One of the priority components of the comfort room is a comfortable temperature, the achievement and maintenance of which would have been impossible without the presence of high-quality batteries. The most popular are considered steel radiators, characterized by a good thermal inertia, high reliability and heat dissipation.

The market offers different versions of such batteries. Before you select a suitable option, you need to understand the design and operational characteristics of each species, right?

The article details the advantages and disadvantages of different types of steel radiators, describes how to connect radiators and provides recommendations for their choice.

To make things easier, we have prepared an overview of domestic and foreign manufacturers whose products have proven the positive side and enjoys stable demand among customers.

The content of the article:

- What materials do battery?

- The main types of steel radiators

-

Panel heating devices

- Features panel radiators

- Power heaters

- Battery Connection Methods

- Pros and cons of panel radiators

-

Features tubular batteries

- Features tubular devices

- Strengths and weaknesses of batteries

- How to choose the right radiator

- Manufacturers of steel instruments

- Conclusions and useful videos on the topic

What materials do battery?

Radiators not only help create a pleasant temperature in the room, but also can become a real decoration of the room. They are fundamentally different from each other fabrication material.

great demand for these options on the heating equipment market:

- aluminum;

- bimetal;

- cast iron;

- copper;

- steel.

aluminum gears inherent light weight and modern appearance. A characteristic feature is the efficiency of energy spent on heating and ease of installation. Due to the thin walls of the battery is achieved fast warm-up and a high level of heat transfer.

A distinctive feature of the instrument panel operation is the absence of pressure shocks in the circuits, hammer and temperature fluctuations that are inherent in a central heating system particularly in the scan period and launch

bimetallic radiators- the models are used for the manufacture of steel and aluminum. A successful combination of metals provides a fast warm-up and increases the ability of opposition to the baric loads. This type of radiators is suitable for both stand-alone and central heating systems.

Iron equipment It characterized by a high degree of heat dissipation, reliability and durability. This unassuming contours, like the old, well-known since the Soviet era MC-140 models. And also produce a respectable model with upgraded and modified surfaces, smooth inside and outside.

Brass battery durable, but have a high enough price. Therefore, they are used quite rarely.

Steel heat exchanging devices characterized by simplicity of design which promotes convection heating.

For a more detailed acquaintance with steel radiators need to deal with their classification by type, familiar with the specifications and features of the installation work operation.

The main types of steel radiators

Steel is ideal for manufacturing radiators, due to the flexibility, strength, ductility, wear resistance. These devices can be distinguished by their shape and structure. According to the principle of the device can be divided into tubular and panel.

With regard to tubular steel radiators, they consist of rectangular or round tubes, and panel - of panels 1-2-3. For a decision on the selection of the optimal type of heater you need to fully understand the technical and structural characteristics of each of them.

Panel heating devices

Panel instruments successfully combine the function of the convector and radiator are different to the primitiveness of simple and efficient design.

Features panel radiators

Steel panel type battery provided in the form of two connected by welding plates. Due to airtight connection is created space for coolant circulation. Using spot welding ensures a high reliability of the weld.

Steel radiator panel type is easy to fit into the interior of any room

Upon contact with virtually any coolant views Steel corrodes, its physical deterioration can reach 0.1 mm.

Reduction of this negative indicator provided with a high quality paint, in the following ways:

- cathode electrophoresis - when the paint is applied on the surface of the device and under the influence of the current source with a negative deep penetrate into the pores of the material;

- anode electrophoresis - This type of staining is similar to the cathode occurs, only the surface has a positive charge;

- immersion - steel appliances just immersed in the color mixture.

The most advanced method is considered the cathode electrophoresis, successfully proven in many industries, including the painting of car bodies.

All panel radiators can be classified into types depending on the number of convector heat exchanger and the number of panels.

The main criteria that affect the type of steel instruments, are the number of panels and ribs

Panel guaranteed longer battery operating at a temperature of the coolant to 70 ° C. It is important that the maximum temperature of the liquid circulating in the system, does not exceed 100 ° C

Installation steel panel radiators consider that their operating pressure should be no higher than 10 bar. This figure is quite enough, when the house or apartment central heating - pressure in the system It is 9 bar.

Dimensions of steel radiators panel type may differ significantly

However, we must note that during line checks may momentarily before starting hammering in the system - Increase the pressure to 15 bar. Pressure test panel radiators of 13 bar, therefore they can not withstand the hydraulic shocks which exceed this value.

If a decision about installing panel heating equipment in rooms heated centrally, it is necessary to provide for the installation of special gear that will prevent critical the load on the radiator.

Power heaters

Battery power is determined by its design, size of the panels, their quantity. Thus, in the absence of a convector type models 10 and 20, heat radiation is provided by the panel itself.

But the presence of the convector allows you to create a thermal curtain, cutting with the cold air that comes from the window. A significant role in the formation of the power plays of the device size.

The presence of convector panel radiator allows you to create an effective thermal curtain

steel radiator length is in the range 0.4-3.0 m, and a height ranging from 0.3 m to 0.9 m. The most popular devices 21, 22 and 11 types.

They are, at a maximum size of 3 m, had the following characteristics:

- VKO 11 It has one convector panel with a 3.15 kW;

- VKO 21 It consists of two panels with convector capacity of 4.2 kw;

- VKO 22 - two panels with two convectors to 6.25 kW.

Another parameter that should not be neglected when choosing a steel radiator - is its depth. It is determined by the amount used in the apparatus sections.

Details on the calculation of the battery capacity and determination of their amount is given in this article.

Battery Connection Methods

In the market of panel radiators, which allow the implementation of a bottom and side connection to the pipe system. When you select the device need to be taken into consideration wiring diagramSince in different conditions and locations connected to the circuit may be required radiators both connection types.

Bottom connection allows you to hide the pipe loop in the wall or floor. It should be borne in mind that when the lower connecting maximally provided aesthetic interior side, the efficiency of the radiator is reduced by 15-20% due to losses.

When the bottom connection panel radiator heating system pipes can be easily hidden in a wall or floor

Installation work on the side connection is made much easier, and heat up. Side connection panel radiator to be connected to both the vertical risers, and along the floor to the passing loop.

Pros and cons of panel radiators

Battery panel type, as well as any equipment that has its own strengths and weaknesses. Their main advantage over counterparts from other materials - the cost and appearance. Especially these advantages noticeable when compared with copper or cast-iron models.

Advantages of panel construction are as follows:

- Reliability and simplicity of the device. The absence of complex elements minimizes the chance of breakage.

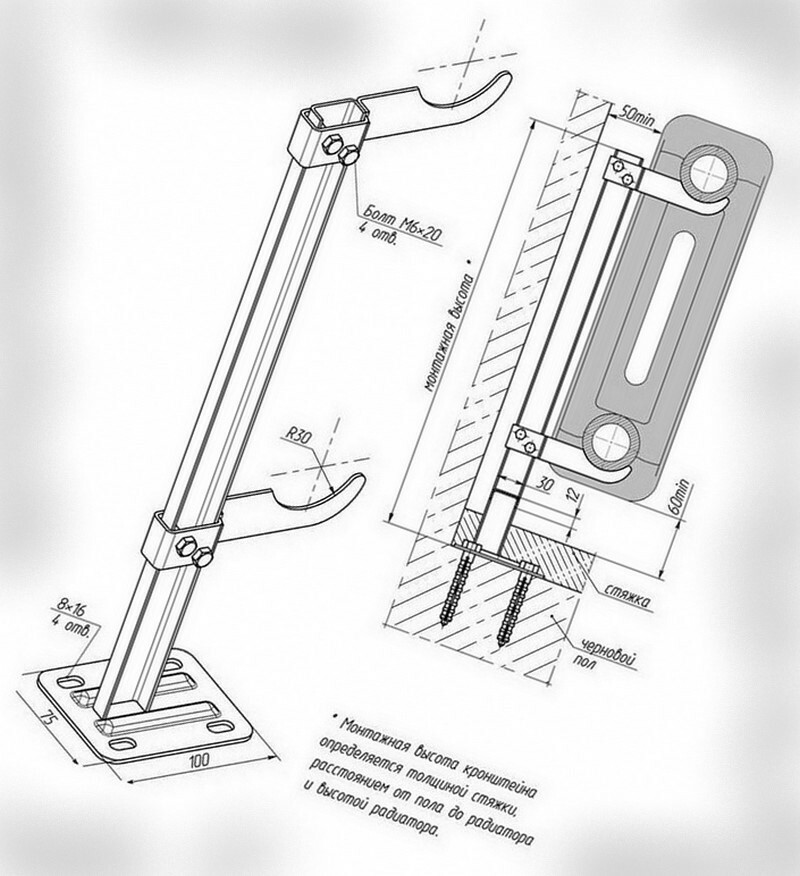

- Easy installation. Carry out the installation possible on their own. Also available as a lower connection to the contour and lateral.

- good heat dissipationWhich is achieved not only a large area of the battery, but also by convection.

- economy. Panel instrument models require a minimum amount of coolant in the heating which takes less energy. Saving, in comparison with the equipment of the iron may reach 30-40%.

- Presentable appearance - it allows you not to spend additional funds for the purchase, installation of decorative and protective screens.

- A wide range of - a rich range of different dimensions in length, depth, height devices.

It is obvious that the merits of the instrument panel is quite a lot, which explains their popularity and demand. But they do there are significant disadvantages. If this be neglected, can jeopardize the stable and reliable operation of the entire heating system.

Weaknesses panel type of equipment are as follows:

- The sensitivity of welds by waterhammer. With centralized heating safe operation is possible only when the gear unit, whose purpose is to mitigate the surge.

- Tendency to corrosion, Manifesting itself particularly acute at low as circulating liquid. Cycle six-month absence of water inherent in the central heating system, greatly accelerates the corrosion, reducing the term of service of the radiator.

- The probability of occurrence of defects - during transport and operation of the instrument panel is easy to scratch, which also can cause rapid corrosion.

Choosing steel panel radiators of the type necessary to consider all the details of their operation, especially when connected to a central heating system.

Features tubular batteries

Due to the higher cost of steel tubular batteries are used much less frequently panel. The design consists of several rows of parallel tubes. In this series may be arranged not only horizontally or vertically, but obliquely.

Features tubular devices

Under identical operating principle of the tubular equipment methods differ. Some sections are made as similar to cast iron, which are joined by welding. For other steel used rows of tubes connected to the lower and upper parts of the reservoirs.

The tubular heater is not difficult to turn into a significant element of the room decor

Although the design of tubular radiators and different, but almost all models have similar characteristics. This equipment is ideal for installation in heating systems in low-rise buildings.

Heat transfer tube radiators, compared with counterparts panel type more, but the price in this case is much higher.

Tubular radiators have the following specifications:

- working pressure of 15 atmospheres - during manufacture conducted two tests - with air and water tightness on the strength;

- able to withstand significant coolant temperature - up to 130 ° C;

- large variety of dimensions - depth from 40 to 290 mm, height from 190 to 3000 mm and length restrictions, and not at all;

- use for the manufacture of steel thickness from 1.32 to 1.5 mm;

- availability of taps to the side and bottom connection.

The inner walls of tubular devices often covered with a polymeric composition. This significantly extends their lifespan. The smooth surface prevents the accumulation of dust, so hygiene is beneficial tubular devices different from aluminum, iron and bimetallic analogs, which causes a lot of cleaning inconvenience.

Strengths and weaknesses of batteries

Tubular heaters models are appropriate for use in private homes, where the system heat stable and characterized by a low operating pressure without surges and water hammer.

Popularity tubular devices due to a set of positive qualities:

- High working pressure and the ability to withstand the hammering;

- resistance to damage mechanical nature due to the absence of gaskets in welded sections;

- uniform heating of the surface and high heat;

- smooth surface prevents dust accumulation;

- easy installation, The ability to lower and side connecting the various accommodations;

- the possibility of temperature control when equipped thermostatic valve.

In addition to fixing, tubular radiators may be equipped spetskronshteynami used as towel.

Also, there is a whole category of models related to the category of designer radiators - they are used to create the interior. These devices can be produced in the form of frames for mirrors or handrails for stairs. Model height from floor to ceiling is successfully used for zoning premises.

Giving intricate shapes radiators, manufacturers increase the competitive attractiveness of their products. But steel batteries shaped railing increases functional load

A lot of positive qualities and excellent characteristics inherent in steel radiators, make their use attractive. Such devices can be easily fit into the interior, they can expand the space visually.

But do not forget about the shortcomings of tubular models, which are as follows:

- low resistance to corrosion processes, especially as manifested at low coolant; corrode spot weld most.

- expensiveness.

As for the cost, the tubular batteries are not low-end solution. To install them often resort designers, who are not constrained in the media in the implementation of their projects.

How to choose the right radiator

One of the important characteristics that influence the choice of heating equipment, power is considered. Besides her there are a number of characteristics that significantly affect the choice of steel panels, to guide their purchase.

The size of the device must correspond to the area of heated space. Excluding certain nuances can be assumed that heating of 1 m2 area required 0.1 kW of heat energy.

Heat transfer devices of steel used in the heating system, is directly dependent on their size. Thus, the length of a radiator installed at the window should be about 60-70% of the width of the window opening.

When selecting the most appropriate model is not superfluous to consider such subtleties:

- considered the most practical devices with manual or mechanical temperature control;

- avoid accidents or reduce the risk of flooding to a minimum allows the installation of the ball valve, which stops the coolant;

- to ensure the efficiency of the heating system is required to periodically remove the air that accumulates inside - is suitable for this purpose Majewski crane.

One of the selection criteria - the reputation of the manufacturer and the additional services offered with the purchase of goods. Thus, preference should be given to those firms that provide services in mounting, operational and service sold steel appliances.

Manufacturers of steel instruments

On heating equipment market steel radiators presented models of many manufacturers, but the manufacturing technology is practically not different, and the cost may be slightly differ.

Steel tubular radiators are assembled from extruded sections, welded together by spot welding

The price of the product is determined by its size, brand design. Often you can buy high-quality domestic appliance, not inferior in performance brand with a worldwide reputation.

Among domestic companies, whose products are in steady demand in our market, as follows:

- Lidea;

- prado;

- Conrad.

Instrument company Lidea produced in Belarus. They are provided with panels 1-2-3, the volume of coolant which is in the range 0,9-6,55 l and depends on the size. Capacity radiator with one panel - 2.1 kW, with two panels - 3.9 kW, with three panels - 5.6 kW. Steel thickness 1.2 mm, operating pressure 8.9 bar.

heating equipment Prado produced in Izhevsk. It is equipped with a 1-2 panels coolant volume varies between 0,8-5,7 l. As for power, then the radiator with one panel - 1.4 kW, with two panels - 2.3 kW. Steel thickness 1.4 mm, operating pressure 8.8 bar.

batteries Conrad made in St. Petersburg. They are equipped with 1-2 panels, the amount of coolant which - 0,85-5,2 liters, depending on the size. The power device with one panel - 1.35 kW, with two panels - 2,3 kW. Steel Thickness 1.4 mm, pressure 10 bar.

Among the European manufacturers of tubular steel panels have proven themselves German and Italian companies: Charlston, Kermi, Arbonia, Israp Tesi.

It is also the most popular panel radiators made in Germany Kermi and Buderus, the Finnish company PURMO. Almost no way inferior to them in quality and popularity of radiators Delonghi from Italy, as well as devices Korado Czech origin.

Models of panel and tubular radiators manufactured in Europe are of different size and capacity. Specifications are given in the passport of each model.

A well-known brand will cost much more expensive equipment from the less popular companies. But buying branded device ensures acquisition device proper European quality

Steel radiators are classified as the most popular space heaters. Thanks presentable appearance, affordable price and high heat transfer, they are widely used in offices, homes and apartments. The maximum lifetime of steel radiators achieved in autonomous heating systems.

Conclusions and useful videos on the topic

Features of the installation and possible wiring diagrams of heating equipment of steel in the video:

Video shows the test heaters from manufacturers on the strength of:

After reviewing the performance and characteristics of steel radiators, you can choose the best option. Especially because of the heating equipment market abounds with models of domestic and foreign manufacturers. The main thing in the pursuit of the perfect form, not to overpay for the product under brand.

Look for steel radiators? Or have experience with these batteries? Leave, please, comment on the article, ask questions and share experiences on the use of steel radiators. Communication unit located below.