Everyone is familiar with the situation when, when cutting the same meat, it seems that it is just rubber. Often it’s not the meat at all, it’s just time for someone to sharpen a knife. You can, without further ado, lead them along the touchstone as you hit, and with grief, cut the product in half. But if you want to work with a serviceable, sharpened tool, you need a more serious approach. Today we will talk about how to make a simple and convenient device for sharpening knives.

The content of the article

- What and how they sharpen

- Types of donkeys

- Diagram of a simple and effective knife sharpener

- Sharpening recommendations

What and how they sharpen

Here, it turns out, there are some nuances. Depending on the purpose of the cutting tool, the sharpening angle can vary greatly. Even among kitchen knives, there is a classification by purpose - for meat, bread, vegetables, or for chopping bones. And that's not to mention hunting knives.

@ kitchenwarehq.com

The rule of thumb when choosing a sharpening angle is simple - the smaller it is, the sharper the cutting edge. True, it serves much less, and cutting bones with such a tool, to put it mildly, is not worth it. It is recommended to adhere to the following angles when sharpening:

- For scalpels or razors - from 8 to 12 degrees. With such a tool, you can shave off a mustache or beard, it is no longer suitable for something more serious.

- Fillet knife has a similar sharpening, with an angle of 10-15 degrees.

- For slicing bread or vegetables do already from 15 to 20 degrees.

- Utility and hunting knives, as a rule, sharpened at an angle of 20-25 degrees. If the blade is thick enough, you can also give a 40-degree sharpening, then you can safely chop branches and open cans.

- If we are talking about machete or ax, the blade is sharpened at 30-50 degrees. Cutting bread with such a tool is problematic, but cutting down a branch, liana and even the trunk of a small tree is quite possible.

There are also universal tools with different sharpening angles. With their fine-tuning, the situation is quite difficult. In order not to suffer with maintaining the desired inclination of the blade, it makes sense to make a device with a changeable angle of inclination of the donkey.

Types of donkeys

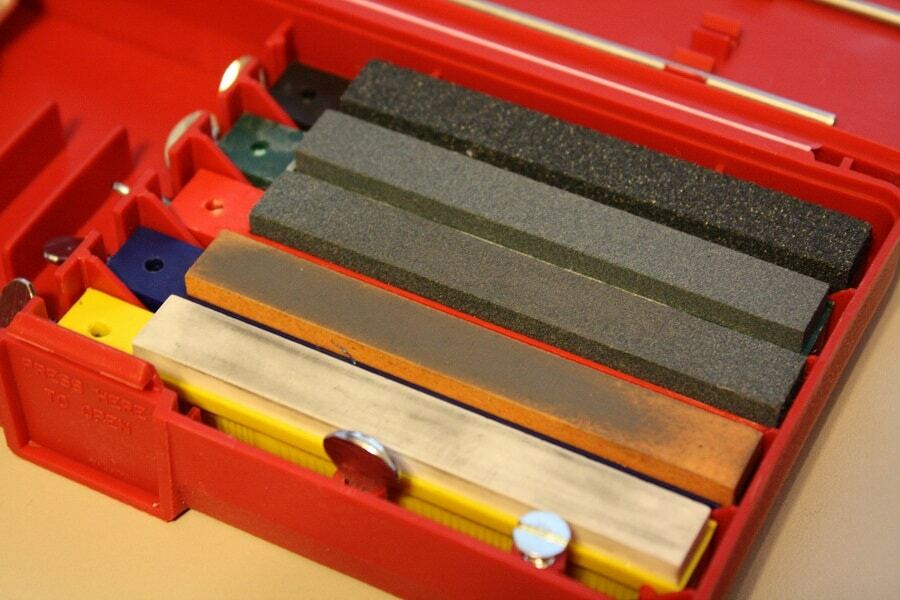

The classification is based on two criteria - the origin of the material and its grain size. According to the material, the touchstone can be shale, corundum, ceramic or diamond (industrial diamond grain).

@ backpackingmastery.com

Before use, corundum and shale whetstones are moistened with water or soapy water. Part of the abrasive that has moved away from them during the sharpening process forms a kind of paste, which contributes to the finishing of the blade. It is noteworthy that fine abrasive stones are rarely found among stones made of this material. They serve much less than ceramic or diamond ones.

By granularity The abrasive is usually classified according to the number of grains per square inch of surface:

- 200 to 250 - very rude, is used for straightening completely damaged cutting edges, for example, at an ax.

- From 300 to 350 - rude, also used when profiling an edge and changing the sharpening angle. If there are no obvious chipping on the blade, it makes no sense to apply it.

- From 400 to 500 - average, a rather exotic species, is found in only a few producers. By and large, it is easy to do without it.

- 600 to 700 is the most common small abrasive. Most often used on the farm.

- From 1000 to 1200 - very small. Serves for the final finishing of the blade and its polishing.

Some bars have different grain sizes on different sides. For work, it is enough to have one touchstone of medium and fine grain. For the sharpening process to be relatively convenient, the block should be at least twice as long as the blade.

Diagram of a simple and effective knife sharpener

There are a great many designs for sharpening a knife. We will not bother ourselves with questions of aesthetics, but we will approach from a practical point of view. I.e with minimal labor costs - maximum result.

@ stroychik.ru

To make adaptations you will need:

- four wooden blocks, 200x50x20 mm in size;

- four bolts with wing nuts;

- touchstone;

- self-tapping screws for wood from 70 mm;

- drill;

- screwdriver;

- protractor.

Two corners at 90 degrees are assembled from the bars onto self-tapping screws. In them, in the same place relative to each other, holes for bolts are drilled, 3-4 in different places on each bar. It turns out a kind of a touchstone holder. The angle at which it is clamped is set using a protractor. Clamping is carried out using wing nuts.

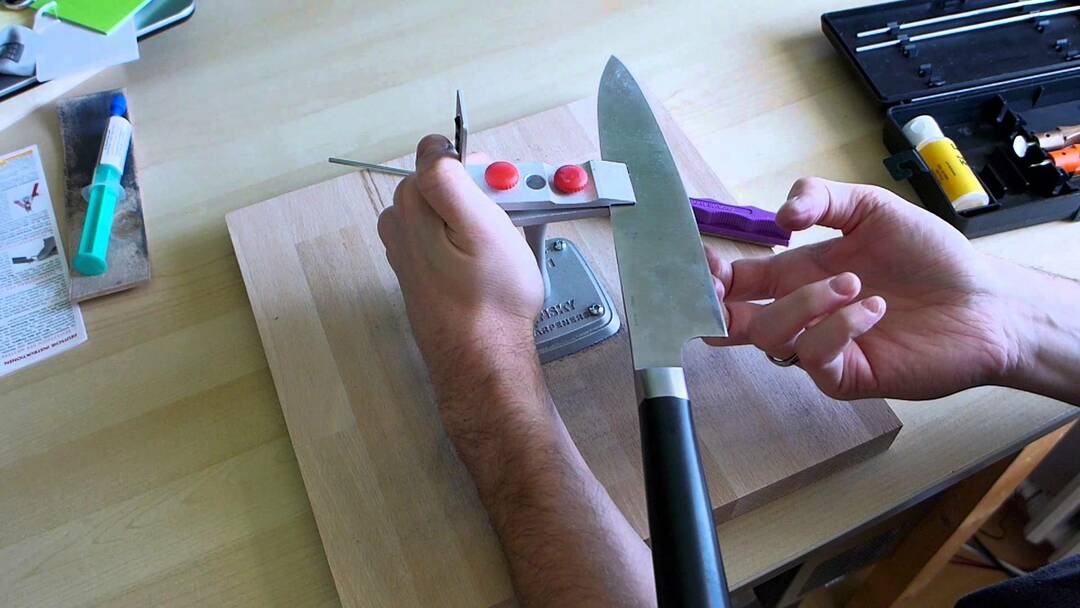

For all its seeming simplicity, the design is very easy to use. Whatever the sharpening angle, the knife blade is positioned and held in a vertical plane.

Sharpening recommendations

@ alloutdoor.com

Let me remind you briefly for those who do not understand this issue:

- The process begins with a coarser abrasive, then bringing the blade to a fine one. Before starting sharpening, we make sure that the bar is securely fastened in the clamp.

- The angle at which the touchstone is clamped is half that required. For example, when sharpening a hunting knife at 40 degrees, set 20 on the protractor.

- The movement of the knife begins from itself, keeping the plane of the blade perpendicular to the donkey. When sharpening a knife closer to its edge, the blade has to be turned to maintain a right angle.

- The tip should not break off the plane of the touchstone at the end of the movement, and also smoothly return back.

- Sharpening is carried out until burrs appear on the back of the blade, after which the knife is turned over. It is desirable that the burrs are uniform over the entire length of the cutting edge.

- After a full cycle has been carried out with the second side (again there is a burr on the opposite side), the abrasive is changed to a finer one.

After finishing the touchdown, some use leather belt with goy paste, achieving perfect polish. In this case, the knife is led along the belt with a blunt edge forward, so as not to damage the skin and spoil the product.

In a word, no higher mathematics. A little practice - and soon neighbors will come to you asking them to sharpen their knives.

Subscribe to our Social Networks