You can make a laser engraver with your own hands from improvised tools. Take a DVD drive or an inkjet printer as a basis. The devices are dismantled, the laser, cable and other elements are taken out. Then the device is assembled according to the instructions described in the article.

The content of the article

- Preparatory stage

- main stage

- Testing

Preparatory stage

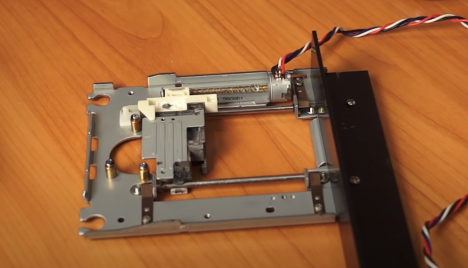

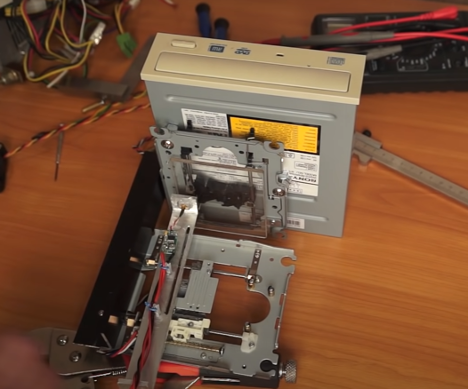

You can make a laser engraver with your own hands from DVD drives. To do this, they act like this:

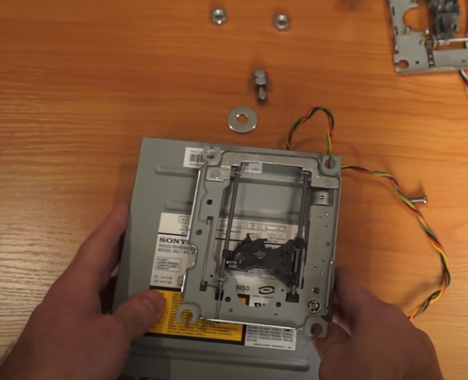

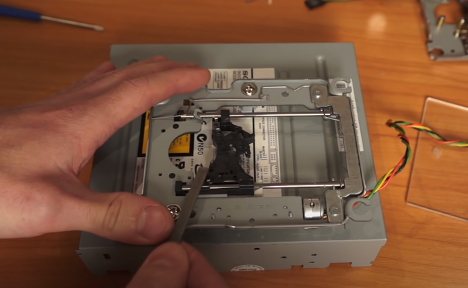

- Remove the drive cover.

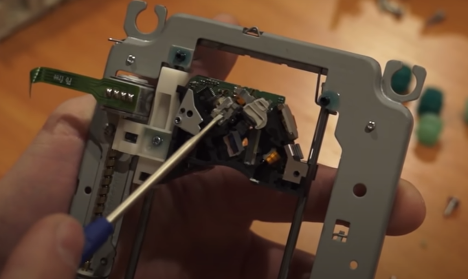

- Remove the housing with a screwdriver.

- Remove the inside of the drive mechanism.

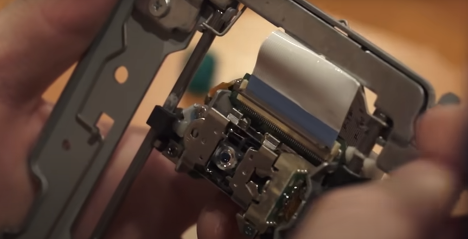

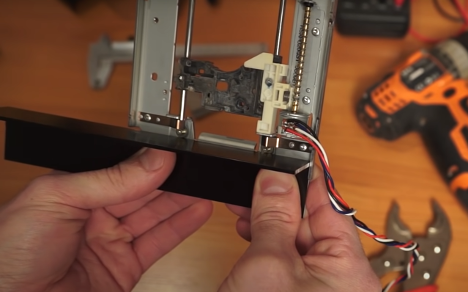

- Of the 2 lasers, only one is of interest - on its basis, you can design an engraver with your own hands.

- Bite off the cable from the engine.

- Solder to the remaining fragment.

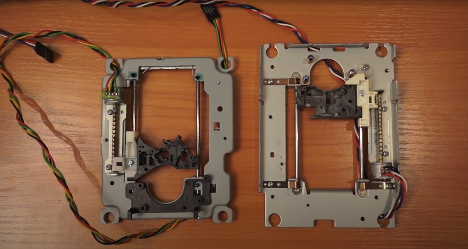

- As a result, 2 such blanks should be obtained.

main stage

Next, they act like this:

- Take an aluminum corner 40 * 40 mm and align it with the body as accurately as possible.

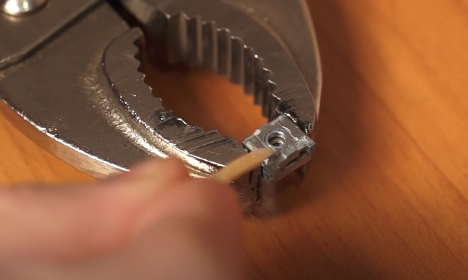

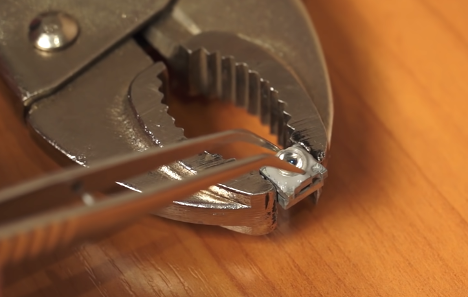

- Clamp with a hand vise and drill holes.

- Screw self-tapping screws into them.

- Drill holes in the second workpiece.

- Set perpendicular to the first workpiece and clamp with a hand vise.

- And drill a hole.

- Fasten the bolts with nuts and washers in them.

- Fix both parts together.

- You will get such a preparation.

- Clean surfaces with a file.

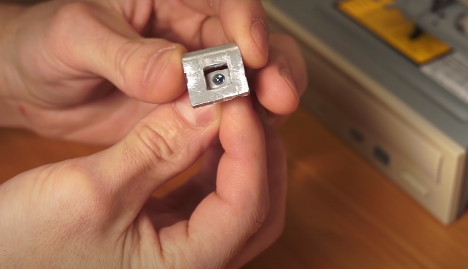

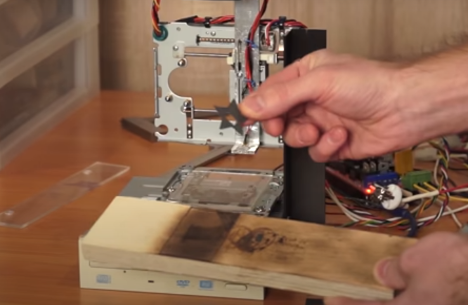

- Make a bracket for mounting the laser.

- Place the adapter plate on the carriage and screw it on.

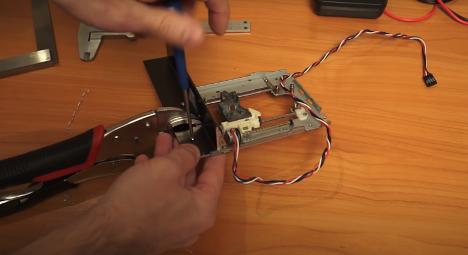

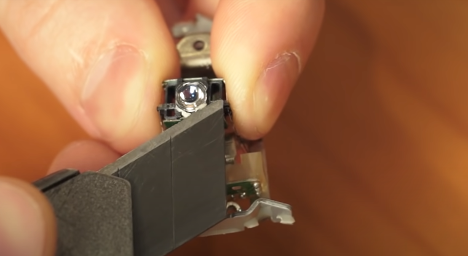

- Get a laser diode.

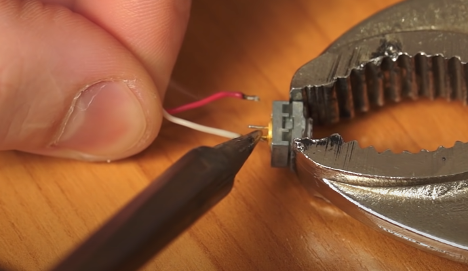

- It only has 2 pins. It is necessary to take the optical head and carefully remove the glue.

- Apply glue to the laser diode.

- Apply glue.

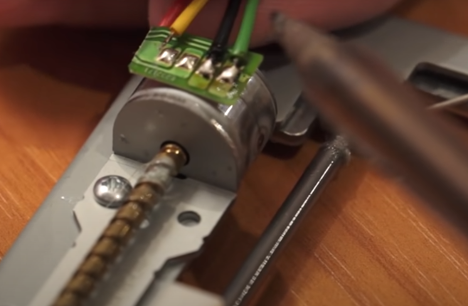

- Solder the wires to the laser diode.

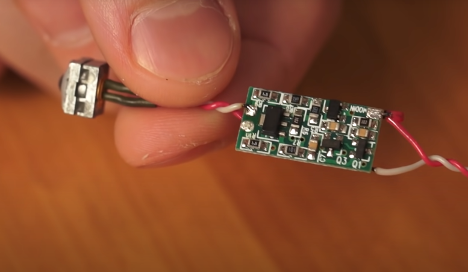

- Solder the laser diode to the current stabilizer. Get this detail.

- The next step in the instructions on how to make a laser engraver with your own hands is related to the manufacture of the bracket.

- Glue the laser with thermal paste.

Testing

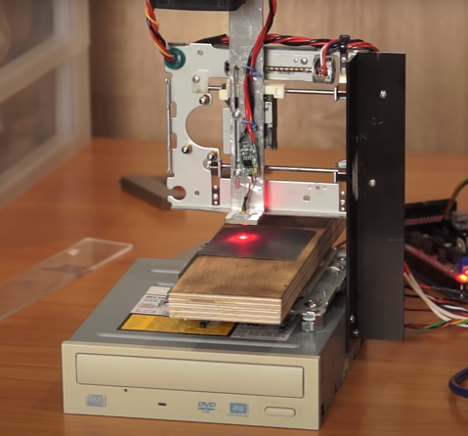

At the final stage, you need to assemble and test the device, the instruction is as follows:

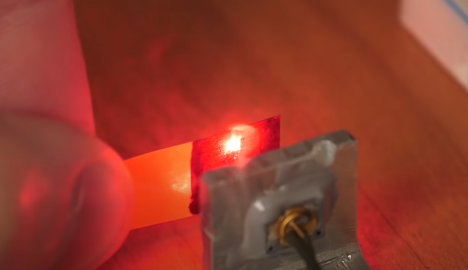

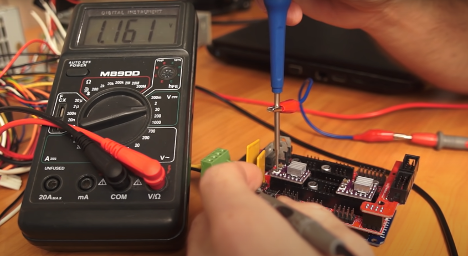

- After everything dries, it is necessary to check the circuit for operability.

- In this case, the laser works normally.

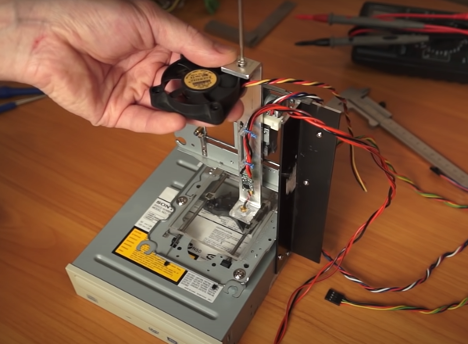

- Install laser.

- Mount a fan to blow off the smoke from burning.

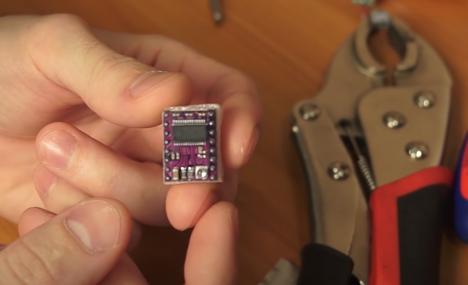

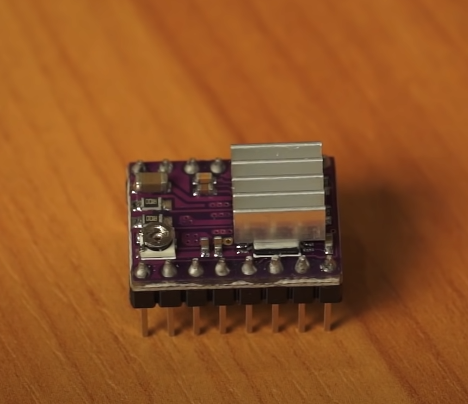

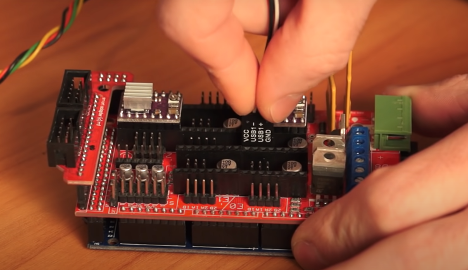

- Take motor drivers.

- After wiping the heatsink and microcircuit with alcohol, apply thermal paste and glue them together.

- Install the motor drivers on the expansion board.

- Without connecting the motors, measure the voltage.

- Connect motors via USB connectors.

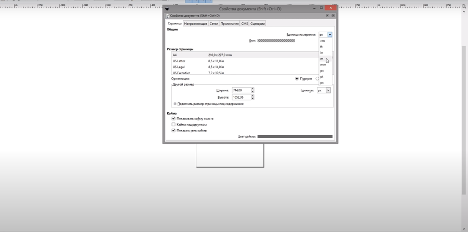

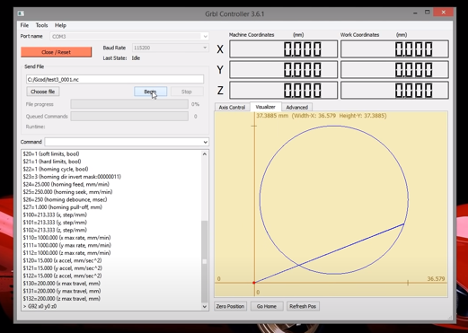

- Launch Inkscape on your computer.

- Create and customize a figure for engraving.

- Test the operation of the device.

- It turned out such a picture.

You can make a laser engraver with your own hands and from an inkjet printer. In this case, the assembly scheme is about the same. First make a carriage, then install the motors, test the voltage. Install the software and burn the part.

Thus, a homemade laser engraver can be designed with your own hands. To do this, you will need old devices, such as a printer or a DVD drive. During work, you need to carefully mount each detail, the quality of the engraving will depend on this.