To ensure home necessary amount of hot water used additional device - indirect heating boiler (MKB). Its use can be considered one of the most rational and economically justified.

We will try to find out what kind of boiler piping arrangement indirect heating is most effective and how to connect the equipment to avoid common mistakes.

The content of the article:

-

Choosing boiler indirect heating

- Design features and principle of operation

- Benefits of control equipment

- Varieties of devices with additional functions

- The size of the tank and its significance

- Strapping apparatus nuances

- Connection principle with the priority

-

BKN scheme and connection rules

- Option # 1 - tying three-way valve

- Option # 2 - circuit with two circulation pumps

- Option # 3 - tying with low loss header

- Variant # 4 - The use of recirculation coolant

- Option # 5 - with a non-volatile boiler system

- Stroke connect the indirect heating boiler

- Conclusions and useful videos on the topic

Choosing boiler indirect heating

Before purchasing and connecting a buffer storage tank (also known as the BKN) should understand the structural features of the most popular types. The fact that there are many types of equipment, including combined models that work on the heating system and alternative sources of energy at the same time.

We consider the traditional boiler with the coil, using as a hot water heater.

Design features and principle of operation

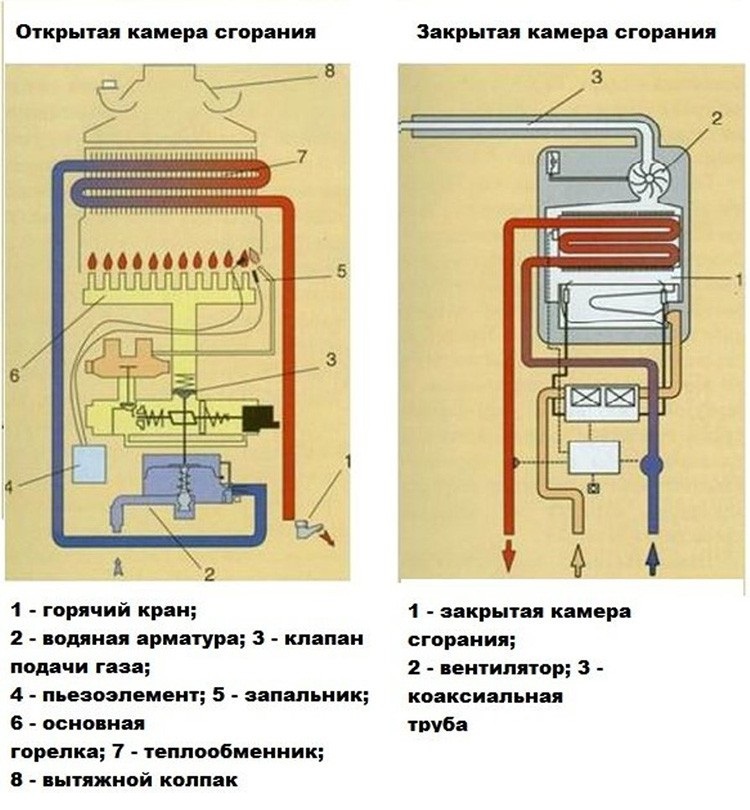

What does it mean indirect heating? Device with direct heating function by connection to an electricity or gas burner, in MKB other heat source. The water is heated by connecting to the WAN, that is, it turns out that the source is a heat carrier - hot water (or its substitute).

BKN externally resembles a standard water heater - that is, has a barrel-shaped, although modern models are more ergonomic. For ease of use and installation they give a rectangular configuration

If we look at new models of well known brands, we can see that the boilers and KN boilers often have the same design. They are mounted side by side or one above the other - so you can save on accommodation area.

The main element that performs the heating function, - steel or brass exchanger (coil) with high surface area, which is located inside a metal coated with a protective layer enamel tank. To the cooling water is not going too fast, the outside of the enclosure is surrounded by a layer of insulation, and some models - and the housing.

If you want to keep the water in the boiler is heated quickly, choose a model with several heat exchangers, and slowly cooled down to - with high-quality thermal insulation

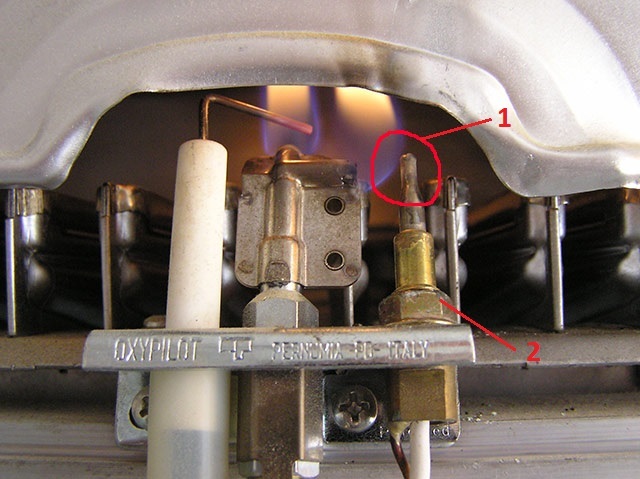

An important detail, which is now equipped with most of the heating devices is a magnesium anode. Rod, fixed in the upper part of the device, protect metal parts from corrosion formation, resulting in the water heater is much longer.

Barriers of a high-pressure action is safety valve and built-in thermostat. If the tank is not equipped with the security group, it is set apart, in the regeneration of the binding.

image gallery

Photo of

Indirect heating boiler is connected to three communication systems: Cold water for heating and hot water branch

Indirect heating boiler - economical equipment. He does not generate the heat, for the preparation of hot water heat transfer medium therein corresponds, recruited from the heating system

Indirect heating boiler provides the supply of hot water a stable temperature at any time. However, due to the fact that the hot water is not used at night, in an expansion tank for hot water must be enabled

Upon reaching the required DHW temperature sensor is triggered, which is a command to overlap the coolant. It will not come into the boiler until the water temperature is decreased to the limit values

Boiler connection to utilities

Work cylinder paired with a boiler

Applications in piping expansion tank

Automatic indirect boiler

Often the water circulating in the heating system does not exceed 65-70 ° C.. Many doubt of its effectiveness when it acts as a heat source for heating in MKB. In fact, this temperature is enough, because the speed and magnitude of heat transfer depends on the area (rather large) contact with water coil.

How is the process of heating? Cold water intended for heating is supplied through a separate hole and fills the entire container. From the boiler to the heat exchanger and the water flows, but heated. Hot wall coils transfer heat cold water, which at the outlet has a temperature suitable for showering or dishwashing.

Benefits of control equipment

Ability to manage - a characteristic that influences the assembly of all the water heating system. There are two types of BKN: simple (cheaper) and with built-in control function.

Control heating process is required, if the main heating device - e.g., gas or solid fuel boiler - not control unit

A distinctive feature control models is additional equipment temperature sensor and to supply / stop supplying water to the heat exchanger. Such equipment is in automatic mode.

To start you need to connect:

- input / output for hot water from the hot water;

- supplying cold water into the tank;

- manifold for distributing the heated liquid at the outlet.

After that can run the boiler - the water begins to heat up.

If the boiler is operating in automatic mode, in the management of the boiler is not necessary. But it is still better to equip the temperature sensor for this purpose is provided in the housing

The process of connecting and binding indirect heating boiler going one way (described - below).

How management can influence the temperature of the water? Virtually nothing. The maximum value of which can reach the temperature at the outlet does not exceed the parameters of the coolant in the heating system. Rather, it will be lower at 1-2 ° C.

If necessary a more intense heating (this can occur if the boiler normally operates in the low temperature mode), it is best to choose a model with a built-TAN.

This equipment is suitable to buy with boilers running on solid fuel (water remains hot even after cooling of the boiler).

Varieties of devices with additional functions

Tanks with simple structure - this is only part of the range presented in the heating equipment market. There are many boiler modelsWhose functions are very useful for the integration into the domestic hot water system.

For example, one of the purposes of the more expensive models - the accumulation of heat. If possible power outages or daily consumer tariffs are too high, the accumulation mode is very useful. Structural features such models - reinforced thermal insulation and increased volume of the tank (300 liters or more).

Another embodiment that implements most rapid supply of hot water to the draw-off points, - the boiler recirculation. Unlike conventional designs, this has three nozzles posts with tap water. For two hot running water, one - cold. the water is supplied by a pump.

When using a recirculating model can be useful to arrange an additional circuit, e.g., for mounting the towel dryer.

Less than with the coil device, there are models of the "tank in tank". A container of water which must be heated, is located inside a heating circuit - outside

The water in this tank heats up faster than the units with a heat exchanger, but also the value it above.

The size of the tank and its significance

Cylindrical and cubic tanks differ in their size. Their volume is specified in liters: there are small models of 80-100 liters, but there are also cumbersome for up to 1400-1500 liters. The size is selected based on the needs of families in hot water.

Dimensions are important during installation. For wall mounting only suitable lightweight model - up to 200 liters, the rest are outdoor execution. Both horizontal and vertical wall unit supplied with a special attachment, floor fitted with legs or a small stand.

Connections required to connect the water and coolant, usually derived from behind and from the top to make it easier to attach the tank to the pipes. The front panel of a number of models equipped with a temperature sensor (relays) and technical hole

Rectangular units occupy a little less space than cylindrical, due to the tight junction pipes.

Strapping apparatus nuances

Easier to do the wiring and piping, boiler if CN is set with the boiler, pumps, other equipment involved in the assembly of the DHW system. Embedding auxiliary device has an existing network is much more difficult.

In any case, for the normal operation of the instrument will have to perform a number of rules:

- to choose the place of installation - as close as possible to the boiler;

- to provide a smooth surface for the boiler installation;

- for protection from thermal expansion set membrane pressure accumulator (output of the heated water), whose volume is not less than 1/10 of the volume BKN;

- equip each circuit ball valve - for easy and safe maintenance of devices (e.g., three-way valve, pump or the boiler itself);

- for protection against backflow of the water supply pipes install check valves;

- improve the water quality by tapping filters;

- correctly positioned the pump (or several pumps) - motor axis must be in a horizontal position.

For security reasons, you can not try to fix the heavy device on plasterboard or thin wooden walls. Suitable are the walls made of concrete and brick. Brackets or other holders of fixed braces, anchors, dowels.

Regardless of the type of device - a floor or wall - if possible, it is mounted above the level at which the boiler is installed, or at the same level. For outdoor can make a pedestal or a sturdy platform to 1 m tall

When installing the pipes is directed towards the boiler (even if the rear of the mask or falshstenoy). You can not use unreliable equipment, such as corrugated hoses that can not withstand the pressure and water pressure.

For normal operation, the storage water heater of indirect heating in the strapping following functional devices should be included:

image gallery

Photo of

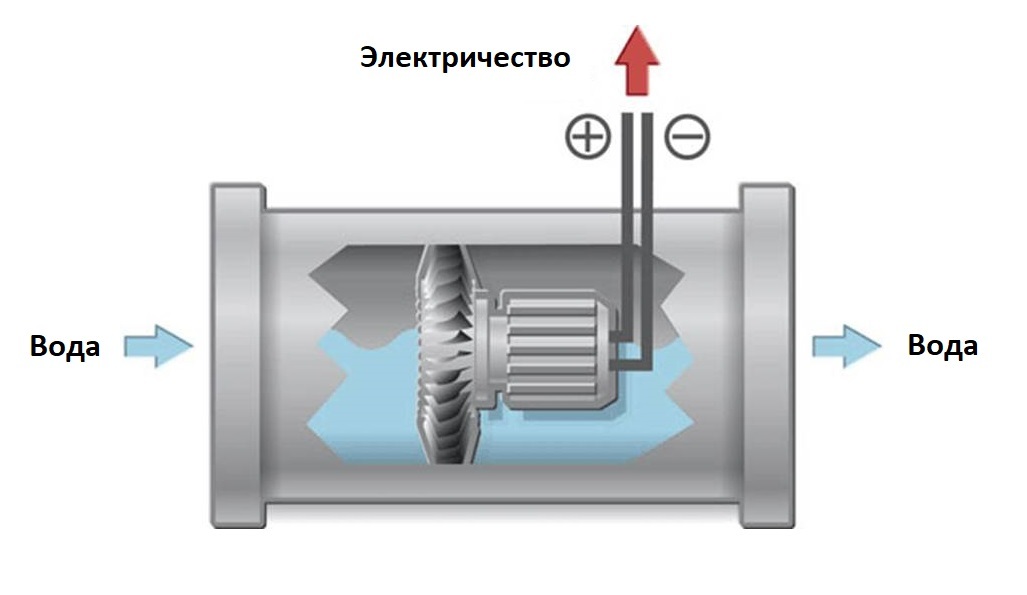

Complicated technical system should be equipped with a pump is supplied to the hot sanitary water faucets and stimulating the movement of the coolant for heating a branch, as well as water heating circuit boiler

The cold water coming from a general or autonomous running water, before entering the boiler must pass through a purification filter or strainer system destroying lime salts. Filtering to prevent the formation of mineral sediments

After the sump or water filtration system shall be pressure reducer. However, it is necessary only if the pressure in the branch exceeds 6 bar

Before the entrance of cold water into the boiler needs a check valve which prevents reverse flow movement

In order to have the heating water was provision for expansion at a time when it is not used in piping and expansion tank include a safety pressure release valve

In order to taps did not act excessively hot water, threatening burns in the loop need to install three-way mixing valve. It will be mixed into hot water with cold portions, eventually to be water draw-off temperature required user

In order to "shirt" of heated sanitary water, heating of the heat carrier fed only if it has need, The two-way set the thermostat. The server is connected with its cylinder temperature sensor

If the flow of hot water in the house is large enough, it is advisable to buy a boiler with built-in additional instantaneous water heater or buy a separate device and include it in the delivery branch hot water. In case of shortage of work includes miniature protochnik and save the situation

Circulation and pressure pumps

Strainer for purifying the cold water

Reducer water pressure in the water supply

The check valve in front of the boiler

Safety valve and the membrane tank

Three-way mixing device

The two-way thermostat heating circuit

Additional flow heat exchanger

Connection principle with the priority

Before installing the boiler in the heating system of indirect heating, it is necessary to choose the principle of its connection: with or without priority. In the first case, when there is a need for a rapid preparation of a large amount of hot water, entire volume of coolant pumped through the coil MKB, whereby water is heated much faster.

After the water temperature reached the desired mark (measured thermostat), there is a redirection of flow to the radiators.

Connecting without priority does not allow the passage of the entire volume of coolant and boiler serves only part of the total flow. When equipment such circuit water is heated longer.

Wiring BKN without priority: the boiler is brought to a separate circuit, so the ability to cut off heat sinks (or other heating device) does not exist

The priority scheme is more efficient, since it allows quick heat necessary amount of water without damage to heating. If the heater turned off for 30-50 minutes in the room in such a short period of time the temperature hardly drops, but the heated water will suffice.

The only condition for the circuit diagram with a priority - powerful boiler.

BKN scheme and connection rules

Wiring installation features and indirect heating boiler depends on the device class and the heating system in the house. You need to select the right mounting location, focusing on the location of the boiler, inserting pumps and pre-existing wiring. Try to understand what you should consider when installing heating equipment.

Option # 1 - tying three-way valve

This is one of the most popular schemes, since when it is used there is a parallel connection of the heating system and the MKB, equipped with stop valves. Boiler must be installed around the boiler to feed the circulation pump punch, then the three-way valve.

This scheme is successfully applied if a number of heaters, for example, two different boiler.

Three-way valve - a kind of switch that is controlled by a thermostat. By lowering the temperature triggered automatic and the flow of coolant from the heating circuit is redirected to BKN

In fact, this system is a priority, which provides rapid heating of water in the boiler during complete shutdown of the radiator for a while. Once the temperature rises to a predetermined value, newly activated three-way valve and returns the coolant back on track - the heating system. This way of tying is useful to those who use the boiler in continuous operation

Option # 2 - circuit with two circulation pumps

If the boiler is rarely used (e.g., seasonal or on weekends), or there is a need in the water, a temperature lower than the heating system circuit used with two hot water heating system from forced circulation: Circuit embodiments, the technical stuff circulation pumps. The first feed pipe mounted on immediately before MKB, the second - on the heating circuit.

The circulating pump is energized through thermostat, therefore it begins to operate only when the temperature drops below the desired. heating acceleration occurs along with the inclusion of forced circulation

Three-way valve in this circuit is absent, piping fitted with simple connecting tees.

Option # 3 - tying with low loss header

This connection is used for bulk boilers (200 L or more) of branched and heating systems with a plurality of additional circuits. An example is the heating system in a two-story house, where in addition to multi-loop radiator network used warm floor.

Hydraulic distributor (gidrostrelka) is required to simplify the design of the heating system installation and avoid recirculation pumps for each heating branch

gidrostrelki equipment avoids thermal shock, since water pressure in each circuit is equal. Make their own harness rather difficult at this circuit, so it is best to consult a professional installer.

Variant # 4 - The use of recirculation coolant

Recirculation is useful when the present circuit, a constant need of supplying hot water - e.g., towel. If it is connected to the heating system, coolant will continue to circulate and dryer to operate and at the same time serve as a heater.

Application recirculation possesses one great advantage - is not necessary to wait, when the water heated to the desired temperature, it will always hot

But this scheme has disadvantages. The main thing - the increase in fuel costs, because it requires a constant heating in chilled water circuit. Another minus - mixing water in the boiler. Typically, hot water stored in the upper part, and thence supplied to the draw-off points, but here it is mixed with the cold, whereby the outlet temperature slightly below.

There are boilers models with built-in recirculation, that is ready to connect the pipes heated towel rail. But cheaper to buy a normal tank, applying for connection tees.

Option # 5 - with a non-volatile boiler system

A distinctive feature of this scheme - the installation of the boiler at a higher level than the boiler and heating devices. Preference is given to a wall-mounted models that can be hung at a height of 1 m above the floor.

Floor models specifically under the scheme inferior wall heating rate and quality. The water temperature is significantly lower (approximately as in the return pipe), hence, the hot water supply is less than

Nonvolatile type of heating based on the application of the laws of gravity, therefore, the coolant is circulated and during a power failure. In the normal mode it can connect circulation pumps.

Stroke connect the indirect heating boiler

After selecting a scheme, it is clear what kind of equipment is required. Besides the basic devices may require valves, ball valves, distributive combs valves (three-way or non-return).

Procedure:

- prepare the installation place (on the floor or on the wall);

- make wiring, denoting the red / blue hot / cold water outlets;

- embed tee and the pressure relief valve, securing the sealant compound;

- tie taps hot (above) and cold (below) water;

- connection to the power supply, set the thermostat and automatic;

- select the heating mode;

- test the connection.

These are general recommendations required to present the amount of work. When you connect a specific model should follow the instructions that came in the kit.

Conclusions and useful videos on the topic

How to determine the wiring diagram and install the equipment correctly, will prompt the following videos.

General information about the connection diagrams:

Practical advice on connection technology:

How to make a piping boiler Indirect heating can be found in the following video:

Professional Review boiler 80 l:

In addition to installation and connection of the BKN require regular maintenance. It consists in washing the inner cavity of the tank, the removal of sediments and sludge, replacing the magnesium anode. Care facilities do not require much effort. If the harness is made right, fast repair is not required, but if a problem occurs with the equipment is recommended to address to experts.

There were questions on the boiler piping indirect heating, or have found inaccuracies that advise our visitors? Please leave your comments below.