Insulating the blind area with penoplex is one of the most common types of repairs. This material protects well from freezing, so there will be no heaving of the soil, and the foundation will remain intact. A step-by-step description of the process and useful tips from the masters can be found in the presented article.

The content of the article

- Why do insulation?

- Preliminary calculations

- Base insulation

- Insulation of the blind area

Why do insulation?

The blind area is created to protect the foundation from freezing, temperature changes and humidity. But it itself also needs insulation, since otherwise the foundation of the house may suffer from soil heaving. In addition, if you insulate the foundation and blind area of the house from the outside with polystyrene foam, you can save on heating.

The advantages of this finish are obvious:

- significant reduction in heat loss;

- protection against deformation and cracks;

- protection from moisture (penoplex practically does not absorb water);

- prevention of mold and rot.

As a rule, insulation of the blind area and foundation is carried out using polystyrene foam. It has high mechanical strength, does not absorb moisture and does not conduct heat. In addition, the material is not attractive to rodents and is resistant to fungus and mold.

It should be understood that insulation of the blind area with foam plastic is not required in regions with a temperate climate, for example, in the south of Russia. But in most areas, even in the middle zone, temperatures in winter can drop to -25 degrees and below. It is especially important to insulate the blind area in the following cases:

- the soil is heaving and has a loose structure;

- shallow foundation;

- high humidity, large amounts of precipitation in different seasons.

Heaving soil creates the most problems. This is the name given to soils with increased mobility due to high moisture levels. When water freezes, the ice expands in volume and reduces the density of the earth. Then, when it thaws, the resulting voids “loose” the soil, which has a bad effect on the foundation. It is the penoplex for the blind area that protects against freezing and, as a result, against heaving.

Preliminary calculations

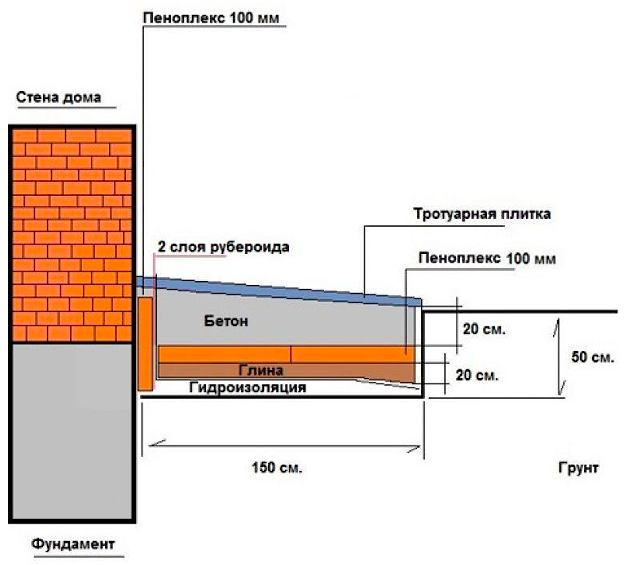

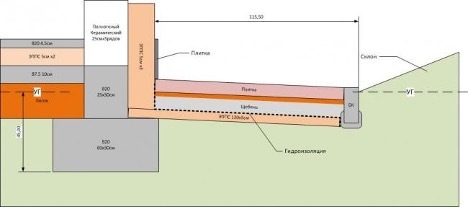

The technology of insulated blind area with penoplex must comply with building codes, in particular SP 82.13330. The requirements are related to the parameters of the blind area:

- minimum tilt angle 3 degrees;

- maximum angle of 10 degrees (it is permissible to do a little more, but walking on such a path will be more difficult, especially after ice);

- width - from 100 cm (not strictly regulated, but 1 m is considered a generally accepted value);

- pit depth 50-60 cm;

- height of sand filling 10-20 cm;

- concrete layer thickness 70-120 cm.

The scheme for insulating the blind area with penoplex should be developed taking into account these parameters. Moreover, a slight deviation is allowed, but the main thing is to make a sufficient slope and ensure a strip width of at least 100 cm. Then it will protect the foundation well, and it will be easy to walk on the surface.

Base insulation

The blind area with penoplex has good heat-shielding properties, and the material is quite durable and lasts 40-50 years. To achieve this result, it is necessary to follow the installation technology. The main stages are:

- A trench is dug along the entire perimeter of the house. Its standard depth is 70-90 cm. But if the house has a cellar or basement, it is better to take 120-130 cm. The width should also be about a meter, so that the person standing in it can work comfortably.

- If you are making a blind area with penoplex around an old house, you will need to carefully inspect the foundation or base. It is thoroughly cleaned of soil residues, and then cracks and irregularities are found and sealed with cement mortar.

- In the presence of large defects, the technology of insulating the blind area with penoplex implies additional plastering of the surface of the base. Thanks to this, the insulation will be in close contact with the entire surface, and the result will be of the highest quality.

- Next, the foundation is covered with bitumen mastic. It must be hot and not contain additional solvent. According to the technology of insulating the blind area with penoplex, it is recommended to apply mastic in several layers. Moreover, you need to wait until the previous layer is completely dry.

- Next, proceed directly to laying polystyrene foam. It is fixed with special glue, and plastic umbrellas are also used (5 pieces per sheet). Adjacent sheets are fixed along the seam - then the insulated blind area with penoplex will be practically airtight.

- A hole is drilled in the wall directly through the insulation block so that they line up exactly. It is recommended to seal these holes with polyurethane foam and insert a plastic dowel.

- The blind area is insulated with polystyrene foam around the entire perimeter, after which it is covered with a waterproofing film. For reinforcement, you can additionally place the mesh on glue. This design additionally protects the penoplex from contact with the ground. But on the other hand, the insulation does not absorb moisture and does not rot.

Insulation of the blind area

Next, they begin to arrange the blind area. To insulate it, proceed as follows:

- Mark a trench of a width that corresponds to the depth of soil freezing. So, in the middle zone it is about 120-130 cm, in Siberia – 180-220 cm.

- Crushed stone is poured onto the bottom. The height of the layer is determined depending on the level of the blind area. If there is groundwater nearby, first lay clay at least 25 cm high.

- Next, a geotextile fabric is placed on the crushed stone with an overlap of 10-15 cm.

- There is sand on top of it - the layer height is 15 cm. It must be compacted manually (with a shield) or using special equipment (vibropressing).

- Penoplex is mounted on an even layer of sand, and two layers are made so that the second covers the joints of the first.

- Waterproofing is placed on top of it, overlapping by 10-15 cm, and glued with tape.

- Finishing is paving slabs or asphalt. You can also make a concrete screed.

Thus, insulation of the base and blind area with extruded polystyrene foam is carried out simultaneously. It is advisable to do this during the construction stage. If the house was built a long time ago, it is important to inspect the foundation and seal seams and cracks. The insulation is placed in two layers, which is especially important for regions with frosty winters. Waterproofing should also be provided, and a concrete screed should be laid as the last layer.