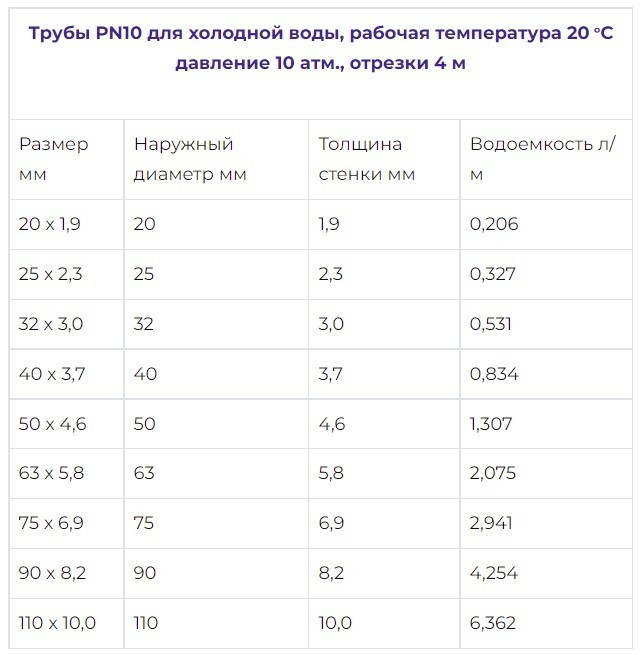

Diameter of polypropylene pipes

Another option is to choose the diameter of the polypropylene water supply line based on the dimensions of the old steel water pipes. Often, during the repair, the owners of the apartment take measurements from the old water supply and transfer the diameters to the new pipes. The approach is correct if the old water supply system met the needs of the residents.

But there are two important things to keep in mind:

- The pressure in the water supply pipes must not change. If the riser and the central water supply valve were replaced with the old water supply in the apartment, then the result of calculating the cross section will turn out to be overestimated.

- It will be necessary to choose a new diameter of the water supply pipe, taking into account changes in the inlet water pressure. For example, if the old riser had 2.5 bar, and after replacing it with a new one it turned out 3 bar, then you can choose a workpiece with a cross section of 15% less.

Another nuance - the systems for measuring the diameter of a steel pipe and a polypropylene one have differences. Steel blanks are produced in a standard range of diameters.

For domestic water supply systems, these are 15 mm, 20 mm, 25 and 32 mm. In inches, respectively ½”, ¾”, 1” and 11/4”. In this case, we are talking about the inner diameter.

For polypropylene pipes, the measurement is performed on the outer diameter. In the marking, the wall thickness is added to the size.

To recalculate you will need:

- Measure the diameter of old steel water pipes.

- Determine the standard internal size from the range of nomenclature.

- Select from the table a polypropylene blank with a recalculated internal dimension (subtract double the wall thickness).

Calculations may not match. In this case, experts recommend taking a PP pipe from the row with the nearest diameter value, provided that the size reduction is no more than 10%.

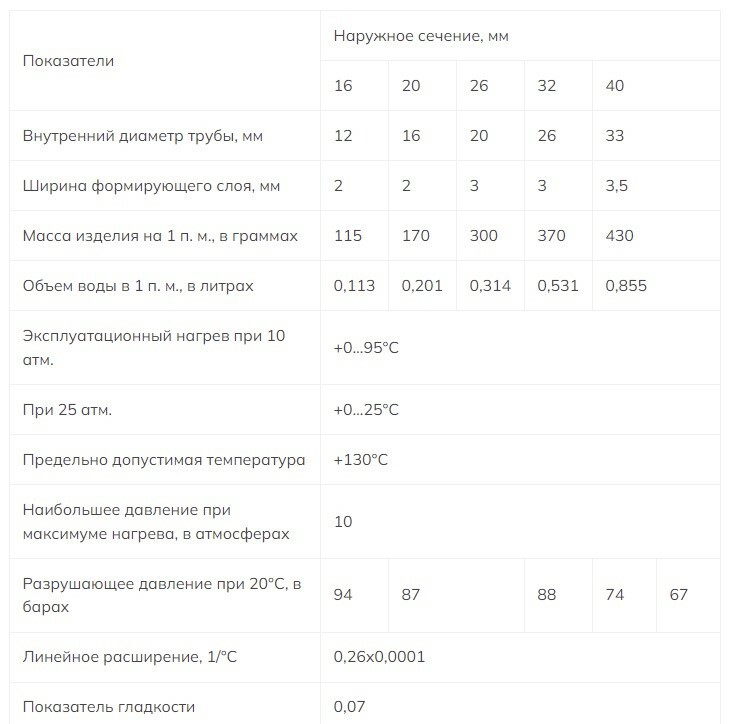

Diameter of metal-plastic pipes

The performance characteristics of metal-plastic are higher than those of polypropylene or polyethylene. For example, the magnitude of the breaking pressure at room temperature. For a metal-plastic water pipe with a transverse dimension of 16-26 mm, it reaches 90 bar - much more than in the case of plastic water pipes.

This means that with proper assembly and high water quality, metal-plastic should last longer than PP or PE. Manufacturing companies claim a period of 50 years, although in reality the water supply system will last no more than 30.

The use of metal-plastic water pipes has one important advantage. The core of the tube billet - aluminum is not subject to structural changes over time, under the influence of water or temperature.

The aluminum part will ensure the strength and bearing capacity of the water supply system even after 100 years (if there is no contact with water). In polyethylene and polypropylene, the material ages due to the residual effect of catalysts remaining in the polymer mass. Therefore, the service life for PP pipes and HDPE pipes will in any case be lower.

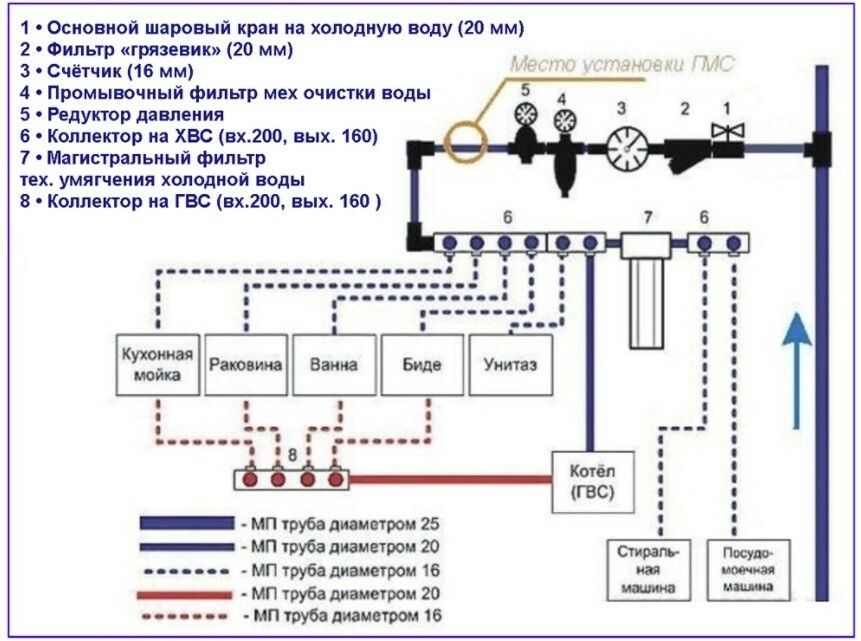

The diameter of pipe blanks can be selected, guided by a typical wiring diagram for a metal-plastic water pipe.

For private houses and apartments, owners usually choose a collector wiring diagram.

Diameter of polyethylene pipes

Polyethylene-based water supply systems are becoming more and more popular, PE pipes are gradually being squeezed out of the market. Apartment owners try to choose HDPE pipes and install polyethylene water pipes for 3 reasons:

- The reputation of low pressure PE pipes as the safest for drinking water in terms of hygiene standards.

- Simplification of the technology of welding-joining polyethylene blanks.

- Polyethylene of the HDPE brand is distinguished by the fact that there are practically no deposits of rust, silt, and debris on the inner surface of the water pipe. This means that you can immediately select a workpiece of the desired diameter, without correction for silting of the passage section at the places of welding or soldering of the joint.

For polyethylene water supply systems, the required diameters can be selected based on the total and individual water consumption of each consumer.

How to choose polypropylene pipes for water supply

In the building materials market, you can find a huge amount of imported and domestic PP water pipes. Pipe polypropylene from the Italian company Valtec is considered the best.

Slightly cheaper, but good quality PP-pipes of the Czech company "FV-Plast" (trademark "FAZER"), Turkish "Kadle". For lovers of German building materials, you can recommend the brands "Watertec", "Climatec".

To enter the house from the pump to the accumulator, it is better to choose pipe blanks with a diameter of at least 32 mm. But the water supply system will work properly even if you choose 24 mm.

But only the first 5-7 years. Further, as silt is deposited on the welded joints, the throughput will decrease, so it is better to take the workpiece with a margin.

To enter the apartment, you can choose 24 mm - the water in the city network is purified from organic matter, so there will be no acidification of the water supply.

Usually, for domestic water supply systems, experts recommend choosing PP-pipes of the PPR brand. For the distribution of water supply inside the house, pipe blanks of class PN10 are sufficient, designed for operating pressures up to 10 bar. For areas of water supply with increased pressure, for example, from the pump in the well to the top filter, it is better to choose a PP pipe with a class of PN30.

Another nuance - the durability of polypropylene water pipes depends on the temperature of the water. For hot water supply, it is recommended to choose reinforced products based on a heat-stabilized PP-RCT polypropylene matrix and fiberglass.

Which metal-plastic pipe to choose for water supply

It is more difficult to choose metal-plastic for water lines, since the quality of the workpiece largely depends on the quality of welding of the aluminum sublayer. It is impossible to see the seam, but you can try to evaluate it by the cut of the workpiece, but this is also a rather risky way. The only option is to choose a metal-plastic pipe of a well-known brand, for example, the Italian "Valtec" or the German "Oventrop".

Communications from a metal-plastic pipe with a diameter of 26-32 are most often used to enter a house or for the central riser of high-rise buildings. Sometimes it makes sense to choose blanks of 26 mm in a situation where the inlet pressure is low, 1-1.2 bar, or for wiring channels according to a warm floor scheme.

26 mm is enough to enter the house. If you make water supply inside the housing according to the collector scheme, then for each of the consumers it is enough to supply a line of 16 mm for a faucet on a bathtub or a washing machine.

For the rest of the wiring, you can choose communications of 12 mm. This is more than enough for normal water supply even at maximum load.

Up to 70 liters of water passes through such a section per minute, and the flow is limited only by taps and valves. If the pressure in the water supply system is at least 3 bar, and the diameter of 26 mm is selected for the inlet, then at any tap the water flow will be at least 12 l / min.

What to pay attention to

The desire to choose a pipe material of a larger diameter with thick walls is understandable - plastic and aluminum, although they look modern, are somehow not particularly reliable. No one wants to put clamps on a fistula or an accidentally damaged wall.

But experts advise choosing pipes with a diameter of no more than 20 mm. The reason is that metal-plastic communications will have to be bent at turns or when connecting to the consumer.

This will require a lot of physical effort. In addition, for MP pipes there are restrictions on the minimum arc radius.

The larger the diameter, the smoother the bend should be. This is important, especially when the water supply system is planned to be laid in boxes under plaster.

The purchase of large diameter pipe blanks for plumbing means the need to choose more expensive fittings. Moreover, on the hot water supply system at the joints, it will be necessary to periodically, once every 4-5 years, compress the fitting to compensate for the collapse of the gasket.

Which pipes for water supply are better to choose from polyethylene

Often the question arises about the advisability of using polyethylene communications, if you choose metal-plastic and polypropylene that have been repeatedly tested in practice. Polyethylene better tolerates mechanical stress, lateral pressure, bending, twisting, freezing. Therefore, it makes sense to choose polyethylene communications for laying water supply systems in difficult conditions.

For water supply, pipes made of polyethylene of two grades are used - PE80 and PE100. The properties are almost the same, except that the first is less tensile, the second is able to withstand large bursting stresses at elevated pressure.

Choose a pipe for water supply taking into account the dimensions and design pressure. Therefore, in addition to the grade of polyethylene, the SDR index is used. This is the ratio of diameter to wall thickness, the index helps to choose a pipe for strength and maximum (working) pressure.

PE 80 SDR 21

This type of pipe billet is used for arranging cold water supply communications. Index SDR=21 is quite large, which means that the wall is relatively thin.

The pipe is weak withstand pressure no more than 8 bar. You can choose for underground water supply, provided that communications are laid on a prepared pillow. The polyethylene temperature should not exceed 40℃.

Suitable for non-pressure sewerage of residential premises. The minimum diameter of PE 80 SDR 21 is 40x2 mm. The average price per linear meter is 54-55 rubles. You can choose to equip a section of the water supply from the adapter to the input to a one-story house.

PE 80 SDR 17

Working pressure - 10 bar. It is used for communications for drinking water indoors or laying in the ground to a depth greater than the level of soil freezing. Can be selected for laying irrigation systems. Since the pipe is made of PE80, that is, the heating limit is no more than 40 ℃.

The minimum size is 32x2 mm. The average price is 42 rubles/m. P.

PE 80 SDR 13.6

Designed for a working pressure of 10 bar. You can choose to equip water supply inside a residential building or cottage. It is often used for laying temporary communications for pumping water from pools, ponds, stocks in tanks for watering plants.

The minimum size is 25x2 mm. The average price per linear meter is 32 rubles.

PE 100 SDR 26

Despite the high SDR, this type of pipe is highly durable. Thin walls are able to withstand pressure up to 6.3 bar. And only due to the fact that polyethylene-"weaving" has a greater density and rigidity.

PE 100 SDR 26 is used to produce low-pressure and high-capacity water pipes. You can choose for sewerage in a bathhouse, summer kitchen or country house. The minimum size is 50x2 mm. The average cost is 65 rubles / m.p.

PE 100 SDR 21

This type of tubular blank can withstand pressure up to 8 bar. It somewhat loses to the brands PE 80 SDR 17 and PE 80 SDR 13.6 in terms of bursting load, but, unlike competitors, it has greater stability. Can be selected for water supply systems that are constantly under load.

The minimum diameter is 40x2 mm. The average price is 52 rubles/m. P.

PE 100 SDR 17

Pipes of this brand can be chosen for wiring the main lines of the water supply system in a house or apartment. Plumbing made of PE 100 SDR 17 is more reliable than when using PE 100 SDR 21.

The maximum pressure is 10 bar. The average price per linear meter is 42 rubles.

PE 100 SDR 11

Tubular blanks of increased strength are usually used for main water pipes with a pressure of 16 bar. You can choose to connect a pump in a well or supply water to a house at a considerable distance from the water source and with a large elevation difference in the terrain.

This brand of pipe is popular among apartment owners due to its low cost, simple soldering technology. The minimum diameter is 20x2 mm, the average price per m.p. - 26 rubles.

To choose the right pipes for water supply, you need to know exactly the characteristics of the future water supply, the flow rate and pressure of the water. And also take into account the associated costs for the purchase of tools, fittings and consumables.

Share your opinion - what type of pipes is best for arranging water supply with your own hands? What is the advantage of such a solution, and what problems can arise? Save the material in your bookmarks so as not to lose it.