Soldering iron is a hand tool that is used for soldering and tinning. It usually consists of a metal heating element that heats a rod and melts solder, such as rosin. As a result, soldering of contacts to a metal surface occurs. The design and operating principle of this device is described below.

The content of the article

- Design and principle of operation

- Types of soldering irons

Design and principle of operation

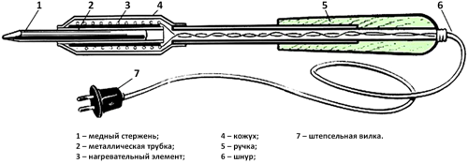

A soldering iron is a simple heating device, the basis of which is a copper rod. It is inserted into a metal tube, inside of which there is also a heating element. At the other end there is a casing with a handle and a cord on which a plug is mounted to connect the tool to the network. The soldering iron device is shown in the figure.

From this diagram it is quite easy to understand what a soldering iron is and how it works. The tool is plugged in and wait until its working surface (tip) heats up. It reaches the desired temperature due to the contact of the heating element with a rod made of copper or other metal.

It’s clear what a soldering iron needs – just a heat source. Along with electricity, this can be an open fire or gas, in the flame of which the rod is held for 5-6 minutes. After this, the rod is ready for use - it is applied to the desired part and soldering begins using flux (rosin, tin, zinc chloride solution or other solders).

By exposing metal surfaces to hot temperatures, for example by contact, they are partially melted and soldered together. After stopping work, the metal freezes almost immediately, allowing the wire to connect to the surface. This is how a soldering iron works.

Types of soldering irons

The photo of the soldering iron above shows a classic rod-type model. This is the simplest device, equipped with a long handle with a sting fixed in it. It is most often used in everyday life, including for working in hard-to-reach places.

Along with the rod tool, there are two more types of tools:

- Gun – the tip is located at right angles to the handle. The operating principle of this type of soldering iron is exactly the same. But it is used more often in repair and electrical work.

- Soldering Station - a complex system that consists of the soldering iron itself, as well as a control unit. They operate using different energies. For example, infrared ones operate using radiation, hot air ones use hot jets, and digital ones are equipped with a transformer.

There is also an important classification related to the heating principle:

-

Nichrome – has a wire made of the same material through which current passes. What this type of soldering iron looks like is shown below. It is affordable, impact resistant and durable. At the same time, it heats up for a long time, and if the spiral burns out, the tool will completely fail. The device is suitable only for household tasks and infrequent use.

- Pulse - a device equipped with a frequency converter and transformer, as well as a tip. The way this type of soldering iron works is by increasing the frequency of the voltage, i.e. under impulse influence. Thanks to this, it heats up very quickly, and the power can be adjusted. This tool allows you to solder both small and large parts. But the work should be short-lived.

- What other types of soldering irons are there? ceramic. Their heating element is not made of metal, but of ceramics. Due to this, it does not burn out and works for years. Heats up quickly enough and holds heat well. However, ceramic rods cannot withstand strong impacts.

- Induction – devices in which an inductor coil is installed. The rod has a coating of ferromagnetic composition, due to which a magnetic field is formed when turned on. This is what heats up the core. Moreover, the heating temperature is maintained automatically, and figuring out how to use this type of soldering iron is very simple.

We can say about a soldering iron that it is a heating device that is used mainly for household tasks. Most tools are used only at home, although there is also professional equipment - soldering stations. They are used only for large volumes of work.