On any, even the simplest summer cottage, there should be a barn in which you can store equipment, water, and plant food. It is from him that the beautification of the territory begins, and often even the construction of a house. It is best to build a wooden shed with your own hands. The design is simple, there is enough material, and almost everyone knows how to work with boards and timber.

The content of the article:

-

Advantages and disadvantages of a shed roof

- Possible problems

-

Preparation for construction: drawings and dimensions

- materials

- Tools

-

Step-by-step instructions for building a frame shed with a pitched roof

- markup

- Foundation

- Strapping lower from a bar

- frame

- Building floors and walls

- We warm the floor

- We insulate the walls

- Roof

Advantages and disadvantages of a shed roof

You can build a temporary hut from timber, boards, steel profiled pipes. You can just buy a ready-made watch or a plastic Chinese box for storing tools. Many homeowners do just that.

But, as practice shows, the best solution is still a frame shed with a simple pitched roof.

Advantages of a frame structure made of timber:

- The construction of a frame-type barn from a bar will cost about half as much as the variant with a log house, and about three times cheaper if brick or cinder block walls are placed under a pitched roof.

- It is possible to warm the room well with modern heat-insulating materials. As a result, the weight of the barn structure will turn out to be small, which means that there is no need to build a shallow foundation.

- The use of wood guarantees minimal heat loss, and in the heat it will be quite cool in the barn.

- A shed roof is quite simple in design, even a beginner with little experience in building wooden structures can make it.

Another plus, which few people pay attention to. For example, a wooden shed with a gable roof is considered "cold". Roof overhangs on the northwest side cover the upper parts of the walls from the sun's rays. Therefore, the tree will need to be regularly processed, protected from water and condensation, otherwise the material will rot.

A barn with a shed roof usually has no problems with wood. It is enough to correctly orient the building on the ground, facing northwest. The lower overhang of a shed roof will warm up well with solar heat, and the upper one is always open, therefore it is blown through with a draft.

In addition, many summer residents choose the option of a shed from a bar as the simplest option, hoping to disassemble it for building materials after the construction of a capital house is completed.

Possible problems

The design with a shed roof has a high windage. Simply put, a building with a flat roof with a slight slope is less resistant to gusts of wind. If the summer cottage is located in an open field, then it is possible that a hipped roof is better suited for a barn.

At the same time, in order to hide a shed with a shed roof, it is enough that several mature trees grow on the border of the site, or a neighbor has already built a house.

The problem of windage means that the barn will not be able to use the usual columnar foundation, which is widely used for most timber frame structures. Piles will need to be installed.

Preparation for construction: drawings and dimensions

First of all, you need to find a suitable project. Convenient enough, but simple. It is advisable to make drawings. Frame structures with a shed roof can be quite complex, as in the photo, so you need to choose what you can build with your own hands.

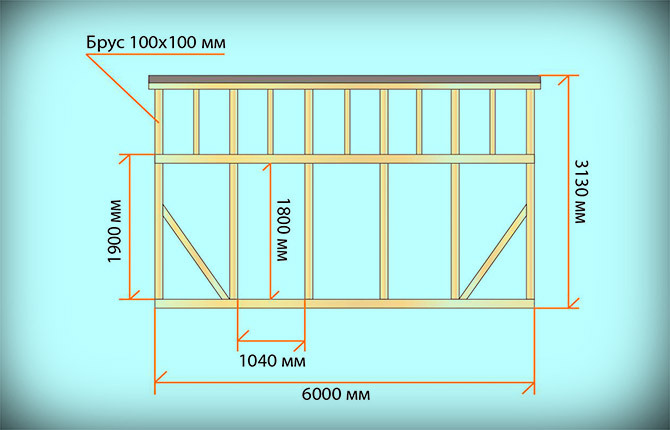

The optimal size for a simple barn is 3x6 m or 3x5 m, depending on the required usable volume of the room.

A shed wood frame shed cannot be placed directly on the ground. The foundation option in the form of a slab or MZF is not suitable. The tree at the base of the building will rot even on dry ground. Therefore, the barn box will need to be placed on piles and raised above the surface by at least 30 cm.

materials

The frame, racks, lower and upper strapping will be made of a 100x100 mm beam, an inch board, rafters - from a 50x100 mm beam, logs under the floorboards will also be typed from it. Most of the connections are made with nails. In addition to the lower trim, threaded studs, self-tapping screws, and steel corners are used in this area.

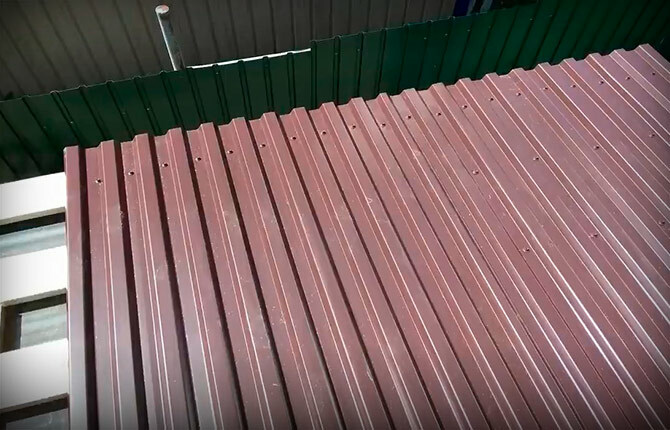

The corners of the box are sewn up with a plastic corner, and the overhangs are hemmed with a cornice (frontal) bar. A corrugated board will be used as a shed roof.

Walls and floor will be insulated with slabs mineral wool TechnoNIKOL.

External wall cladding can be made of wood (lining), plastic siding or sheathed with panels.

In addition, a small window will be embedded next to the door. There is no electricity and lighting inside the barn, so at least a weak illumination is needed for orientation in space. If desired, the window can be made like a transom, then the wooden frame shed can be ventilated, for example, in extreme heat or rain.

Tools

For preparation, you will need a garden drill 180-200 mm, a wheelbarrow for removing soil, a container for mixing the solution, a shovel.

At the stage of construction of the strapping - hacksaw for metal, grinder, circular saw, laser level, screwdriver.

When assembling the frame, you will additionally need a building level, a hammer, a stapler, a wood saw.

Interesting: Do-it-yourself gazebo with a pitched roof

Step-by-step instructions for building a frame shed with a pitched roof

The process of building a hozblok can be conditionally divided into 4 stages:

- Preparation of the site, foundation, arrangement of the lower harness.

- Installation of vertical racks, assembly of the upper trim and frame of a pitched roof.

- Wall and floor insulation.

- Laying roofing on a shed roof.

You can detail the process in the form of step-by-step instructions, but this method is used only for custom construction. The advantage of this project is that it can be implemented by anyone who has done even a little carpentry. The most difficult stage is the insulation and laying of the roof on a pitched roof, in which case you can invite an assistant.

For the construction of a shed shed, a site was chosen next to the neighbor's fence. According to the plan, the barn will stand with its back to the fence. Here is the neighbor's house. The slope of the shed roof is oriented towards the fence. It turns out that the shed shed is well protected from strong gusts of wind.

markup

The area under the barn is quite flat, without a sharp slope to one side. Therefore, for preparation, you just need to remove tall grass and debris. Marking is carried out using four pegs hammered into the ground at the corners. At the same time, the distance along the diagonals of the rectangle is controlled.

According to the instructions for a shed shed, at least 12 pile supports are required. All elements of the building, with the exception of the roof and external cladding, are made of wood, the total weight barn - no more than 500 kg, so small piles of 150 mm in diameter, depth of 100-120 will be enough cm.

Points for drilling piles should be marked with a tape measure along stretched cords. We mark the length on the cord with a marker and use a plumb line to find a point on the ground. Holes for piles are drilled with a garden drill 170 mm in diameter. Depth - 110 mm.

Foundation

Now you need to install the formwork under the piles and pour them with concrete. As a formwork, you can use asbestos-cement pipes. The method is reliable, but, as practice shows, it is more convenient to put pieces of vinyl (orange) sewer pipes with a diameter of 150 mm for external sewage.

Formwork manufacturing scheme:

- Cut into 12 blanks 130 cm long.

- Circles of 155 mm in diameter (12 pieces) are cut out of the roofing material, fixed to the bottom of each pipe with adhesive tape.

- Each blank is wrapped in a bag of thick polyethylene film and lowered into a drilled pit. First, you will need to shower a small amount of sand inside and tamp it so that the bottom of the pit is flat.

Align vertically and fill the sinuses between the pipe wall and the soil with a mixture of sand and gravel.

Now the most important stage. Before pouring concrete, all 12 pipes must be cut so that their ends are located in the same horizontal plane at a height of 12-18 cm. It is quite difficult to do this by eye or with the help of cords; a high height error is obtained. Therefore, it is better to rent a laser level for one day and use it to mark the cut line on all 12 racks. You can cut it with a regular hand saw for metal.

For pouring, a standard cement-sand mortar with the addition of fine gravel is used. As soon as the pipe is filled with concrete, threaded studs with two screwed nuts on the lower end are immersed in the solution. This will be an anchor, so the thread should protrude at least 120 mm above the concrete.

After pouring, you will need to wait a period of at least 5 days.

Useful: How to attach a comfortable terrace to the house with your own hands

Strapping lower from a bar

Next, you need to make a strapping of piles of wood. The base of the shed is quite large. Ideally, the strapping should be done with solid wood blanks, only then can the required rigidity of the frame be achieved.

Therefore, if it is possible to buy at least three pieces of wood 6 m each and two 3 m each, then you need to buy. To collect the strapping, it will be enough to make gashes at the ends of the beam in half a tree and plant the parts from the beam on the studs.

If there is no other option, then you will have to assemble the strapping from 1.5-2 m pieces of wood. In this case, each hole drilling point under the hairpin will have to be marked separately, and two mating parts made of wood should sit on the hairpin without a gap and without a strong tension.

To make a half-tree castle, you need:

- Mark 110 mm from the end of the timber and cut with a hand saw to a depth of 50 mm.

- Parallel to the first cut, another 4-5 cuts are made to the same depth.

- The tree is chopped off with an ax and a hammer, and the resulting area is cleaned, if necessary, cut with a chisel to fit the plane.

One more nuance. A long piece of wood cannot be precisely drilled and laid on studs. Therefore, first of all, holes are drilled at opposite ends of the timber, then they are placed on the ends of the studs and several light blows are applied. Prints (dents) remain on the tree, according to which markings are made and holes are drilled.

After all the details of the wooden strapping have been marked and cut, an undercut for the nut is made in the holes, the beams are marked and removed. Next, screw the nuts onto the studs, cut off the excess thread. The height of the stud should be such that the nut is completely recessed into the wood of the beam.

Since the floor is supposed to be insulated, the entire tree of the lower trim of the barn must be treated with a mixture of white spirit, then covered with roofing mastic. Otherwise, the tree will rot.

frame

The next step is to install vertical wooden racks. For the front and rear walls, you will need to set up 8 vertical supports from a 100x100 mm timber (including corner ones). On the lateral projection, there are two more racks on each side.

Four corner supports are installed first. Each is aligned vertically with the help of a building level, applied to the tree along two edges of the beam. As soon as the stand takes the correct position, it is fixed with two struts made of slab or scraps of wood. The process is long and tedious, it takes at least 20 minutes for each wooden stand.

Now you need to install the internal supports. To speed up the process, you need to pull two cords between the corner posts, one along the side edge, the second but the heads.

Now you can put vertical racks, controlling only that they are in the same plane of the barn facade. Immediately sew longitudinal struts and install additional struts. This is necessary so that the front wall of the shed does not deform when laying the upper trim under a pitched roof.

Vertical racks are reinforced at the bottom with steel corners.

Building floors and walls

On the facade, the vertical posts are 60 cm higher than the overall height of the shed frame. In fact, this is the front part of the shed roof of the barn, so the first beam of the upper trim is placed on the highest racks. So far, the crossbar is temporarily attached to the supports with the help of self-tapping screws screwed “on an oblique” into the tree.

At this stage, it is important to align the beam horizontally so that the pitched roof looks flat. After leveling, using a level, the back and side sections are fixed in a similar way.

The next step is to make the floor, it will be plank, insulated with mineral fiber boards. Lag beams (8 pieces) are cut from blanks 50x100 mm and laid on the bottom trim “on the end”. Each lag is fastened with self-tapping screws into the tree to the vertical posts of the barn.

In the gap between the two racks, where the box with the door will be installed, an additional tree is sewn onto the strapping. This will be the threshold and at the same time strengthening the frame.

The walls of the barn along the outer plane are sheathed with boards. The tree will need to be treated with bioprotection agents and dried thoroughly. All temporary struts and struts must be removed before installing the insulation of the barn.

We warm the floor

For laying insulation, you need to assemble a subfloor. It can be stuffed from boards, edged boards, lining, any waste wood, as is done when insulating the ceiling of a country house. Faster and easier to hem the logs with OSB sheets.

Since the distance between the lags is different, the blanks for the subfloor are cut out of the plates individually in size. The floor area of a shed shed is large, so you should not try to hem the logs of the shed with large pieces of OSB, this is inconvenient. The recommended size is 1x1 m. A handle is sewn into the center, and several wooden bars around the perimeter. With one hand they hold the slab, with the other they wrap the screws into the wood of the log beams on an oblique. You can sew up boards with scraps, any tree will do, as long as it is dry.

The next step is to lay the insulation of the barn floor. Pieces of TechnoNIKOL plates are cut, the width of each should be 1-2 cm less than the distance between the lags. When laying, the insulation must be pressed tightly against the adjacent edge and against the tree of the log beams so that there are no cold bridges. Next, a vapor barrier membrane is laid on top, fixed with a stapler with staples directly to the log tree.

A rail 20x50 mm is sewn on top. It is for fixing the film. In addition, the installation of “counter-lattice” rails provides an air gap between the insulation and the wood of the floorboards. And this is important for floor ventilation, since a shed shed will not be heated.

The last step is the padding of the floorboards. Unlike conventional plank flooring, self-tapping screws are used rather than nails. Otherwise, you can split the slats, and the floor of the shed barn will have to be changed in a couple of months. If there is no other option, and you need to beat nails, then you will have to drill a hole each time before driving the fasteners. In addition, each nail is dipped in liquid soap.

In this way, plank floors, oak and larch logs are collected. It is clear that hardly anyone will use such expensive building materials for the construction of a shed. Often these types of wood are used for the lower strapping of the shed if the soil is waterlogged by groundwater.

We insulate the walls

The process of thermal insulation of the frame of a shed shed is almost the same as in the case of a dwelling. Initially, a vertical crate made of wood 40x40 mm is stuffed on the outside, in increments of 50-150 mm. Reiki will also need to be pre-treated with a mordant from pathogenic microflora.

Thermal insulation is laid in the gaps between the vertical posts. It is recommended to cut one solid mineral wool mat for each niche. In this case, there will definitely be no drawdown of insulation, the appearance of cracks and cold bridges.

From the inside of the shed, a vapor barrier membrane must be sewn on top of the insulation. From the outside, this can not be done, since the shed has no heating. And a small amount of water vapor released during the breathing of people or the storage of crops is easily removed through the vents of a pitched roof.

Immediately after laying, you need to sew up the walls of the shed shed with cladding. It is important to close the thermal insulation and the wood of the walls with panels without delay, as dew, condensation or even a little rain can damage the insulation.

Be sure to make steps at the entrance to the barn. Moreover, it is best not to lay out a couple of cinder blocks, but to put at least a couple of treads on the stringers.

Roof

The design of the shed roof of the barn is simple. Initially, you need to select 10 pieces of timber 4 m long, the most even and high quality. One timber will go to the manufacture of a pitched roof template. It is laid on the beams of the upper trim and washed down with squares. It is clear that you will have to try on and clarify the slope of the pitched roof a couple of times.

All truss beams are cut according to the template, they are lifted to the barn and nailed. If there are no problems with leveling the shed roof frame, then the rafters are reinforced at the attachment points with steel corners.

Next, you will need to lay a film waterproofing directly along the rafters. The film is fixed with staples (with a stapler in the rafter tree), then with longitudinal slats 20x40 mm.

Now you need to sew a counter-lattice board, a tree of 100x20 mm is used. The material is fastened in a through way to the beams of the rafter beams with self-tapping screws.

The last stage is laying sheets of corrugated board on a shed base. It is also fixed with special self-tapping screws with a silicone gasket. Usually after three waves to the bottom of the fourth. After laying the roof of a shed shed, it is imperative to hem the cornices from the front side, and install at least a couple of gutters from the back. Otherwise, the tree under the overhang will get very wet.

Building a barn with a shed roof is a creative process. In the course of use, you always have to add or redo something. Therefore, the remnants of materials and some tools are often stored in a shed so that you can cut a tree, finish something off or strengthen a pitched roof.

Read: How to make a barn from a profile with your own hands

Tell us about your experience in building wooden sheds - is it worth choosing a shed scheme for a summer cottage?