Furniture stores offer many models of frame sofas, but high-quality furniture is quite expensive. You can save a lot if you make a sofa from a bar yourself. But first, you must clearly determine the option of this piece of furniture.

Furniture stores offer many models of frame sofas, but high-quality furniture is quite expensive. You can save a lot if you make a sofa from a bar yourself. But first, you must clearly determine the option of this piece of furniture.

DIY beam sofa

The content of the article

-

DIY beam sofa

- How to choose a beam and prepare

- Tools and materials

- Schemes and drawings

- Assembling a sofa from a bar: step-by-step instruction

All sofas are classified by type of transformation:

- Book. To turn the structure into a bed you need to raise the seat to a certain level and lower it.

- Eurobook. In this case, the seat extends toward itself, and the back is lowered into the space that appears.

- Click-gag. The model makes it possible to set different positions of the backrest at a certain angle.

- Dolphin. To lay out the sofa, you need to roll out the block under the seat, after pulling up to get the second part.

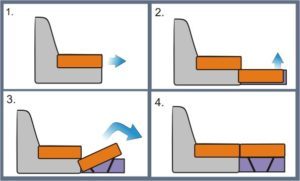

- Cougar. The lower part is rolled forward and mounted on a support, and the second part is installed in the vacated space.

- Cot. You need to pull on a specially fixed loop, and the sofa unfolds like a scroll.

How to choose a beam and prepare

As a rule, a beam of beech, oak, birch, ash, walnut, pine is used. Pine frameworks are the cheapest, but not of good quality, since it is difficult to choose wood of the required cross section and grade. Manufacturers often do not comply with standards. Structures quickly fail due to the fragile frame. It is also important that the timber is well dried, otherwise a fungus will form over time.

The use of birch is a compromise. The material makes it possible to get good quality at an affordable price - birch is slightly more expensive than coniferous varieties of wood, but cheaper than other species.

In some cases, elite types of wood are used, for example, from mahogany. But these products are quite expensive.

Attention! Natural timber is used to assemble the supporting structure of the sofa, which is designed for seating. For sidewalls, glued beams are used.

A quality frame must be made of perfectly smooth bars. All elements must be firmly glued and bolted. Screws are not used, as they quickly lead to loosening of the structure. There are many photos and video instructions that clearly show how a high-quality card frame should look like.

Tools and materials

To build, you will need the following tools:

- Electric Planer.

- Circular Saw.

- Sandpaper.

- Vibratory or belt sander.

- Brushes for varnishing and staining.

- Set verified.

- Drill with a brush nozzle.

- Special glue.

- Wooden pins with a diameter.

- Screwdriver.

- Stain.

- Lacquer.

Schemes and drawings

There are various schemes of sofas, as well as forms and methods of upholstery.

The main components:

- back;

- frame;

- frame;

- fabric lining;

- sidewalls.

Wireframe. For assembly, rails and bars are used. For greater rigidity, plywood sheets or fiberboard are used.

The back is made hollow inside. The shape is most often chosen sloping or rectangular. Side elements are made in the same way as the back.

Fabric lining is done on ready-made patterns or patterns. If they are not, then you can make drawings yourself. Why the facing material is applied to each part of the structure, then the necessary cuts are made.

Attention! During the manufacture of a round sofa, furniture panels are used, which are made of wood or plywood sheets. This material allows the round structure to withstand a sufficient load.

Assembling a sofa from a bar: step-by-step instruction

Stages of manufacturing a frame rectangular sofa:

- First, the frame is assembled. At the base of the frame are wooden bars with a section of 45-55 mm. The design is assembled with a screwdriver and bolts. For fixing wooden elements, special glue is used. Most often, the length of the sofa is chosen within 2.5 m, but you can choose any size.

- Then the frame is assembled from the boards. For convenience, the entire frame structure is interwoven with furniture straps.

- After the back is made, it is sheathed with plywood sheets or any other suitable material. It is advisable to choose the simplest form for the back - a rectangle.

- In the same way, rectangular sidewalls are made of plywood.

- Pasting with foam rubber. In this case, foam mats are needed that need to be glued to the sides and back. After applying the glue, it is left to dry for a certain time.

- A synthetic winterizer is required to mask all irregularities and additionally give volume. First you need to grind all the corners on the frame. After proceeding with upholstery syntepon.

- Covering with facing fabric. A sofa cover can be ordered at the studio. When he is dressed, he is additionally fixed with a furniture stapler.

- Build a sofa. In the end, you need to collect all the elements into one.

If varnishing was chosen instead of the facing fabric, then the varnish should be applied last, when the product is fully assembled. If you try to glue pre-varnished elements, the varnish will reduce the adhesion of the adhesive to the wooden blocks, significantly worsening the joints.

During varnishing, certain rules must be observed:

- The paintwork should be applied in 4-5 thin layers with an intermediate drying of each of them. Do not varnish wooden structures with a thick layer at a time, as the drying time will increase significantly.

- It is advisable to varnish to treat surfaces that are in a horizontal state. This will help prevent drips.

- When the first coat of varnish dries, it is imperative to perform intermediate sanding sanding. The varnish lifts the fibers of the upper layer of the timber, which makes the wood rough to the touch.

Important! If you want to make a sofa "antique", then brushing technology is used.

The steps are as follows:

- First, the front part of all structural elements is processed with a metal brush. The pressure on the brush must be negligible, and its movement - as even as possible. Thus, the soft fibers of the tree are removed, and a relief structure appears on the beam.

- After all surfaces are treated with stain. The number of layers will depend on the desired key.

- The last step is grinding with fine sandpaper. The pressure on the grinding machine must be light. The main task is to sharpen the texture that stands out above the surface, giving it the necessary shade.

Furniture in the spirit of eco-solutions is today the most progressive. Assembling this design does not require much time, and the sofa itself will look quite original and impressive.