One of the most important issues in the autonomous gasification of the house is compliance with the norms and requirements of fire safety. Even at the design stage, you need to clearly know which gas pipes are applicable for outdoor and indoor installation. The successful combination of their various types will ensure maximum reliability of the pipeline.

We will describe how the selection of pipes is made depending on the operating category of the pipeline. We will show you what products are used for laying external branches and internal wiring. Taking into account our recommendations, you will be able to perfectly select the material for the system and monitor the work of hired gas workers.

The content of the article:

- The main classification of gas pipelines

- Types of materials for gas pipes

-

Characteristics and use of steel pipes

- General description of steel products

- Marking of steel pipes

- Features of steel pipelines

- Advantages and disadvantages of structures

-

Features of polyethylene gas pipes

- Methods of joining polymeric structures

- Characteristics of polyethylene pipes

- Advantages and disadvantages of gas polymer pipes

- Nuances of the construction of the copper gas pipeline

- Conclusions and useful video on the topic

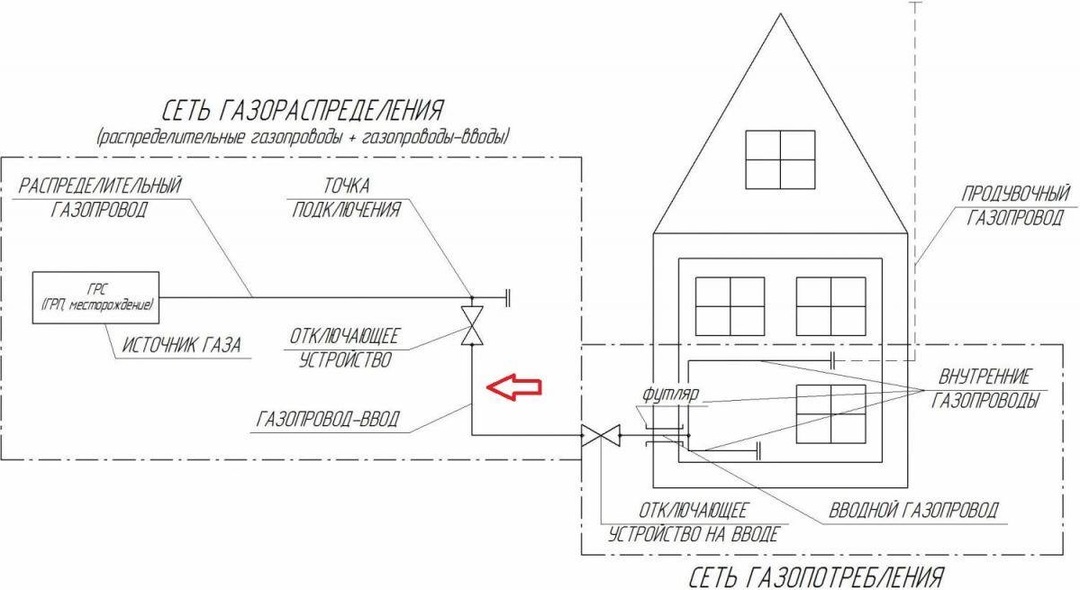

The main classification of gas pipelines

The category of the pipeline, depending on the magnitude of the gas pressure, is one of the most important criteria that have a significant impact on the choice of pipe material.

There are 5 main categories of the gas network:

- IA — design with the highest pressure exceeding 1.2 MPa. The diameter of the pipe is 1000-1200 mm, the purpose is to connect thermal stations, turbines and steam installations.

- I - system with high pressure, which is in the range of 0.6-1.2 MPa. Its purpose is the transportation of gas and the arrangement of gas distribution points.

- II - pressure is lower than in the previous category, but still considered high. It ranges from 300-600 kPa. The diameter of the pipe is 500-1000 mm, the purpose of the gas pipeline is the delivery of gas from gas distributors to industrial facilities, houses for residential and social purposes.

- III - medium pressure design with indicators of 5-300 kPa. Use of pipes with a diameter of 300-500 mm is allowed. Its purpose is to transport gas from the main line to gas distribution points located in residential buildings.

- IV - system with minimum pressure (less than 5 kPa). The diameter of the pipe does not exceed 300 mm, the purpose is to deliver gas from the introductory gas pipeline to residential buildings and directly to final gas consumption devices.

In addition to the category of gas pipeline and pressure values, an important influence on the choice of pipes has the features of their gaskets and operating conditions - external or internal installation, ground or underground.

If they are laid in the ground, you will have to reckon with factors such as depth freezing, density and thickness of the soil layer, the probability of corrosion processes, the presence of stray currents.

An onshore or air gas pipeline is notable for ease of installation work on its creation, but additional maintenance is required for reliable operation.

To ensure stable and durable gas pipeline operation, it is necessary at the preparatory and design work to take into account the features of installation and operation, to perform all the analyzes that prescribe gasification rates.

Types of materials for gas pipes

The main requirements for the gas transportation system are their fire safety, which is achieved by complete sealing of the butt joints. Previously, only steel products were used for the network design, the service life of which depended on the material thickness and pressure in the system.

Today, along with steel pipes, industrial products made of copper and polyethylene are very actively used in the creation and arrangement of gas pipelines. A direct influence on the choice of material has a scope.

So, steel pipes are suitable for aboveground and underground gas pipelines. They are successfully used both for house wiring and for creating high pressure lines. Polyethylene pipes are suitable only for underground installation, and copper - for the installation of gas systems inside apartments and houses.

Polyethylene gas pipelines are successfully replacing steel underground structures of similar purpose due to ease of installation, durability and lower cost.

To find out which pipes can be used to transport gas, it is necessary to become familiar not only with the norms of the device and gas pipeline design, but also to understand the strengths and weaknesses of each of their materials.

Characteristics and use of steel pipes

At present, steel pipelines are the most common. This is due to the high reliability of the material and a wide range of applications.

General description of steel products

The requirements of the construction standards of gasification meet welded pipes with a spiral or straight seam or seamless products of hot or cold rolling. They are ubiquitous and used in construction as trunk pipelines so lines connecting to private houses.

For the manufacture of steel pipes used for gasification, low carbon steel is used (up to 0.25%). Sulfur (content not more than 0.056%) and phosphorus (content not more than 0.046%) are removed from it. This is necessary to give the material the desired properties.

The main parameters of the pipes are the thickness of the steel wall and gas pipeline diameter, which are determined by calculation and depend on the volume of pumped gas and pressure in the system.

Seamless steel pipes are most often used for the device of the high pressure gas pipeline, this is due to the maximum tightness of the joints, which are obtained in the process of connection

In addition to the calculated values, steel pipe rolling must comply with GOST, the main requirements of which are in the following parameters:

- the diameter of the internal gas pipeline should be 25 mm and more;

- pipe diameter for gas distribution systems - 50 mm;

- for the construction of the above-ground gas duct, it is allowed to use the product, in the manufacture of which steel 2 mm thick and above is used;

- the thickness of the steel underground gazovoda should be not less than 3 mm.

In addition to the method of laying a gas pipeline, the seismic and climatic features of the territory where construction is carried out can affect the diameter and wall thickness of steel products.

Marking of steel pipes

Any specialist is obliged to understand the marking of pipes, since there is important information behind a set of simple letters and numbers. So, the abbreviation VGP means that before you is a gas and water pipe, the manufacture of which should be regulated by GOST 3262-75.

The main parameter of the gas pipe is the nominal diameter, marked as a remote control. In manufactured products with remote control 6-150 mm, the standard wall thickness is in the range of 1.8-4 mm. Reinforced pipes are manufactured industrially. Steel is used for their manufacture, the thickness of which can exceed 5.5 mm.

For a package of steel pipes with a diameter of less than 159 mm, a label with a label is posted, by reading which you can find out the full description of the product.

Marking is present directly on the pipe, the thickness of which is more than 3.5 mm, and the remote control exceeds 159 mm. Otherwise, a package of products is marked, on which a label is posted containing information on the length and diameter, and the grade of steel used. Be sure that the label must contain the mark of the manufacturer's QCD.

The letters in the marking of steel pipes correspond to the following parameters:

- P - steel of high accuracy;

- H - the presence of knurled thread;

- Р - presence of the cut thread;

- D - elongated thread;

- M - clutch equipment.

The standard length of steel pipes VGP is 4-12 m. They are called dimensional. With a length of more than 12 m they are called unmeasured.

Features of steel pipelines

Thin-walled light steel pipes are used exclusively in low pressure gas ducts, which are used in gasification of private houses and in the construction of internal wiring. The low weight of the material facilitates the work with pipes and allows you to easily lay the network, which is characterized by complex structural features.

Lightweight products can be bent at a small angle without the help of a pipe bender. Thin-walled steel pipes have a high thermal conductivity, which often leads to the formation of condensate.

It is possible to avoid premature aging as a result of corrosion, if after installing the pipeline their surface is treated with oil paint. The more layers it will be applied, the more effective the steel protection will be. Such products can be easily connected by soldering, and also threaded connections are allowed using fittings.

Threaded connection - the most vulnerable place of the pipeline, for compaction is best to use flax fiber, and after installation check the tightness of the connection by applying soap at the junction solution

If necessary, the device gas outlet, which can withstand the highest pressure, it is customary to use more massive thick-walled reinforced pipes. The highest strength of the pipeline is achieved with high-quality connection of seamless pipes made of steel, by welding, at the final stage the control of connections is mandatory.

Advantages and disadvantages of structures

Due to their physical qualities, steel products are characterized by high strength, and high-quality welding works ensure the reliability and tightness of the seam. They can be considered universal due to the possibility of performing surface and underground installation. And also they are suitable for both indoor and outdoor use.

Along with the positive moments, there are also a number of shortcomings that can not be ignored when choosing pipes and carrying out measures to optimize the life of steel gazovodov:

- the complexity of the installation work;

- low corrosion resistance;

- tendency to the formation of condensate, especially actively manifested in light tubes;

- high mass;

- high cost;

- poor flexibility.

With the observance of building codes, rules of installation, operation and ensuring quality insulation, the uninterrupted operation of a steel gas pipeline will be at least four decades.

Features of polyethylene gas pipes

Along with steel structures in recent years other products are actively used, for the manufacture of which polymeric materials are used.

Installation work on the device of the polyethylene pipeline is performed much faster than in the case of steel pipes, what is explained by the absence of threaded connections and the need to use heavy electric and gas welding equipment.

Methods of joining polymeric structures

Today, the quality of polyethylene pipes makes it possible to build reliable underground gas pipelines with a service life of 80-90 years. Most often, a network of polyethylene materials is arranged for leading the line to private homes.

In addition, such products can be used to transport gas in systems whose pressure does not exceed 1.2 MPa.

To connect the polyethylene pipes butt-end, they need to be carefully centered, heat the edges before melting and connect under pressure, which is set on an adjustable centralizer

The tightness of the connection of polyethylene pipes of good quality is ensured by welding, which can be performed in two ways:

- Pipes whose edges are preheated with a special soldering iron, are mounted end-to-end. Similarly, fittings are mounted. Warming up must be done before viscosity is reached.

- The edges of the product are turned into a special coupling, inside of which there are heating elements. Serving voltage provides heating elements and fixation of pipes in the fitting. The joint obtained by electrofusion welding withstands pressure up to 16 MPa.

If the issue of individual connection to the gas network is decided, then it is better to prefer a cheaper installation option, butt-welding is assumed.

With collective gasification of cottage settlements, dacha societies, villages it is better to resort to more expensive electrofusion welding of polyethylene elements of the gas pipeline. This method provides maximum tightness and reliability of the connection.

Characteristics of polyethylene pipes

Polyethylene pipes are manufactured in diameters from 20 to 400 mm, standard sizes are marked with SDR11 and SDR17,6. Depending on the strength class, there are products marked with PE80 (black with yellow inserts) and PE100 (black with blue inserts).

Polyethylene pipe PE-80 is marked with a characteristic blue line, used for the installation of an underground gas pipeline with low pressure.

PE80 polyethylene pipes are suitable for individual gasification and arrangement of the low-pressure pipeline. In turn, PE100 products have higher strength, and their use is allowed to create gas ducts with a pressure of up to 1.2 MPa.

It should be noted that the installation of PE100 pipes will require great efforts, since they will have to be heated to a higher temperature, however, these costs are compensated for by the excellent connection quality.

Advantages and disadvantages of gas polymer pipes

The steel pipe pipe, popular before, is noticeably replaced by polyethylene analogues.

There are many reasonable explanations for this fact that lie in the useful qualities of PE pipes:

- Good corrosion resistance, ability to withstand exposure to chemically aggressive compounds.

- High strength, resistance to mechanical stress.

- Excellent throughput with no roughness. If you compare the plastic products with steel of the same diameter, then the throughput of the gazovod from PE pipes will be 30% higher.

- Ease of assembly work. Welding PET does not require heavy gas and electric welding equipment, as when installing a steel gas pipeline. In addition, pipes made of polyethylene easily bend, which allows you to bypass the obstacles that arise in the path of the pipeline.

- Low cost of polyethylene products in comparison with similar ones made of copper and steel.

Polyethylene pipes are quite actively used in connecting gas to a private house. This is due to a number of positive qualities. However, there are some features of their use that limit or even completely exclude the possibility of constructing a gas network from polyethylene structures.

Thus, it is impossible to use PET in seismic active zones, in areas where the temperature drops to -45 degrees, in gas pipelines with a pressure of more than 1.2 MPa.

In addition, polyethylene pipes are completely incompatible with network laying in tunnels and collectors, while steel pipes allow this option. It should be borne in mind that when polyethylene is heated to 80 degrees, its deformation occurs and is followed by destruction.

The use of PET is not recommended for creating ground-based gas ducts, since the material is rapidly destroyed by ultraviolet radiation. If, however, a decision has been made about the installation of a land pipeline, the pipes should be coated with a special protective polymer composition.

Nuances of the construction of the copper gas pipeline

Copper pipes have recently begun to be used for the installation of a gas network. It is allowed to use drawn and cold rolled copper pipes with a wall thickness of not less than 1 mm for the implementation of internal wiring.

Copper is a rather expensive material, however, its use is justified by the ease of installation work and the ability to create lines of complex configuration.

Correctly connected copper pipes not only ensure complete tightness of the joints, but also ideally fit into the interior of any room.

Another indisputable fact in favor of copper pipes is their attractive appearance. Since the gas pipeline cannot be hidden in the niches of the walls and ducts, steel structures can easily spoil the appearance of the room, while copper pipes will only enrich the interior.

Copper products have the following positive qualities that may be decisive when choosing them for a gas duct device:

- high plasticity, thanks to which the possibility of laying lines of complex configuration is realized;

- simplicity and ease of installation, the product is easily cut, the connection of pipes is carried out by applying press fittings or soldering;

- attractive appearance;

- durability - the term of operation with the observance of technology reaches 100 years;

- resistance to mechanical damage and resistance to chemically active compounds.

Copper pipes also have their weaknesses, the main one of which is high thermal conductivity, which contributes to the formation of condensate. As well as their strength is much lower than steel, and the price is much higher.

With the technology of brazing copper pipes, providing a tight connection, will introduce next articlewhich we recommend reading.

Conclusions and useful video on the topic

The video demonstrates the process of manufacturing seamless steel pipes:

Electrofusion welding of polyethylene pipes in video:

At present, copper and polymer pipes, although in some cases, are able to compete with steel pipes, they cannot completely replace them. Polyethylene structures are ideal for underground gas pipelines, copper - easy installation. internal wiring, and steel - universal and can be used to create any type of gas network.

Do you have valuable advice on choosing a gas pipe? Want to tell how to arrange the distribution of gas in your home? Please write comments, post photos on the topic, ask questions in the box below.