Almost all ventilation systems include a condensing unit, which is responsible for heating or cooling the air. KKB is in the class of non-autonomous air conditioners.

In it, the refrigerant in the state of a liquid passes the preparatory stage, and then enters the heat exchanger and evaporates.

In this material we will talk about the principles of operation of this equipment, dwell in detail on the nuances of its selection and some of the features of installation.

The content of the article:

-

Condensing unit components

- The advantages of the condensing unit

-

Nuances of KKB selection

- Recommendations for the selection of filter driers

- How to choose a sight glass?

- The choice of thermostatic valve

- Solenoid valve selection

- Varieties of condensing units

-

The principle of functioning of KKB

- KKB air cooled

- Water cooled unit

- Features mounting KKB

- Reputable KKB Manufacturers

- Conclusions and useful video on the topic

Condensing unit components

KKB - monoblock with compactly housed in it nodes. They are used in tandem with supply ventilation devices, with

split systems any type equipped with internal units or direct cooling systems. They can replace the chiller when the installation of the latter is impossible due to the heavy load on the roof.The main elements of this significant part of the ventilation system are:

- compressor;

- engine;

- centrifugal or axial fan;

- a heat exchanger acting as a condenser;

- power supply system;

- control system.

Additionally, KKB is completed with connectors that enhance its performance and consist of a choke, a special filter, a solenoid valve, and a sight glass. Modern KKB models work on ozone-friendly refrigerants. They can circulate highly environmentally friendly freon R-22, R-407C, R-410a. They are suitable for any ventilation systems, as well as for duct coolers.

The kompressono-kondensatny block is mounted both inside, and outside. Manufacturers usually equip the unit with protection against voltage and pressure drops.

The internal elements of the KKB are insulated and grounded to avoid electrical injury. Manufacturers cover the surface of all nodes of the device with a corrosion-resistant coating. This allows it to operate in humid conditions.

The advantages of the condensing unit

If you compare KKB with chiller, then we can note the obvious advantages of the first:

- The production of one kW of cold is cheaper, because there is no intermediate coolant.

- Convenient adjustment. Each KKB is connected to a single inlet installation, therefore, control is exercised by means of standard controllers.

- Easy installation. No additional fans, air ducts and other elements are needed. Only installation of the heat exchanger of the evaporator is required.

KKB can be a component of a large ventilation system and a separate unit built into the unit. There are they stationary floor and wall mounted. Stationary blocks are placed near the buildings and on the roof.

The inclusion of KKB in the air conditioning system is the cheapest and most affordable solution.

A modern KKB compressor is equipped with protection against unstable operation of the power grid, moisture, mechanical damage, and high and low temperatures. All this disrupts the functioning of the unit. The housing, which encloses the unit, is made of galvanized steel, because it does not corrode.

In order to quickly cool down the device, manufacturers often complement the heat exchanger, condenser, lines with aluminum inserts. The heat exchanger is also protected from harmful effects - a special anti-corrosion alloy is applied to its surface.

In order to control the pressure inside the KKB, all elements in contact with the coolant are equipped with inspection nipples.

Despite these advantages, it is often the case that after installation KKB quickly fails or is not included in the work at all. Experts point to one reason. This is an illiterate selection of the compressor-compensatory unit and the evaporator.

Nuances of KKB selection

Most often, a condensing unit suitable for specific circumstances is selected for power. To do this, you will have to perform a standard calculation based on the performance of the ventilation unit in mᶾ / hour, temperature, outside air humidity during the summer period, and supply air temperature. This parameter plus humidity is selected for a particular region according to the SNiP.

The first parameter takes 6 degrees less than the optimum temperature in the room. In addition to these values, you will have to use the id diagram. Then, all the parameters found are substituted into the formula: Qhol = 1.2xLx (Inar-Iprit) / 3600.

The photo shows a psychometric i-d diagram of moist air. It can be used on the basis of two known values to determine the remaining parameters of the air, including the flow rate of cold without complicated calculations.

In order to completely do without calculations, sometimes they use a simplified method. It has been established that for every 10 m² and the height of the room 3 m, 1 kW of cold is needed. If the floor space is 200 m², a block of 20 kW is required.

Experts advise to pay attention to several nuances that are important for the correct selection of the unit. In order to guarantee the effective work of KKB, it is necessary to rely on it not on the maximum temperature condition of the outside air, but on the minimum provided for by the range of work of the KKB.

If you perform a calculation on the maximum air temperature outside, the unit will be able to work normally when the temperature outside is equal to the calculated or rises above this value. When its value falls, there will be such a phenomenon as soon as the partial boiling of the refrigerant in the evaporator. The liquid freon will return to the suction of the compressor. This will be followed by jamming of the latter.

For normal operation, the compressor capacity must be lower than the maximum evaporator capacity. The coupling kit is not always sold with a condensing unit. Sometimes you need to pick it up yourself, but for this you need to know the technical features of the elements included in this strapping unit.

Recommendations for the selection of filter driers

This site is necessary to absorb moisture, various unnecessary impurities from the freon highway. The choice of it is carried out according to the tables of manufacturers, taking into account the brand of refrigerant. In addition, it is important to know in advance how this element will be installed - by soldering, under flanging, at fittings. The connecting dimensions will depend on it.

This strapping element is responsible for maintaining the cleanliness of the refrigerant circuit. Only the filter of good quality copes well with this task.

Affects filter selection and fluid performance, which affects the interval between replacements. It is also important how the KKB will function - exclusively for cold or heat. In the first case, the freon will move in one direction, in the second - in both.

How to choose a sight glass?

This element is necessary to control the level of freon filling, the state of the filter, the presence of moisture in the circuit. When choosing it, they proceed from the brand of freon, the ambient temperature, the method of mounting the glass, the presence of a moisture indicator, a critical level of humidity.

If R407C or R410A freon circulates along the contour, then the polyester oil for these grades can form acid and alcohol when interacting with water. This is signaled by the changed color of the sight glass, which will help prevent the compressor from seizing as a result of the decomposition of the oil. The green color of the indicator indicates the normal state of the refrigeration circuit.

A shift towards a yellow tint indicates that the refrigeration circuit must be monitored more closely. A fully yellow indicator indicates an unacceptable amount of moisture in the circuit. After the measures taken to remove it, the filter will have to be changed.

The choice of thermostatic valve

The expansion valve regulates the flow of refrigerant from the unit to the evaporator for cooling. Choose it according to the type of refrigerant, the nominal cooling capacity, boiling point, subcooling, condensation. Take into account and the temperature level of the working environment - the maximum and minimum.

TRV - an important element of the refrigeration circuit. There are two types of thermostatic valves - with equalization of external and internal. He is assigned the role of the refrigerant supply controller to the evaporator. He is also responsible for its expansion, leading to a decrease in pressure and temperature.

Influences the choice and method of pressure equalization - internal or external. It is necessary to know how the installation of TRV will be made. It is usually installed under the soldering, flanging or on the fittings.

Solenoid valve selection

The choice of this element is influenced by the brand of freon, the maximum indicators of working temperature and pressure. Another important parameter is the peak value of the opening differential pressure. Attention should be paid to the connecting dimensions, performance.

Accounting is subject to the coefficient Ku, which takes into account changes in the flow rate of the working medium when the pressure difference on solenoid valve will be 1 Bar.

Varieties of condensing units

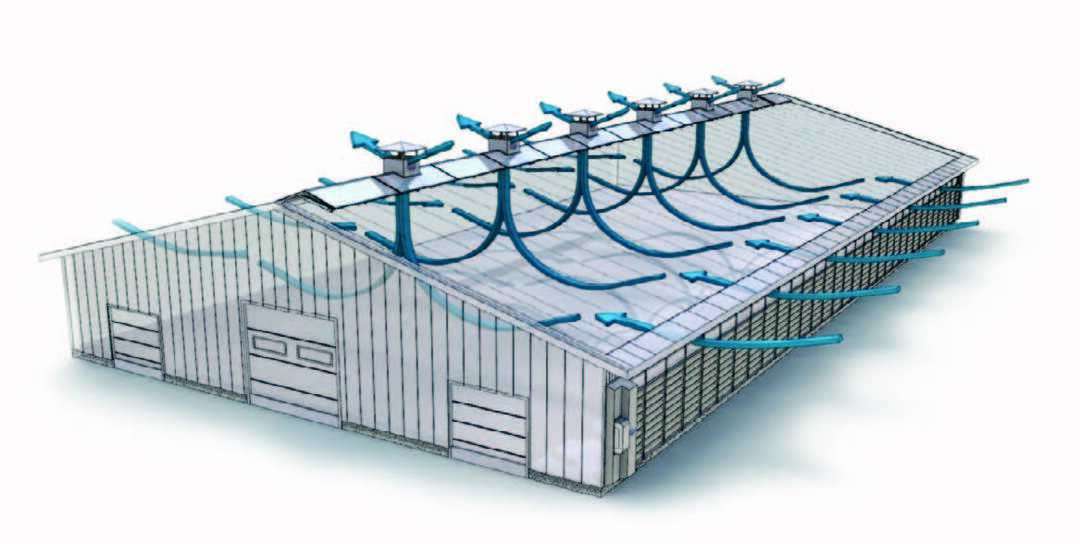

KKB type is determined by the type of its own cooling. It can be carried out with the help of air, water, external cooler. The units of the first type have a built-in fan that forms the air flow.

If an axial fan is included in the design, the unit is mounted outside the building. In the presence of a centrifugal fan, the installation of the unit is carried out directly in the room.

The capacity of air cooled KKB can be very large - up to 45 kW per hour. In everyday life, an aggregate with a maximum power of 8 kW is usually sufficient.

The condensing unit, in which the condenser is cooled with water, is more powerful. It does not require a large amount of air for its operation; therefore, it is compact and designed for indoor installation. Its installation is possible at a considerable distance.

KKB with a remote type capacitor is used less frequently, mainly when there is not enough space in the room. In this case, the actual unit is installed inside the room. The heat exchanger is placed outside.

The principle of functioning of KKB

The work of the condensing unit is based on the law of physics on the absorption of thermal energy when changing the state of the refrigerant from a liquid state to another aggregate form. When the process proceeds in the opposite direction, previously accumulated thermal energy is released and transferred to the consumer.

When KKB works for cooling, freon is evaporated inside the heat exchanger, then condensation occurs. When heating is the opposite.

Turn on and off the unit, as well as regulate the power of the air flow through the control system. To connect it to KKB there are special tires and sensors

While the installation of the chiller system allows you to individually set the temperature conditions for each room, the temperature will have the same value when using KKB. Ask it on the main thermostat for the entire building.

KKB air cooled

The refrigeration circuit has 2 heat exchangers. One of them - the condenser heat exchanger, is located in the KKB itself. The second - the evaporator heat exchanger, is located in the air cooler of the central air conditioner. In addition to these nodes in the refrigerant circuit includes a compressor enclosed in the housing KKB.

Also, its elements are filter drier, TPV, viewing glass. The last three elements are located on the inter-unit fluid line near the evaporator.

Unlike other components of the refrigerant circuit, the cross section for the passage of freon in a thermal expansion valve is small. Its adjustment depends on the evaporation temperature of the freon in the heat exchanger and the magnitude of the pressure. To TRV, compressed freon gas in a condenser heat exchanger has an overpressure injected by a compressor. After TRV - in the heat exchanger of the evaporator, the pressure decreases.

In the condenser, the refrigerant, having lost heat to the surrounding space, is condensed. After returning a portion of the heat energy, freon is still under increased pressure, but only until the passage of the thermo-expansion valve. After that, the pressure drops sharply and cooling occurs.

Most often KKB equip the condenser of air cooling. The inlet and outlet piping of the unit are equipped with shut-off valves to prevent moisture or external contamination from entering.

Under the influence of the centrifugal fan of the main air conditioner, the heat exchange surface of the evaporator is heated. It acquires a high temperature and passes into the gaseous phase and before that a liquid refrigerant circulating in the evaporator. At the same time, it absorbs heat from the supply air, thereby cooling it.

After the refrigerant in the form of gas is again in the compressor, shrinking, transformed into a liquid state of aggregation and the process of circulation resumes.

Water cooled unit

The KKB installation with water cooling provides for preliminary hydraulic calculations and professional installation. The cost of these blocks is higher than that of air analogues. This is explained by the need for additional costs for the device cooling tower, laying the circuit to it, the purchase of pumps.

These units are designed for installation inside the building. The condenser is cooled here with the help of a liquid that makes a circular revolution in a closed circuit. A cooling tower is installed outside - wet or dry, or running water is used.

This climatic equipment has an additional heat exchanger. It cools the coolant and, taking away the heat partially, heats the circulating water, which can then be reused. Its use in the heating system for hot water supply justifies several large investments in the purchase of equipment of this type.

Water-cooled KKB can be mounted in tall buildings. Such units are ideal for coastal areas, because internal installation protects them from the impact of the aggressive environment

The advantage of water-cooled units is their higher power and the possibility and prospect of increasing the distance between the unit and the cooling tower as far as is convenient. If running water is used as a cooler, the cost of air conditioning drops significantly.

Features mounting KKB

The installation of the condensing unit must be preceded by thorough preparation. First of all, it is checked that the unit data such as phase connection, voltage, current frequency correspond to the characteristics of the power supply line.

In a place where they plan to install KKB there should be no dust, otherwise it may get into the heat exchanger. The airflow from the condenser should not return to it.

The installation process of the ventilation system begins with the installation of floor KKB, evaporator, laying interconnecting highway. The most difficult moment is the installation of the expansion valve, dewatering filters, receivers, sight glasses, and other elements.

In case of installation of the unit on the ground, it is necessary to arrange it so that rainwater and snow do not fall into it. The space around the unit should be free, without obstacles to air movement and maintenance. Do not connect air ducts that supply and discharge air from the unit.

Assembly and installation of condensing units are performed by specialized firms whose employees have the appropriate qualifications and certificates. To connect the unit you need to have special tools and equipment. It also happens that the unit has to refuel or perform its full refueling.

Reputable KKB Manufacturers

KKB with high performance characteristics is produced by Italian company Aermec. The range includes professional air-cooled condensing units and equipment for home use.

Enjoy the popularity of KKB Aerotek, produced by the same international company based in Switzerland. The equipment parameters are fully selected for the Russian consumer.

The French company Airwell is famous for the quality of its equipment. No less popular are the Carrier units supplied to the market for climate technology by the American Carrier Corporation. Daikin from Japan has a representative office with us, whose climatic equipment is also in great demand.

Conclusions and useful video on the topic

Components of condensing unit:

Reasonable choice of condensing unit:

To provide excellent ventilation of the office, home or other premises, the condensing unit will be the best solution. The unit itself has a small weight and size, but this does not reduce its functionality. It is important not to violate the rules of operation and follow the instructions, then the unit will serve for many years.

If you have questions on the topic of the article, you can ask them in the block with comments, and we will try to give them an extremely clear answer. You can also leave a comment on this article or share advice on choosing KKB.