A minitractor is an indispensable thing when you have your own land and a small farm. If the mini tractor does not have attachments, then it turns into a pile of ownerless scrap metal, since it will not be possible to perform any household manipulations on it.

Attachments for mini tractors can be modeled with your own hands if it is not possible to purchase factory products. For this you need to have:

- the necessary material - there should be no problems with it, because now you can buy anything;

- a tool so that you can cut, drill and weld a metal structure - there should be no problems with such a tool in subsidiary farms either;

- wish;

- metalworking skills.

The content of the article

- Attachments for mini tractors: features

-

Do-it-yourself attachments for mini tractors: manufacturing

- KUHN on a mini tractor with your own hands

- Conclusion

Attachments for mini tractors: features

With independent modeling of attachments, a three-point hitch on a minitractor is most often used, so how it ensures high-quality fixation of equipment and maneuverability of the minitractor at the time of execution works.

Homemade attachments must meet the following requirements:

- made of durable metals;

- modeled for specific work;

- match the power of the mini tractor.

It is important to make homemade products from good materials and perform high-quality welding work so that the equipment does not break in the process. Therefore, there is no need to rush to equip the mini tractor with attachments, but to do everything with high quality.

A minitractor is an average between a walk-behind tractor and a full-fledged tractor, so you don’t need much rely on its capabilities and hook or manufacture attachments, as for a full-fledged tractor. It is important to remember this at the design stages of homemade attachments so as not to design too large a bucket, plow, cultivator, etc. If the minitractor constantly works under high loads, then there is a risk that it will fail very quickly.

The main feature of home-made attachments for a mini tractor is a relatively low cost. In most cases, manufacturing a product is cheaper than buying a factory counterpart. Plus, self-production allows you to take into account the technical features of your own mini tractor.

Do-it-yourself attachments for mini tractors: manufacturing

Among independently manufactured attachments, it is possible to meet various products:

- plow for plowing the estate;

- harrows for tillage after plowing;

- a cultivator for loosening the estate and the destruction of harmful plants between the rows of plantings;

- sprayer for processing plants;

- towing device and trailer for transporting goods;

- snow blowers, scythes, cutters, knives, etc.

In general, the modeling of attachments is limited only by the imagination of the owner of the minitractor.

Today in the article we will not analyze all types of possible attachments, but we will talk about one thing - about KUNs.

KUHN on a mini tractor with your own hands

KUN is a universal mounted bucket. KUHN belongs to the equipment category for front loaders. KUN is needed when it is necessary to transport or transfer bulk materials, for example, grain in warehouses or sand with crushed stone at construction sites.

The factory KUHN looks something like this:

To make KUHN for a mini tractor with your own hands, you need: In handicraft production, KUHN does not look so impressive, but this does not diminish its functionality.

- Consider fasteners on the minitractor itself. Each mini tractor has its own specific design features, so there is no general recommendation. The main thing to understand is that the fastening of the KUN structure must be reliable, therefore, if necessary, it is possible to strengthen the frame of the minitractor with an additional metal corner, a square pipe, etc.

- KUHN itself can be made from metal sheets 3-6 mm thick. The choice of sheet thickness and bucket size must match the capabilities of the minitractor. That is, the more powerful the minitractor, the larger the bucket can be. It is not necessary to make KUHN from a single sheet of metal, you can make them in small pieces.

- Consider a hydraulic system. The hydraulic booster must match the size of the KUHN and the power of the tractor.

A bucket welded from improvised pieces of metal may look like this:

This is a large bucket for a large mini tractor. In your case, the bucket may be much smaller.

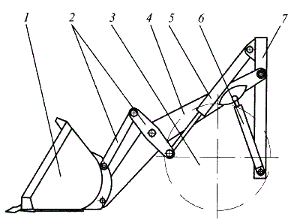

In the factory interpretation, the KUHN design looks like this:

Where:

- Ladle

- secondary levers.

- Center of gravity and position of the front wheels of the minitractor.

- Main lever.

- Hydraulic lift.

- Hydraulic lift.

- The mechanism of attachment to the minitractor.

No one is forcing you to do exactly the same as the factory design. For example, some craftsmen have thought of their own system for KUHN, which looks like this:

For small tractors, you can also make KUN with your own hands. The KUHN itself will also turn out to be small in size and will look like this:

Note that mounting KUHN on small mini tractors does not always follow the recommendations. That is, the factory mount assumes that it will be located closer to the middle of the tractor and thus the center of gravity will not be located on the front wheels of the tractor. However, with self-installation of the mount, it is not always possible to achieve such a result. This is not a big problem if the mini tractor is small and will not work with heavy loads. Therefore, many do-it-yourselfers attach the KUHN in front of the minitractor and it turns out something like this:

Conclusion

Do-it-yourself attachments for mini tractors are real. We hope that our article inspired you to make your own homemade product. In the following articles, we will definitely dwell on the production of each type of attachment in detail and with drawings.