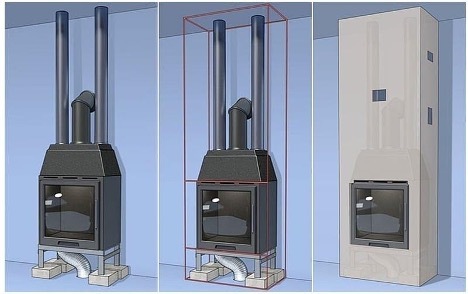

Before you start lining the fireplace insert box, you need to properly plan and build the box itself. This includes choosing a suitable location, ensuring security and taking into account the characteristics of your premises. Creating a DIY fireplace box begins with designing the size and shape to suit your fireplace and room decor.

When building a fireplace box, it is important to consider the following aspects:

- The location of the box relative to the fireplace and the safe distance from the fire.

- The dimensions of the box correspond to the dimensions of the fireplace insert.

- Use of fire-resistant materials to prevent fire.

The content of the article

-

Selection of materials

- Tools and materials for work

- Errors when installing a fireplace insert box

- Shutdown

Selection of materials

The choice of materials for finishing the fireplace box is of great importance. Drywall is a popular choice due to its plasticity, ease of processing and good decorative properties. Cladding a fireplace with plasterboard allows you to create an aesthetic and modern finish that will harmoniously fit into the interior.

Drywall for fireplace surrounds offers the following benefits:

- ease of installation and processing;

- the ability to create various shapes and designs;

- good thermal insulation properties.

Tools and materials for work

To line a fireplace insert with plasterboard, you will need the following tools and materials:

- plasterboard sheets;

- profiles for the frame;

- screws and dowels;

- level, tape measure, hacksaw or jigsaw;

- putty and spatula for sealing seams.

Step-by-step installation instructions:

- The first step is to create a frame for the fireplace box from metal profiles. The frame must exactly match the size and shape of the future box.

- Once the frame is ready, proceed to installing the plasterboard sheets, carefully screwing them to the profiles. If necessary, drywall can be cut to create the desired shapes and angles.

- After installing the drywall, all seams and joints should be carefully puttied to obtain a smooth surface. After the putty has dried, the box can be painted or decorated in another way that matches your interior.

Errors when installing a fireplace insert box

One of the most common mistakes is insufficient compliance with fire safety requirements, in particular, ignoring the required distance from the fireplace insert to combustible materials. This can lead to overheating of the box materials and, as a result, to a fire.

Choosing the wrong materials for your fireplace insert is also a common mistake. The use of materials that are not designed for high temperatures or do not have sufficient strength and fire resistance can lead to deformation of the box and even its destruction. In addition, incorrect application of drywall or its processing without taking into account technical features can reduce the effectiveness and durability of the structure.

Finally, errors in the design and installation of the fireplace box can lead to a number of problems. Insufficient frame strength, incorrect arrangement of elements or insufficient fastening can lead to the collapse of the structure. It is also important to consider the need for adequate ventilation in the fireplace area to prevent overheating and ensure efficient heat distribution. Failure to comply with these points may negatively affect the functionality and safety of the fireplace as a whole.

Shutdown

After completing the main installation and finishing work, the box above the fireplace can be further decorated. This could be the installation of decorative elements, lighting or other accessories that will highlight the style of your interior and add comfort to the room. Creating a fireplace convection duct not only improves the appearance of the fireplace, but can also help distribute heat better throughout the room.

Thus, a do-it-yourself plasterboard fireplace box is not only practical, but also an aesthetically attractive solution that will allow you to enjoy the warmth and comfort of your fireplace in to the fullest.