An ideal way to escape from all worries, to relax after a hard day's work is a rocking chair. But someone may be scared off by the high price of the finished product, while someone cannot find the best option for themselves. Why not try making it yourself?

We will tell you how to do this in our article. Consider how to assemble a rocking chair made of wood with your own hands, what tools and materials are needed for this. Here are detailed instructions for assembling three different options, providing them with drawings, visual photos and videos.

The content of the article:

- Features of the design of the rocking chair

-

Preparation of tools and materials

- Stage 1 - selection of wood

- Stage 2 - preparation of tools

- Stage 3 - chair model selection

- №1. Making a chair out of plywood

- №2. Assembling a chair from planks

- №3. Chair made of cable reel

- Videos and useful videos on the topic

Features of the design of the rocking chair

The peculiarity of the chair lies in its design: two parts curved in the form of an arc, which are attached to the legs. The design of the chair itself, its upholstery, shape can be different.

In addition to a pleasant stay, rocking chair owners note that rocking such a rocking chair can help with various health problems. For example, in people with irregular heart rhythms, regular rest in such a chair improves and stabilizes the heartbeat. Also, during the swing, most of the muscles are relaxed, and the muscles of the back and legs are subjected to special training.

A rocking chair is made of various materials: metal, wood, plastic. One example of the successful use of a rocking chair as an interior decoration

Preparation of tools and materials

Most often, it is wood that is used to make such a chair, or it is combined with metal or plastic. Because wood is an environmentally friendly material that fits perfectly into almost any interior. At the same time, high-quality wood is capable of emitting the smell of freshness and forest for a long time.

A wooden product is easier to process, even handcrafted, which allows you to achieve the perfect result during the manufacturing process. And also wood has a rather low price compared to other materials.

Stage 1 - selection of wood

When creating a rocking chair, coniferous wood is especially popular.

It has several advantages:

- Light weight, which makes it easier to move the finished product later.

- Ease of manufacture. Low density of the material itself, which facilitates the manufacturing process.

- Possibility of manual processing. Coniferous wood lends itself to easy manual processing.

- Low cost, when compared with other types of wood.

The wood itself has a light shade. The main disadvantage is that during rain, high humidity, the wood can swell, increase in size.

If you have enough funds for more expensive species, such as oak, beech, then it is better to take them, because the wood of these varieties has no pores, therefore they have a higher strength.

It is not enough to choose a suitable species, it is important to monitor the moisture content of the wood. Especially at the initial stage. If it is not dry enough, it is better to give it a little time to return to its usual state, otherwise after drying the tree can deform, change its appearance, and you, as a result, simply lose money spent on acquisition.

Stage 2 - preparation of tools

When making a rocking chair out of wood, you will need the following tools:

- An electric jigsaw (the blade must be fine-toothed) for cutting out blanks of the future product.

- A planer for processing blanks.

- Grinder.

- Wood glue (Moment, PVA or other).

- Hammer.

- Dowels wooden.

- Ties for fastening parts when gluing.

- Drawing tools (square, tape measure, pencil).

- Stapler building.

- Brush.

If you plan to varnish or paint the finished product after assembly, then it is advisable to also prepare respirator.

Stage 3 - chair model selection

In the photo below you can see various options for a rocking chair made of wood, which everyone can make at home.

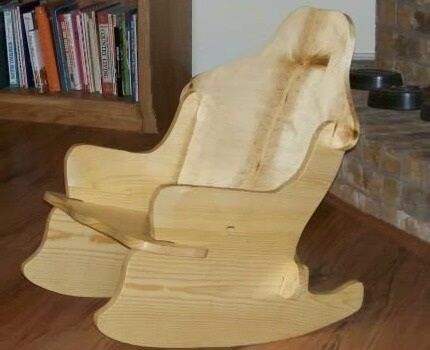

You can make such a chair with your own hands. This option is ideal for young children.

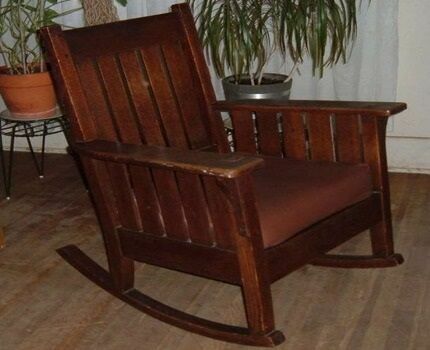

A comfortable and nice armchair can become not only functional furniture, but also an interior decoration. It is important to choose the fabric for the seat to match the interior

It remains to choose the appropriate option and you can start making it.

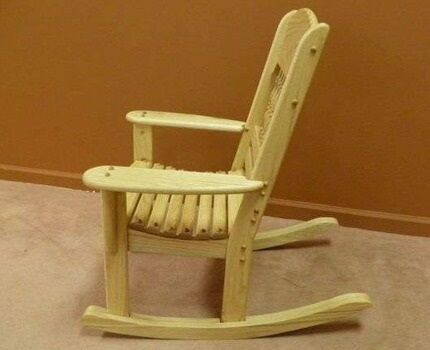

Such an armchair can be used to decorate a veranda, a gazebo, or to relax in the garden. For greater comfort, the seat can be fitted with a suitable cushion

This version of the rocking chair will perfectly complement the interior. It is soft and comfortable - the seat and backrest are equipped with soft cushions. You can even take a nap in such an armchair.

We will consider the process of making a rocking chair using the example of the latter option - chairs with a soft seat and back.

№1. Making a chair out of plywood

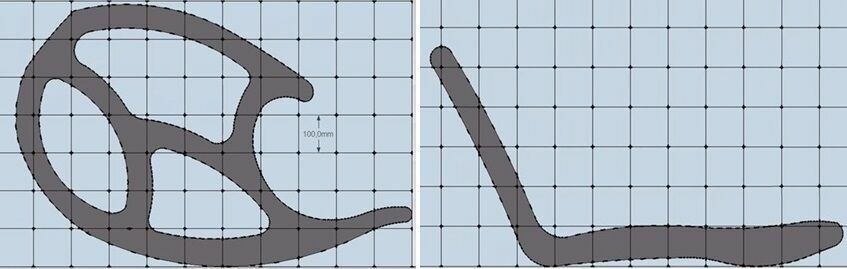

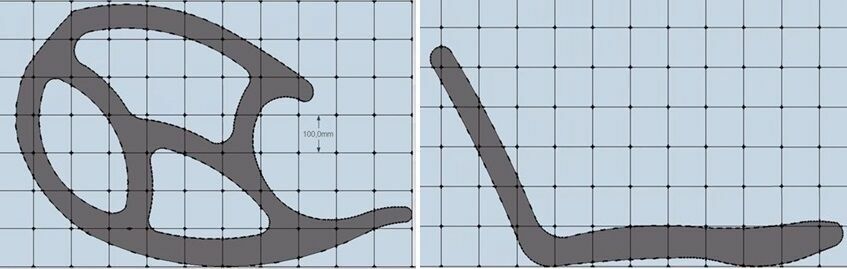

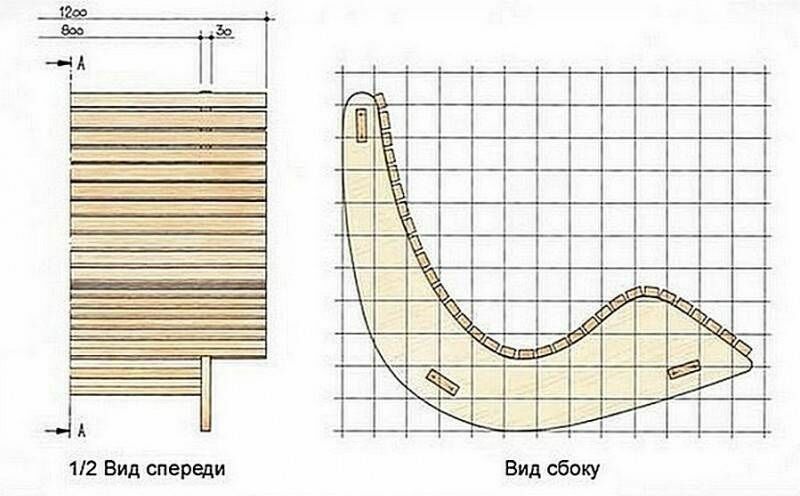

First, you need to prepare a transparent film with checkered markings (cage length 100 mm), since we will trace the outline of the blanks from the drawings for wood along it.

You will need a wooden sheet of 29800 (14900 * 2) mm² (with correct and rational markings, the area may be smaller). Its thickness is approximately 20 mm.

The most important thing is to draw well and correctly the rounded parts of the chair. This is a very important part, a mistake in the elaboration of which can ultimately affect the quality of the entire chair.

Thus, to create this model of a rocking chair, you will need:

- Plywood sheet 20 mm about 30,000 mm² for the main parts in the drawing and additional boards (about 1600 rubles);

- Foam rubber sheet for the seat (300-400 rubles);

- Dowels (200 rubles packing);

- Seat fabric (400 rubles, depending on the type of fabric);

- Glue PVA or another (100 rubles);

- Acrylic paint (450 rubles);

- Acrylic varnish (200 rubles);

- Acetone (150 rubles);

In total, 3500 rubles, which is several times cheaper than ready-made chairs, plus everything you will have the opportunity to do everything "for yourself", that is, in the way that suits you best.

First trace the outline of the part with a marker, and then cut it out of the film. A utility knife is best.

Using the stencils cut out from the film, draw out the contours of the blanks with a marker on the tree. After that, in the places of the inner cutouts, we drill holes for more convenient work with a jigsaw or a hacksaw.

It is best if you attach two boards, fasten them together and cut two blanks at the same time, so you will definitely get the same parts.

After cutting out all the parts, you will need to carefully grind the ends, while not damaging or breaking off small particles along the contour. It is very important that the legs of the chair are very smooth, even, so you can achieve the most smooth swing when resting on the chair.

You have already cut and finished the main parts of the chair, now you need to cut the planks for the seat itself. The length and width of the boards may vary depending on your body type. Recommended sizes: 70-80 mm in width and from 500 mm in length. You will need 6 such blanks. And one is about 100-120 mm wide, which will be the very top. They also need to be sanded and processed.

Next, on each side part, we drill 7 pairs of recesses for fastening with dowels. The location of the grooves is shown in the photo, try to maintain the same distance between each pair.

It is best to mark half of the dowel length on the drill with duct tape so you can drill to the ideal dowel depth.

Now you need glue. Can be used PVA, but you can Moment, which you like best. It is necessary to lubricate both the holes themselves and dowels.

Next, fasten the side parts together with the help of sawn boards. In order for the structure to hold tightly, you need to fix it in this position with the help of ties. And leave to dry.

In the meantime, you can drill holes in the two legs that will be attached to the side walls. In total, 6 holes need to be drilled on each side - 3 in the leg and 3 in the side piece.

In this state, it is worth leaving everything for about a day, maybe more for a couple of hours, depending on the temperature and humidity in the room.

Now you need to decide if you will paint the chair or keep the natural wood color. In principle, both options are good in their own way, but here you need to correctly choose the color and style of the interior. If you want to use a rocking chair in a country house or cottage, it is better to leave it as it is, but in an apartment it will be appropriate to have a painted product.

If you do decide to paint the chair, then you will need a separate painting room. Perform all painting work in a respirator..

The first step is to clean the surfaces of dust and degrease with acetone. Next, we prime in one, maximum two, primer coats. Aerosol acrylic will do.

After the primer has dried, you can start painting itself. If using spray paint, shake the can for about 30 seconds before use. After covering with the first coat of paint, wait about 20 minutes until it dries, and then you can proceed to the second coat. When painting wood, it is recommended to apply 3 coats of paint.

Now, to complete the work, it remains to cover the surface with acrylic varnish. It dries for about 3 hours, so take your time, it's better to wait longer than ruin everything.

If you do not want to paint in some color, but want to keep the natural one, then do the same thing, only skipping the painting process. Use the varnish immediately. You can take alcohol or oil based paints.

After painting, you can start attaching the side walls and legs, which will allow the chair to swing

Thus, the rocking chair is assembled, but the only thing missing is the seat upholstery, which can be made of foam rubber. Then you need to take a fabric that is pleasant to the touch and a color that matches the interior.

With the help of construction stapler fix it all on the chair itself. Well, that's all, the rocking chair is ready!

№2. Assembling a chair from planks

We have disassembled a rather classic version of a rocking chair, but this is far from the only option. Therefore, consider a few others.

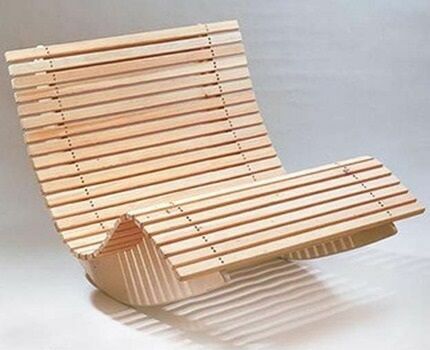

If you want to do something more interesting, more creative, then you can try this one. A whimsical shape, soft curves - such a chair will fit well both into the interior of the room, and will become a decoration of the veranda

To create it, you will need all the same tools, but slightly different materials. Here it is already worth using a hammer and nails to fasten the parts together.

Drawing of parts for the manufacture of the original model of a rocking chair made of wood. The length of each cell in the drawing is also 100 mm.

№3. Chair made of cable reel

Another option is also possible, which will also be a little non-standard - a rocking chair made of a cable reel.

A rocking chair can be made from an old cable reel with just a little redesign. It turns out to be a rather creative but functional product.

First you need to disassemble the coil itself, separate its parts from each other. Then, using a tape measure, mark the holes for future fastening rods.

This must be done in this way: in the middle of the segment of the central edge of the coil, it is drilled to the other edge the first hole, and the other two are made at an equal distance and at an equal angle relative to the first holes.

Nothing terrible will happen, even if you do not quite accurately, since these rods will not participate in the construction of the seats, they only additionally fasten the side parts, which already hold well, the rods serve as a guarantee of strength constructions. The rods are secured with nuts on each side

After that, we proceed to mount the planks for the seat itself. You can leave them as they were before the coil was disassembled. It is recommended to additionally glue them PVA glue and leave to dry for a day. You also need to fix the boards with tape for now so that they are held correctly and not beveled.

After the glue has dried, you can proceed to fastening the second side wall. First, you just have to grease the boards with glue. Next, we securely twist and fasten both walls with rods. And now, the rocking chair is ready! If desired, you can also paint and make the seat upholstery.

Didn't you like any of the offered models? You yourself can come up with something interesting and make a rocking chair from any available means. The most important thing is the strength of the chair so that you do not get injured while relaxing.

In addition to making an armchair, we have other instructions on how to assemble furniture at home on our website - cabinet making, bed assembly and sofa with drawers.

Videos and useful videos on the topic

In this video, the author very clearly and competently explains the whole process of creating a rocking chair. The video is divided into several sections, including theory, stages of the practical part:

In this video, the author shows in 6 minutes the whole process of creating a rocking chair, while everything is very simple and clear. Details are drawn for each person individually, using the tools at hand:

The video was shot by an ordinary schoolboy who was able to make a rocking chair in the workshop of his school. The video shows all the stages of work. The student used standard tools that almost everyone has (an electric jigsaw, screwdriver, grinder), so it's easy to repeat this work:

We looked at several options for making a wooden rocking chair at home. The finished product will be several times cheaper than the purchased one, but at the same time it will not be inferior to it either in functionality or in design. Choose one of the proposed methods or come up with something of your own - it's up to you!

Still have questions about making a rocking chair? Or do you want to share the results of your labors? Add a photo of a homemade rocking chair, tell us about your personal experience in assembling it - the comment form is located below. Also here you can take part in the discussion, express your opinion on the advisability of making such furniture with your own hands.