A drill circular is a convenient device that you can actually make yourself from improvised materials. The design is made on the basis of MDF panels and wooden beams, as well as door hinges and various elements for fasteners. Step-by-step instructions for making with a photo and a description of the actions are presented in this article.

The content of the article

- Materials and tools

- Step-by-step instruction

Materials and tools

A circular saw from a drill is made using standard materials and tools that can be found in any garage or workshop. To do this, you need to prepare the following tools:

- wooden beam;

- half collar made of steel;

- plate based on MDF;

- clamp;

- fastener - a set of screws, nuts with bolts;

- the saw blade itself (purchased separately);

- mortise door hinges;

- hammer with an awl;

- profile type washers;

- drill;

- wrenches of different numbers;

- construction roulette;

- jigsaw;

- pencil.

Do-it-yourself circular saw from a drill is made in different ways. So, you can purchase a device, as in the photo. A drill is placed on it, fixed with screws, and then attached to a pre-made wooden base.

Step-by-step instruction

You can make the device yourself, which will significantly reduce the cost of it. The main way to make a circular from a drill with your own hands consists of the following steps:

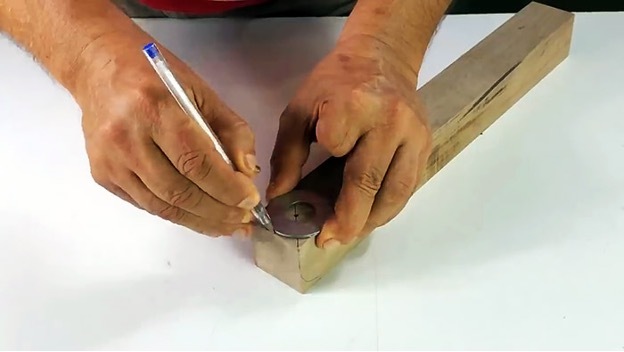

- Mark the beam from one end. You need to mark the places for drilling, as well as circle the washer to round the corners. Mark a point in the center of each end - there will be a blind hole.

- To get a high-quality circular from a drill with your own hands, they take a Forstner drill and make several identical recesses in the middle part of the timber on one and the other (opposite) side.

- From one end, make a hole in the form of an axis that will run parallel to the drilling axis. Round corners. At the opposite end, make a blind hole in the form of an axis.

- Bearings are installed in the central recess, knocked out with a hammer directly through the bar. This is necessary so that the saw from the drill is durable and reliable.

- Construction tape is wound on the hairpin, making 2 turns. They should go symmetrically about the center.

- Next, a do-it-yourself saw from a drill is made like this. Washers with nuts are screwed onto the studs and tightly tightened with wrenches. To make the design stable, expose the second lock nuts.

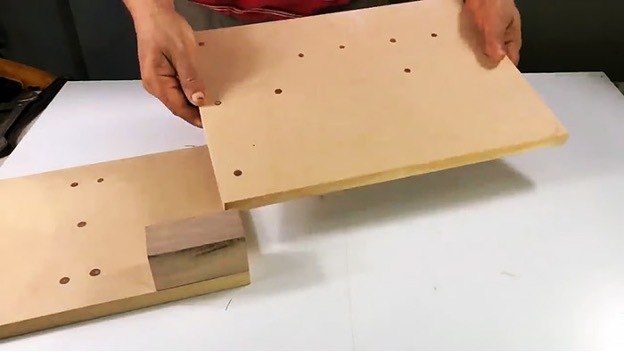

- They take a small fragment of a beam with a square section, drill a hole (blind) along the axis in the center of the end.

- The described method, how to make a saw out of a drill, involves making a square from an MDF panel. The piece of timber obtained at the previous stage is placed at any angle of this panel and fixed with screws. In this case, the bar must be installed so that the hole "looks" inward.

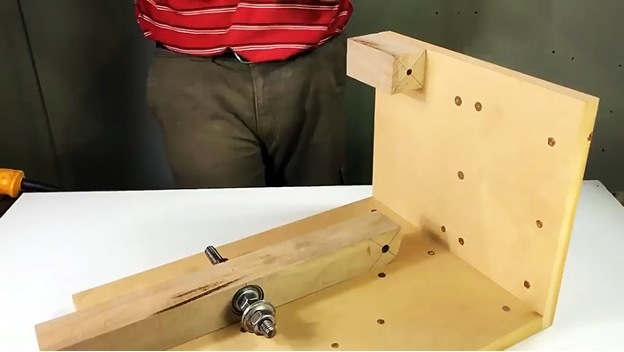

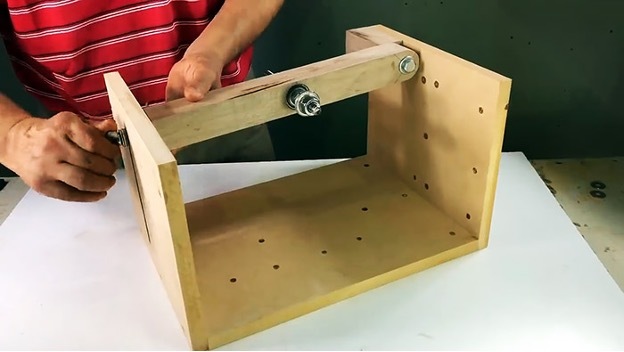

- The MDF square is set vertically so that the bar is at the top. And a rectangular fragment of the same MDF material is attached to the bottom. One of its sides must be equal to the side of the square. Both fragments are fixed with screws. The installed beam with a stud is mounted with a short beam using a washer and a bolt.

- The result should be something like this.

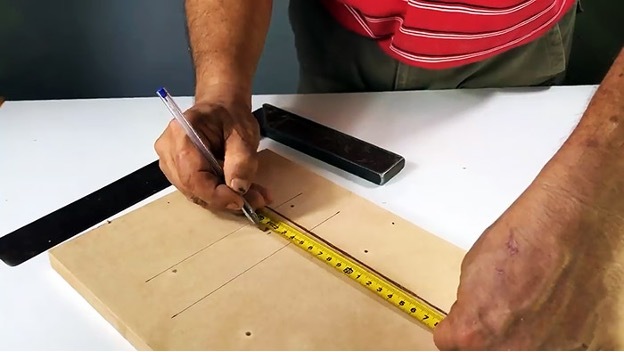

- The next step in the instructions on how to make a saw out of a drill is to get another square blank from MDF. A vertical groove is marked on it. In this case, the axis that goes longitudinally must coincide with the central hole that goes on the end of the bar.

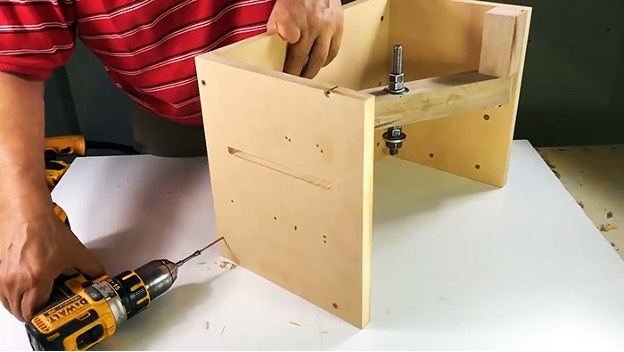

- Holes are drilled in this square and cutouts are made using an electric jigsaw, as shown in the photo.

- In order for the circular saw for the drill to be stable, the square, together with the groove, is connected to the end of the rectangular base using screws.

- Next, in the groove you need to fix the pin from the outside. It is pre-bent at a right angle. This stud should have a pointed end and a wing nut. It is screwed into the prepared hole on the end of the beam.

- A rectangular MDF console is fixed symmetrically with respect to the center of the wooden block. She is directed towards a small wooden block. They are fixed with bolts having spikes, as well as several heads in the shape of a semicircle.

- It remains a few steps - and the do-it-yourself circular from a hand drill will be ready to go. The drill chuck is fixed at the very end of the stud. Next, they take a half-collar and wrap it around with a belt on the body of the drill itself. They are fixed with feints, and tightened with nuts from the bottom side.

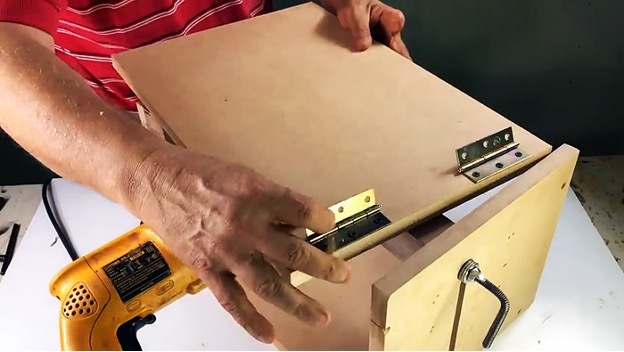

- Now you need to ensure the strength of the structure so that the mini-circular from the drill works reliably. To do this, a rectangular piece of MDF is laid on top and fixed from the outside to a rack with a beam. To do this, use ordinary hinges for doors that cut into the surface.

- Fold back the rectangular part and mount the disk of the future saw using profile washers.

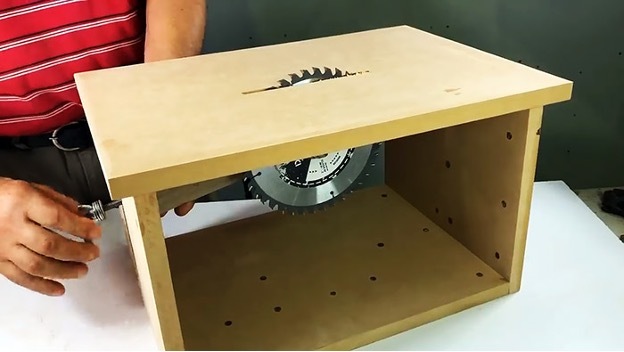

- Do-it-yourself mini-circular from a drill is almost ready. You just need to turn on the drill and slowly lower the flipped panel, turning around the hinges. If everything is done correctly, the disk should cut through the groove, which forms the working surface. Next, you need to slightly loosen the lamb and move the pin in the form of the letter “g”, setting the required depth of cut.

A device for turning a drill into a circular saw can be obtained at home. The main materials are MDF and wooden beams. It is recommended to draw up a diagram in advance and designate all attachment points. Then they assemble the structure step by step, make a test cut and get to work.