Today, showers are very popular among consumers. They are set in a private house, in the country, in the apartment - just enough to have a bathroom with a water supply and sewerage system.

Ready designs simply dazzling. Manufacturers equip them with various additional functions, e.g., steam or hydro Turkish bath. Any design, shape, size - from just such a diversity scatter eyes.

However, not every consumer can choose what he likes. Some "Kulibin" begin to imagine and produce showers and some elements of their own hands. Today we'll show you how to make the pallet itself.

What kinds of pallets: shapes and materials

The content of the article

- What kinds of pallets: shapes and materials

- How to make a shower tray with your hands: instructions

- Pros makeshift shower trays

Most importantly, let's understand what a pallet. In fact - this is the basis for the shower stall. For this reason, it makes it the most durable materials.

Finished models are made of different materials. Most often it is:

- Steel. Its products differ low weight and high strength. However, the production of steel enamel is quite fragile and a low level of sound insulation.

- Ceramics. The products have an attractive appearance and is quite simple to use. Among the disadvantages - such products are relatively fragile.

- Cast iron. The products possess the greatest strength, so durable. At the same time, they are heavy, long warm up, which creates a certain discomfort when visiting the soul. they are also quite expensive.

- Fake diamond. High strength and durable material. According to its characteristics is not inferior to natural stone. Has low thermal conductivity, the product is very heavy and is distinguished by its high cost.

- Acrylic. Light, practical material allows you to get an attractive finished product. It perfectly absorbs the noise of falling water. Among the shortcomings can be noted susceptibility to deformation. Also, it is easy to damage.

- Wood. An excellent choice for suburban or country cottage. Environmentally friendly and safe product. The service life of not more than 4 years.

- Plastic. Characterized by the lowest cost. However, more suitable for summer soul than for an apartment or house. Very brittle material.

Each material has its advantages and disadvantages. For example, iron and steel are more durable than acrylic. However, cast iron product has a lot of weight, which can create some discomfort during installation.

The shape of the trays match the most popular configurations of showers. Most often, they are:

- round;

- corner;

- square.

How to make a shower tray with your hands: instructions

Most often, the pallet is made of tiles. This option is one of the budget. For its production enough to have a set of the following tools:

- tool for cutting tiles - suitable for both manual and electrical;

- Master OK;

- roller or brush;

- putty knife;

- Ruler and pencil;

- electric drill.

As for materials, there will need:

- cement;

- sand;

- bricks;

- waterproofing - bitumen suitable fine or special mixtures;

- tile;

- tile adhesive for her;

- self-tapping screws.

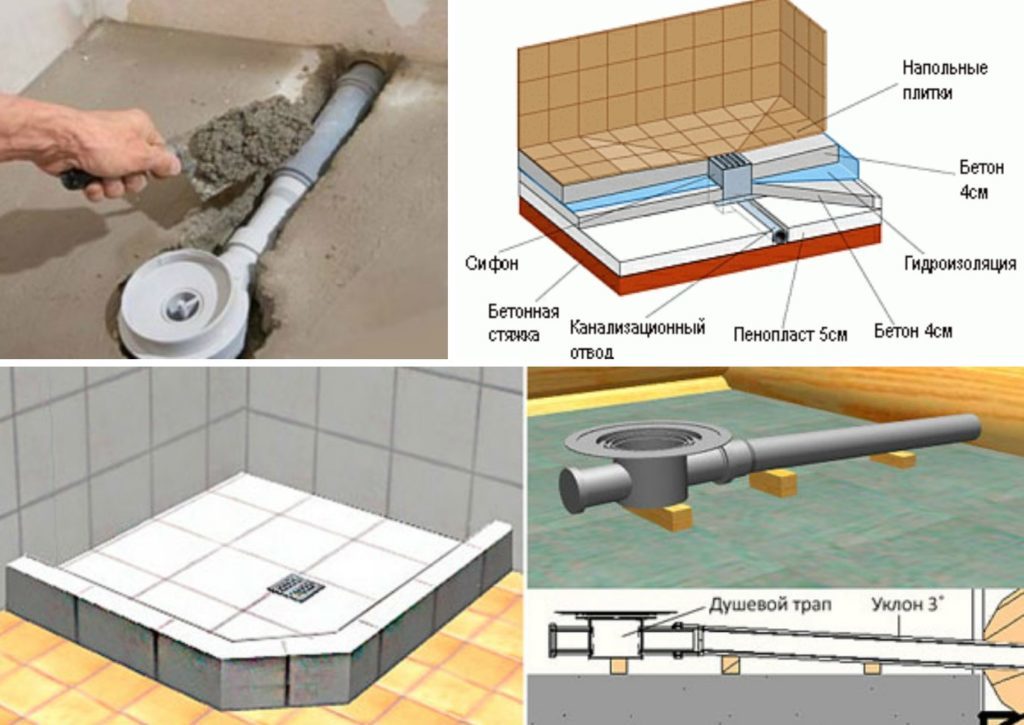

At the first step is to prepare the ground. If the tie is not available, then it needs to perform. Pre waterproofing floor. FROM This task is best cope mastic or foil made of polymer materials. Be sure to make a small entry on the walls.

When the screed is ready and dry, cover it with primer and as waterproofing. This will prevent flooding of spaces below, if any. Also waterproofing protects against fungi, unpleasant odor and eliminates high humidity.

Reference. For extra comfort, the booth base can be equipped with the system "warm floor". Thanks to him, it is not necessary to wait until the tile to warm the water. Also insulate the floor, you can use the expanded polystyrene sheets, which are placed under the tile.

Next, apply a tie layer of a special self-leveling mix. Prime with him and waterproofing. This is especially true of all the corners, joints and seams around the drain hole.

After that, choose the height of the base. It can be almost any and depends only on your wishes and preferences. Do not forget about the need to comply with the slope: it must be more than 3 degrees. For this reason, the pan must not be too low, low design does not allow to comply with this angle.

In most cases, the height of the flanges of the pallet equals one brick. This is to protect the room from the water and is easy to enter the cab. Bumpers can pour cement or made of bricks.

After skirting ready set drain. He has an important and special place in the whole work. If something goes wrong, then after the completion of all work to fix the problem is difficult. So try to immediately ensure high quality.

To do this, follow these steps:

- drain connected to the water drain is necessary with a gradient from three or more degrees - such angle provides the optimum flow rate of the drain and eliminates stagnation in the pipe;

- all joints must be sealed;

- give preference to the pipes of high quality plastic - this material does not corrode and will last for many years;

- Floor drains fix maximum hard;

- the foundation is poured, after you have verified that the construction will be completely immobile and not shift in the future.

When everything is dry, you can deal with surface finish. Optimal variant cladding material - standard ceramic tiles. It allows you to create a variety of patterns, choose any color, suitable for skirting of any material.

stacking technology is no different from laying all types of walls, floors. However, there are a few small nuances. Clay must choose waterproof. During tiling, follow these guidelines:

- the adhesive should be applied with a notched trowel - tool helps to create the "right" surface;

- Glue is applied to the pallet itself, rather than on the tiles;

- press down the tile adhesive so better grasped;

- align the surface with a rubber hammer tapping;

- All joints should be of uniform thickness;

- glue the tiles need from the corner;

- grouting spend until complete drying of the glue.

Pros makeshift shower trays

The tray with his own hands has several advantages over the shop:

- Low cost. Pallet Manufacturing will cost several times cheaper than the purchase and installation of the finished product.

- Any design and shape. You can choose the desired shape, size and height of a future pan.

- Any colors and patterns. tiled finish will pick up not only the color you want, but also to create virtually any patterns. To do this, cut into small enough tile elements. After that you can create.

At each stage, observe calculation accuracy and can withstand the necessary time dry concrete. This will ensure high quality and reliability of the design.

Subscribe to our Social Networks