Do-it-yourself welding of polyethylene pipes is carried out using a soldering iron with a coupling. Surfaces must first be cleaned of dirt and grease stains. A full description of the process and common welding methods can be found in this article.

The content of the article

- General recommendations for welding

- Sleeve welding

- Electrofusion welding

- Butt welding

General recommendations for welding

Welding of a polyethylene pipe is carried out in different ways, but in order to obtain the desired result, it is important to follow a few rules:

- Use only quality products that have certificates of conformity. Otherwise, they will not fit well, and the structure will turn out to be fragile.

- The internal gaps (diameters in section) of different segments must completely coincide with an accuracy of 1 mm.

- Regardless of the selected pipe, both ends of it are carefully cleaned of dirt and degreased before welding.

- The procedure is carried out only in a room with moderate humidity and without drafts. It is better not to work outdoors.

- After both elements are connected, it is required to ensure complete immobility until complete cooling.

- You also need to work away from the window so that direct sunlight does not fall on the pipes.

Sleeve welding

One of the ways to weld polyethylene pipes is called coupling (that is, socket welding). This is due to the fact that in this case a household soldering iron with a coupling is used, where the pipes are inserted. Moreover, their diameter should be no more than 63 mm.

The sequence of actions during operation is as follows:

- Put the welding machine on the platform and fix the legs.

- Installed on the surface to heat the nozzle of the appropriate diameter.

- Adjust the temperature in the range of 220-230 degrees.

- Prepared and cleaned pipes are attached to nozzles, allowed to hold for literally 5 seconds so that the plastic melts.

- Immediately after this, you need to connect the two fragments with a confident, but unsharp movement until they stop and hold for 10-15 seconds.

Electrofusion welding

This type of welding is used if the pipes have different parameters - wall thickness, outer and inner diameter. It is also used during the installation of the sewer system. The technology is quite complex, so certain skills are required. The main steps are:

- Prepare pipes, clean them from dirt and grease stains.

- Clean the internal surfaces of the electrical coupling. To do this, it is best to use wipes that are soaked in technical alcohol.

- The ends of the pipes are cut evenly so that the edges are strictly perpendicular.

- They put pipes at the joints, put on an electric coupling and set the temperature in the range of 220-230 degrees.

- Connect both fragments together and hold for a few seconds. Allow to cool completely so as not to dislodge the fresh seam.

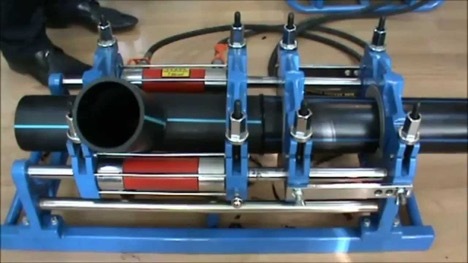

Butt welding

Pipes can be butt welded. To do this, use special equipment - a mechanical or hydraulic drive. In fact, this is a professional welding that allows you to get a perfectly even joint. The main steps are:

- Selection and preparation of the pipe surface (it is best to take products from one pair, that is, ideally identical).

- Putting the ends of the pipe on the plate and heating at a temperature of 220-230 degrees.

- Squeeze and hold for a few seconds.

Then the pipes are allowed to lie down until completely cooled. Thus, the considered technology is suitable only for professional purposes, since it requires the use of special equipment. At home, products are welded on a conventional soldering iron with a clutch.